Chapter 4 Parameters|

Revision Jan. 2009, 06EE, SW--PW V1.12/CTL V2.12 4-157

Group 10: PID Control

A. Common applications for PID control

1. Flow control: A flow sensor is used to feedback the flow data and perform accurate flow control.

2. Pressure control: A pressure sensor is used to feedback the pressure data and perform precise

pressure control.

3. Air volume control: An air volume sensor is used to feedback the air volume data to have excellent

air volume regulation.

4. Temperature control: A thermocouple or thermistor is used to feedback temperature data for

comfortable temperature control.

5. Speed control: A speed sensor or encoder is used to feedback motor shaft speed or input another

machines speed as a target value for closed loop speed control of master-slave operation.

Pr.10.00 sets the PID setpoint source (target value). PID control operates with the feedback signal as

set by Pr.10.01 either 0~+10V voltage or 4-20mA current.

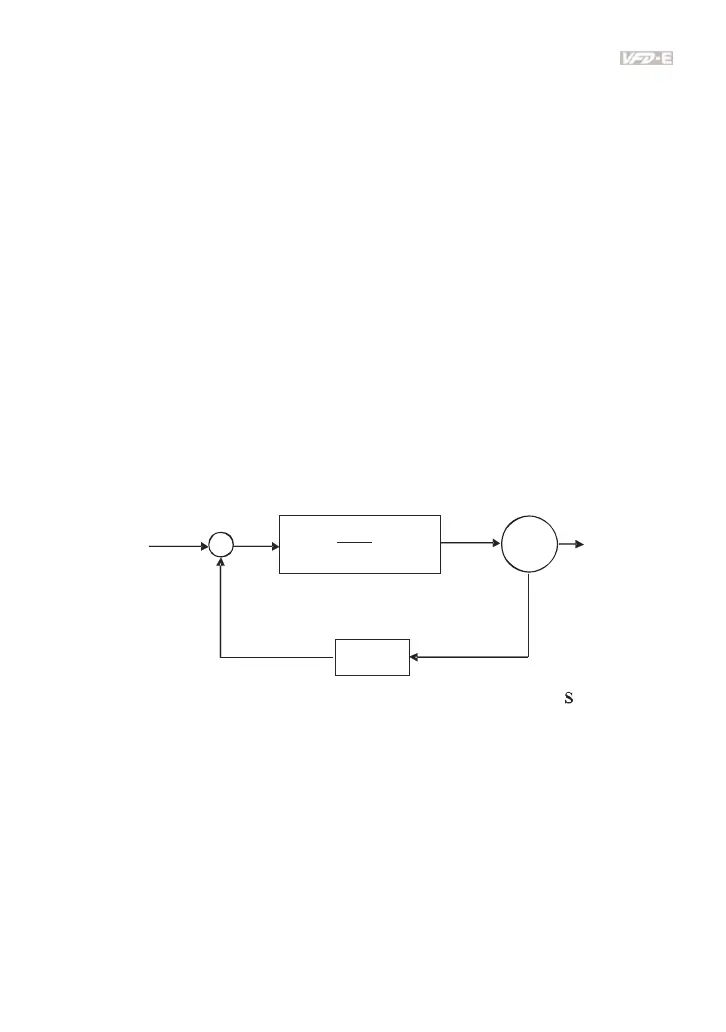

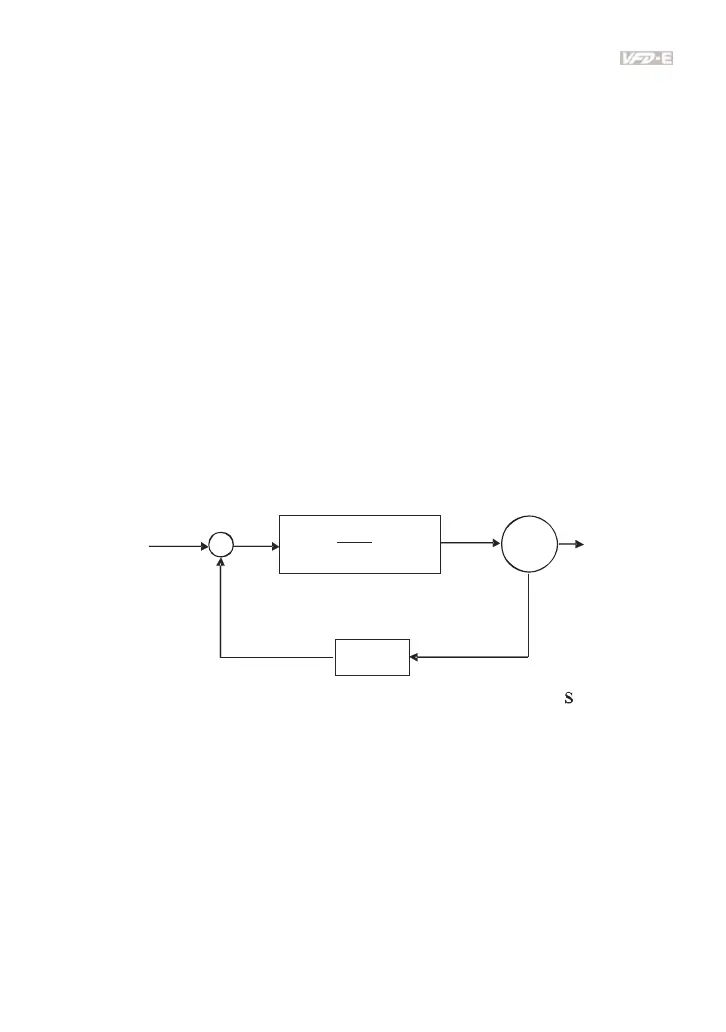

B. PID control loop:

S)T

ST

1

(1K

d

i

p

×+

×

+

IM

+

-

Setpoint

drive execute PID control

output value

feedback signal

sensor

p

K

: Proportional gain(P)

i

T

: Integral time(I)

d

T

: Derivative control(D)

: Operator

C. Concept of PID control

1. Proportional gain(P): the output is proportional to input. With only proportional gain control, there

will always be a steady-state error.

2. Integral time(I): the controller output is proportional to the integral of the controller input. To

eliminate the steady-state error, an “integral part” needs to be added to the controller. The integral

time decides the relation between integral part and error. The integral part will be increased by time

even if the error is small. It gradually increases the controller output to eliminate the error until it is 0.

In this way a system can be stable without steady-state error by proportional gain control and integral

time control.

Loading...

Loading...