Chapter 4 Parameters|

Revision Jan. 2009, 06EE, SW--PW V1.12/CTL V2.12 4-63

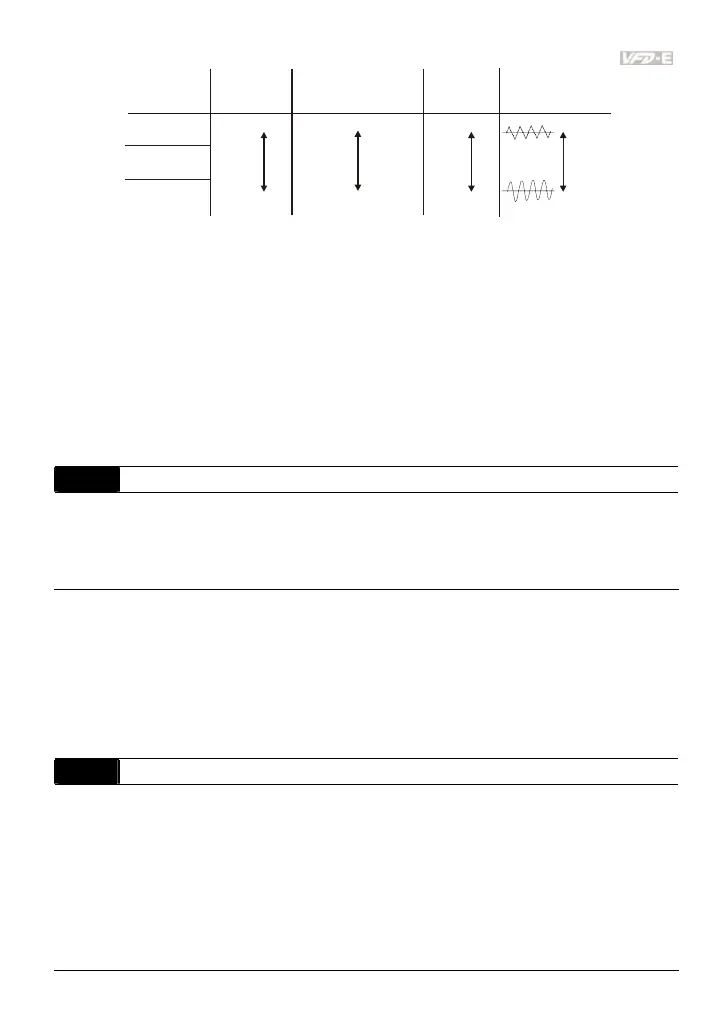

1kHz

8kHz

15kHz

Carrier

Frequency

Acoustic

Noise

Electromagnetic

Noise or leakage

current

Heat

Dissipation

Current

Wave

Significant

Minimal

Significant

Minimal

Minimal

Significant

Minimal

Significant

From the table, we see that the PWM carrier frequency has a significant influence on the

electromagnetic noise, AC motor drive heat dissipation, and motor acoustic noise.

The PWM carrier frequency will be decreased automatically by heat sink temperature and

output current of the AC motor drive. It is used as a necessary precaution to prevent the AC

motor drive from overheating and thus extends IGBT’s life. If the user wants to fix carrier within

the rated range and won’t change by the change of the surrounding temperature and

frequently load. Please refer to Pr.02.18 for Selection of Carrier Modulation.

Related parameters: Pr.02.18(Selection of Carrier Modulation) and Pr.03.08(Fan Control).

02.04 Motor Direction Control

Factory Setting: 0

Settings 0 Forward/Reverse operation enabled

1 Reverse operation disabled

2 Forward operation disabled

This parameter is used to disable one direction of rotation of the AC motor drive direction of

rotation to prevent damage due to operation errors.

The motor direction also can be limited by setting one of Pr.04.05~04.08 to 21.

Related parameters: Pr.04.05(Multi-function Input Terminal (MI3)), Pr.04.06(Multi-function

Input Terminal (MI4)), Pr. 04.07(Multi-function Input Terminal (MI5)) and Pr.04.08(Multi-

function Input Terminal (MI6))

02.05 Line Start Lockout

Factory Setting: 1

Settings 0 Disable. Operation status is not changed even if operation

command source Pr.02.01 is changed.

1 Enable. Operation status is not changed even if operation command

source Pr.02.01 is changed.

2 Disable. Operation status will change if operation command source

Pr.02.01 is changed.

3 Enable. Operation status will change if operation command source

Pr.02.01 is changed.

Loading...

Loading...