20

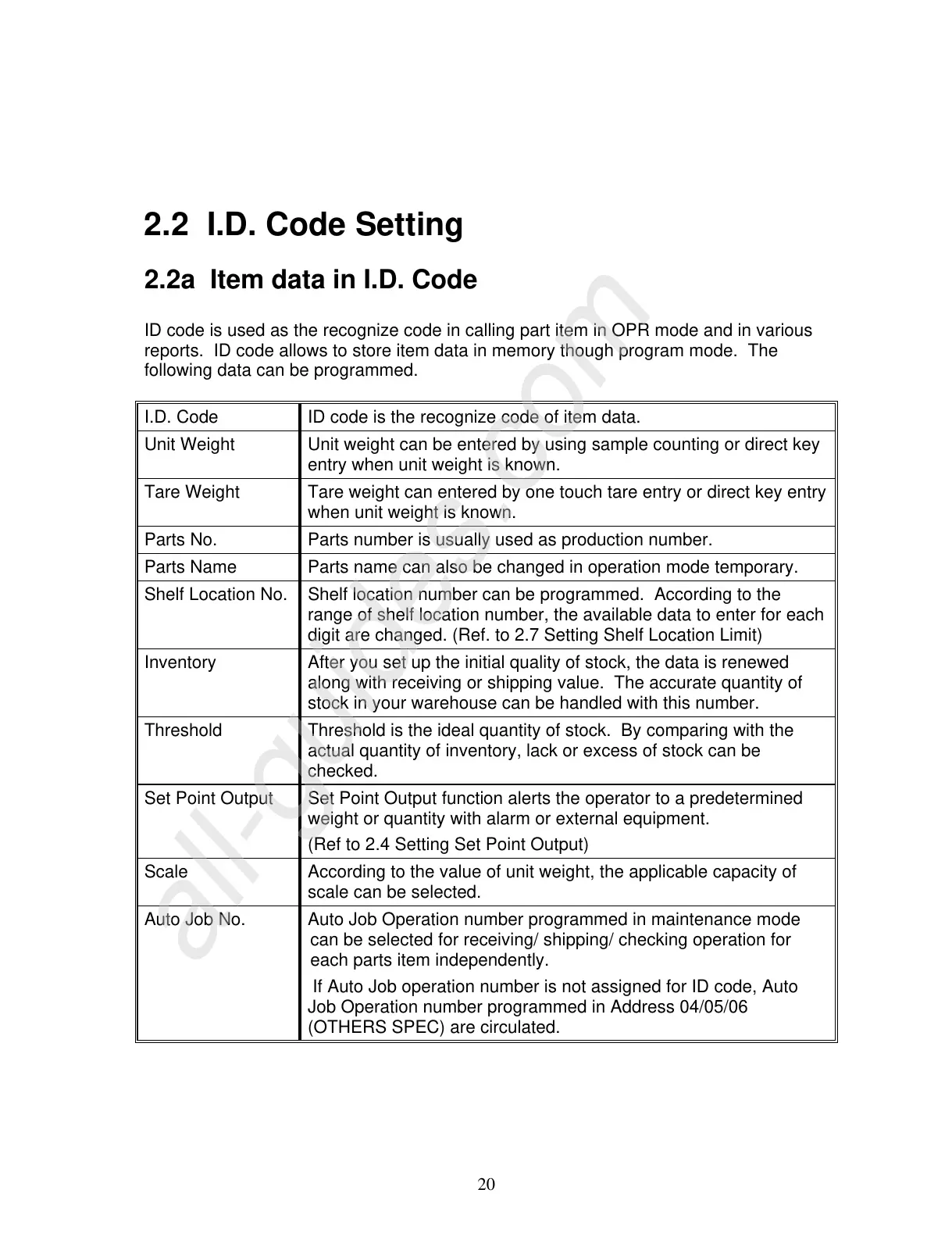

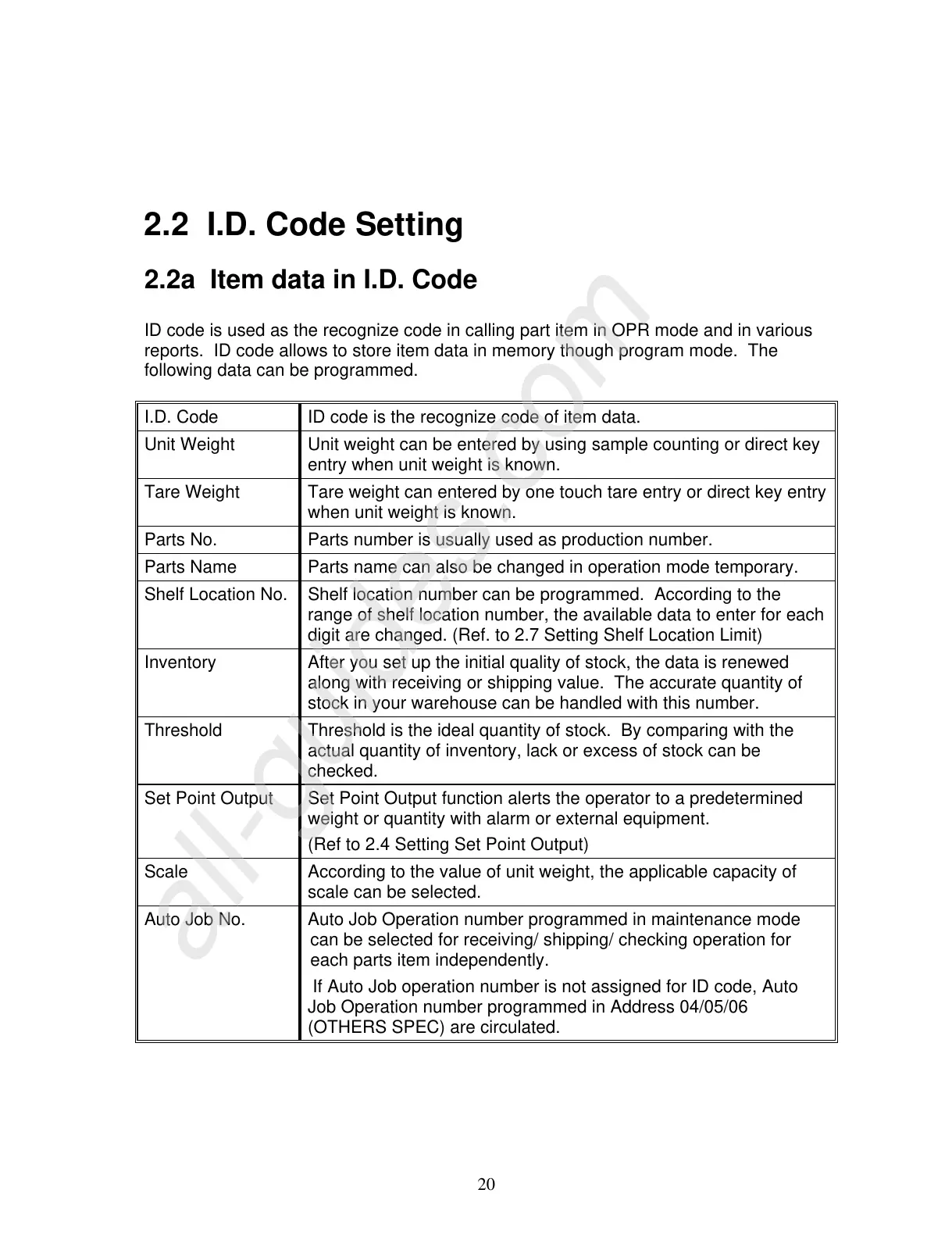

2.2 I.D. Code Setting

2.2a Item data in I.D. Code

ID code is used as the recognize code in calling part item in OPR mode and in various

reports. ID code allows to store item data in memory though program mode. The

following data can be programmed.

I.D. Code ID code is the recognize code of item data.

Unit Weight Unit weight can be entered by using sample counting or direct key

entry when unit weight is known.

Tare Weight Tare weight can entered by one touch tare entry or direct key entry

when unit weight is known.

Parts No. Parts number is usually used as production number.

Parts Name Parts name can also be changed in operation mode temporary.

Shelf Location No. Shelf location number can be programmed. According to the

range of shelf location number, the available data to enter for each

digit are changed. (Ref. to 2.7 Setting Shelf Location Limit)

Inventory After you set up the initial quality of stock, the data is renewed

along with receiving or shipping value. The accurate quantity of

stock in your warehouse can be handled with this number.

Threshold Threshold is the ideal quantity of stock. By comparing with the

actual quantity of inventory, lack or excess of stock can be

checked.

Set Point Output Set Point Output function alerts the operator to a predetermined

weight or quantity with alarm or external equipment.

(Ref to 2.4 Setting Set Point Output)

Scale According to the value of unit weight, the applicable capacity of

scale can be selected.

Auto Job No. Auto Job Operation number programmed in maintenance mode

can be selected for receiving/ shipping/ checking operation for

each parts item independently.

If Auto Job operation number is not assigned for ID code, Auto

Job Operation number programmed in Address 04/05/06

(OTHERS SPEC) are circulated.

Loading...

Loading...