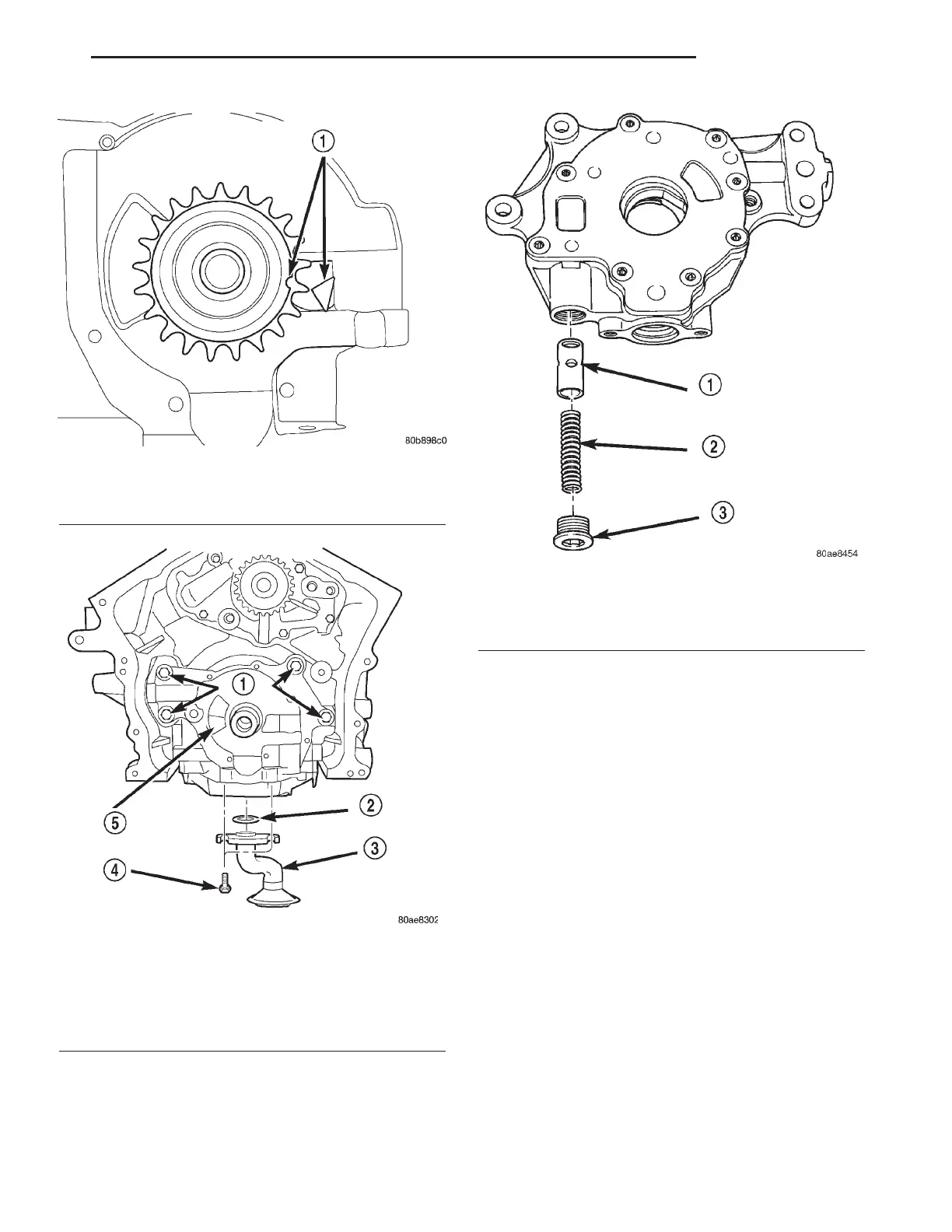

CAUTION: Oil pump pressure relief valve must be

installed as shown in (Fig. 96) or engine damage

may occur.

(2) Remove spring and relief valve.

(3) Remove oil pump cover screws and lift off cover

plate (Fig. 97).

(4) Remove pump rotors.

(5) Wash all parts in a suitable solvent.

(6) Inspect components carefully for damage or

wear. (Refer to 9 - ENGINE/LUBRICATION/OIL

PUMP - INSPECTION)

CLEANING

(1) Clean all parts thoroughly in a suitable sol-

vent.

INSPECTION

(1) Disassemble the oil pump. (Refer to 9 -

ENGINE/LUBRICATION/OIL PUMP - DISASSEM-

BLY)

(2) Clean all oil pump components. (Refer to 9 -

ENGINE/LUBRICATION/OIL PUMP - CLEANING)

(3) Inspect mating surface of the oil pump housing

and cover. Replace oil pump if deeply scratched or

grooved (minor surface scratches and polishing is

normal).

(4) Lay a straightedge across the pump cover sur-

face (Fig. 98). If a 0.025 mm (0.001 in.) feeler gauge

can be inserted between cover and straight edge,

cover should be replaced.

Fig. 94 Crankshaft Positioned At 60 DEGREES

ATDC No.1 Cylinder

1 - CRANKSHAFT POSITION = 60° ATDC NO. 1 CYLINDER

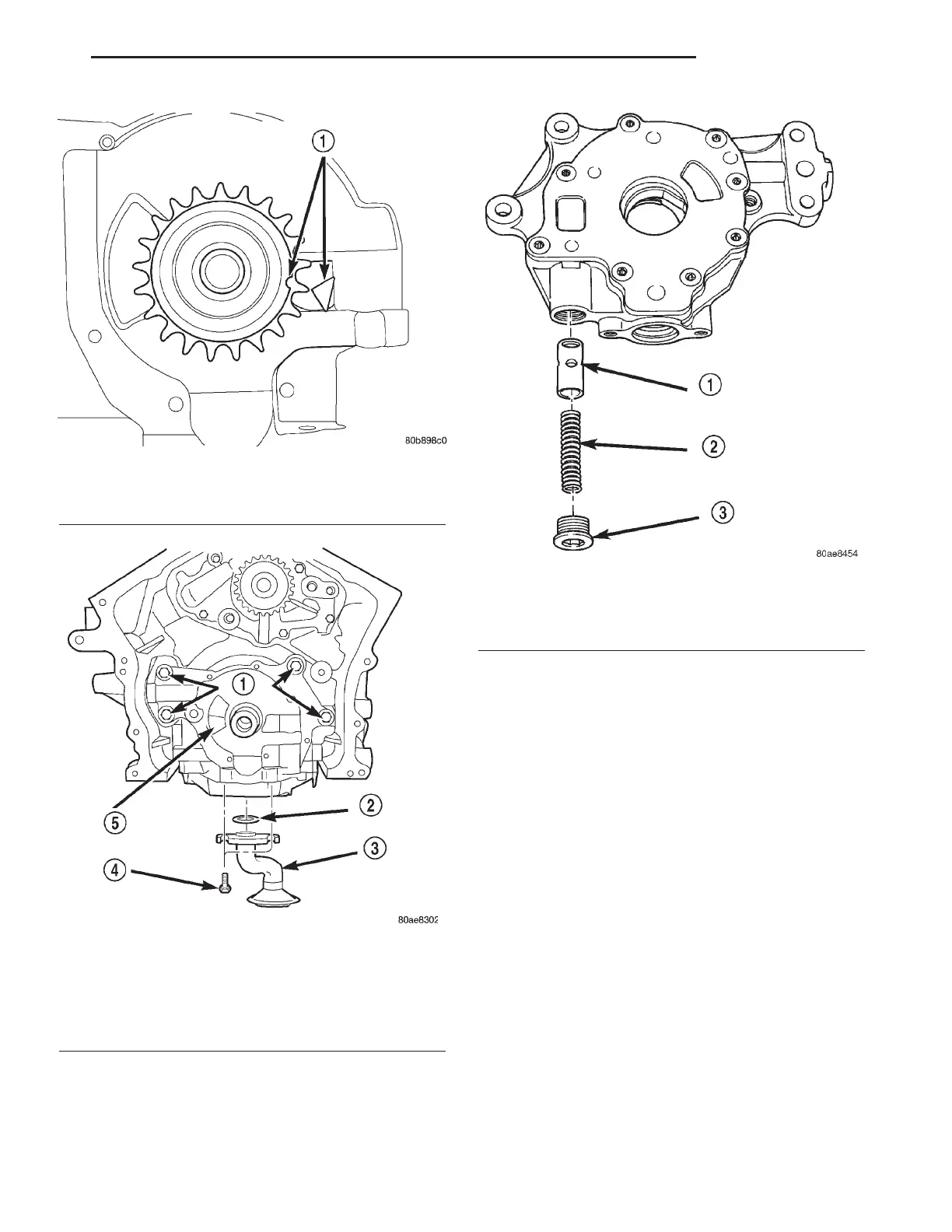

Fig. 95 Oil Pump and Pick-up Tube

1 - BOLTS

2 - O-RING

3 - PICK-UP TUBE

4 - BOLT

5 - OIL PUMP

Fig. 96 Oil Pressure Relief Valve

1 - RELIEF VALVE

2 - SPRING

3 - RETAINER CAP

LH ENGINE 2.7L 9 - 69

OIL PUMP (Continued)

Loading...

Loading...