NOTE: Multi-Layer Steel (MLS) head gaskets require

a scratch free sealing surface.

Remove all gasket material from cylinder head and

block (Refer to 9 - ENGINE - STANDARD PROCE-

DURE). Be careful not to gouge or scratch the alumi-

num head sealing surface.

Clean all engine oil passages.

INSPECTION

(1) Before cleaning, check for leaks, damage and

cracks.

(2) Clean cylinder head and oil passages.

(3) Check cylinder head for flatness (Fig. 12).

(4) Cylinder head must be flat within:

• Standard dimension = less than 0.05 mm (0.002

inch.)

• Service Limit = 0.2 mm (0.008 inch.)

• Grinding Limit = Maximum of 0.2 mm (0.008

inch.) is permitted.

CAUTION: 0.20 mm (0.008 in.) MAX is a combined

total dimension of the stock removal limit from cyl-

inder head and block top surface (Deck) together.

INSTALLATION

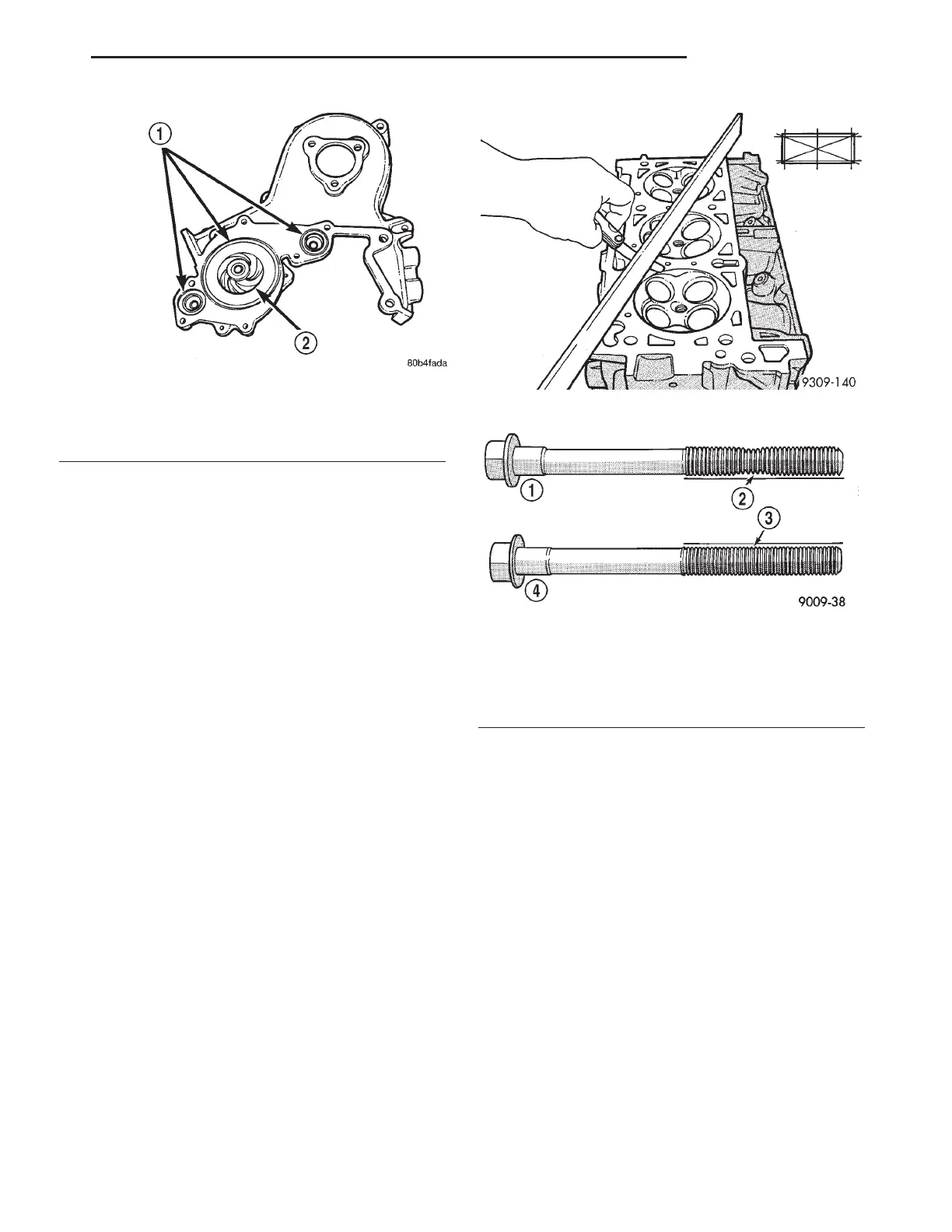

The cylinder head bolts are tightened using a

torque plus angle procedure. The bolts must be

examined BEFORE reuse. If the threads are

necked down the bolts must be replaced (Fig.

13).

Necking can be checked by holding a scale or

straight edge against the threads. If all the threads

do not contact the scale the bolt must be replaced.

CAUTION: When cleaning cylinder head and cylin-

der block surfaces, DO NOT use a metal scraper

because the surfaces could be cut or ground. Use

ONLY a wooden or plastic scraper.

(1) Clean sealing surfaces of cylinder head and

block.

CAUTION: Ensure that the correct head gaskets are

used and are oriented correctly on cylinder block.

The 3.5L engine head gaskets have perfectly round

combustion sealing rings. The 3.2L engine does

NOT have perfectly round combustion sealing

rings.

(2) Install head gasket over locating dowels.

Ensure the gasket is installed on the correct side of

engine (Fig. 14).

(3) Install cylinder head over locating dowels.

(4) Before installing the bolts, lubricate the

threads with engine oil.

(5) Tighten the cylinder head bolts in the sequence

shown in (Fig. 15). Using the 4 step torque-turn

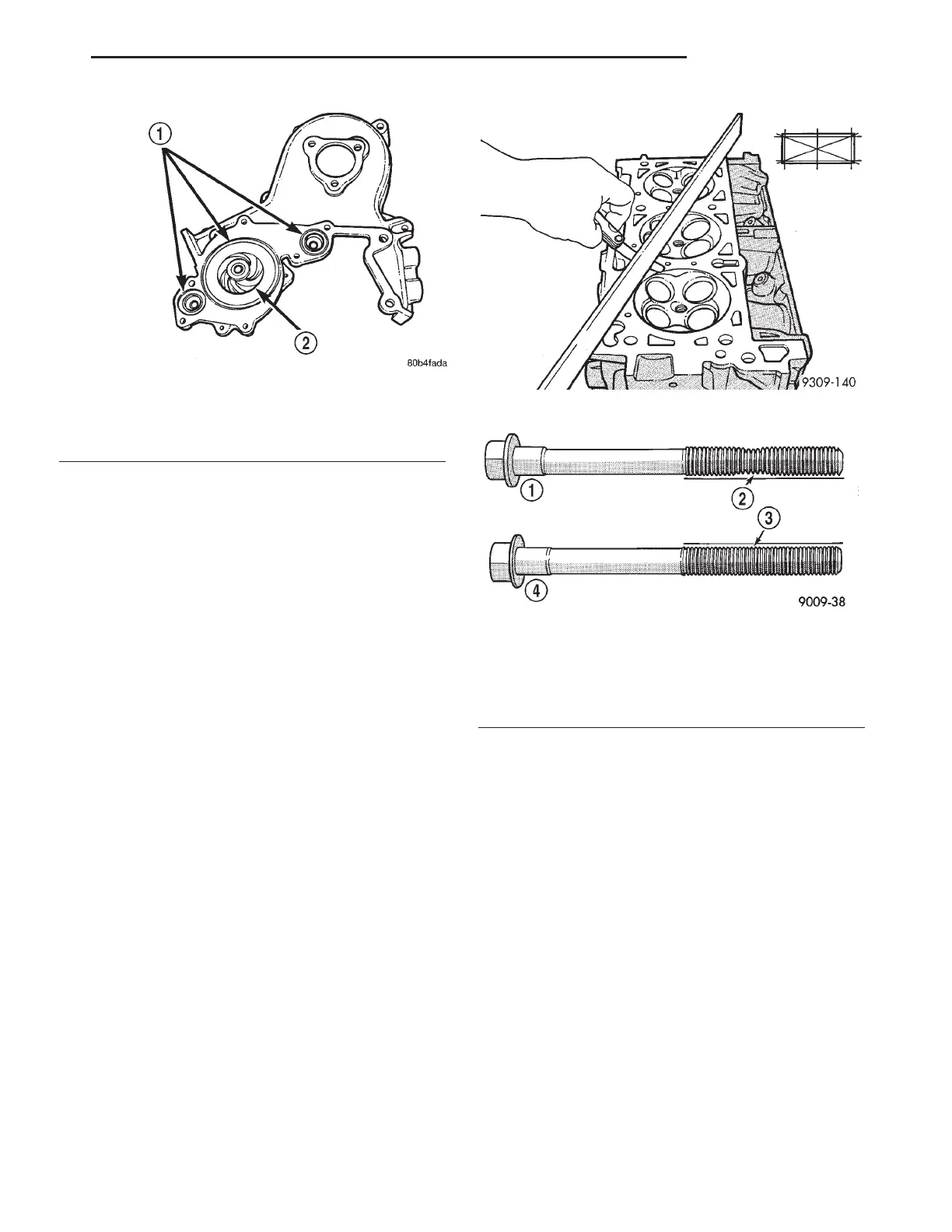

Fig. 11 Right Side Timing Belt Cover Water Pump

O-Rings

1 - O-RINGS

2 - WATER PUMP IMPELLER

Fig. 12 Checking Cylinder Head Flatness

Fig. 13 Checking Bolts for Stretching (Necking)

1 - STRETCHED BOLT

2 - THREADS ARE NOT STRAIGHT ON LINE

3 - THREADS ARE STRAIGHT ON LINE

4 - UNSTRETCHED BOLT

LH ENGINE 3.5L 9 - 111

CYLINDER HEAD (Continued)

Loading...

Loading...