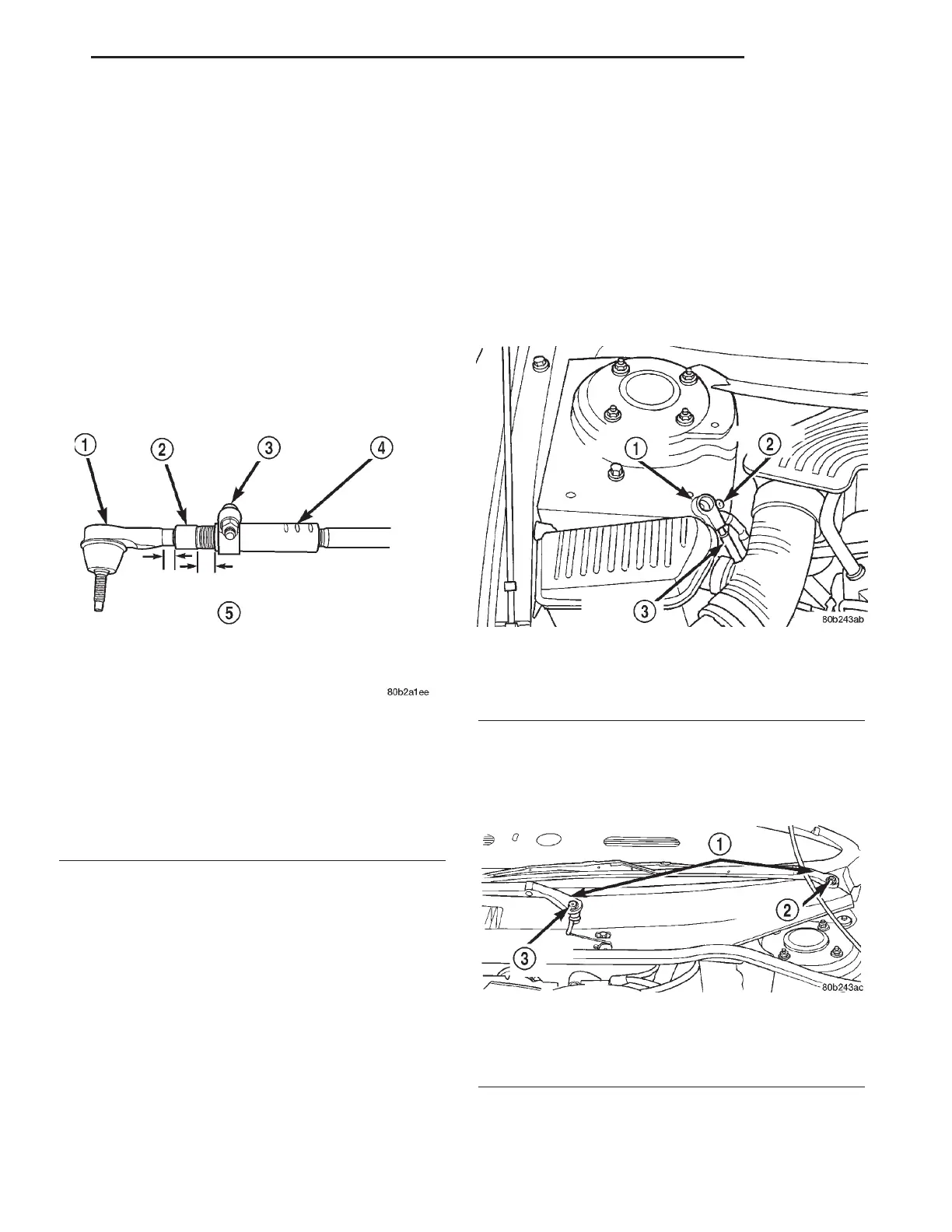

CAUTION: When setting the front Toe on the vehi-

cle, the maximum dimension of exposed threads

allowed on the adjuster and outer tie rod cannot

exceed the distance shown in (Fig. 49). If the maxi-

mum distance is exceeded, inadequate retention of

either the adjuster or the outer tie rod can result.

This condition can cause separation of the outer tie

rod end from the inner tie rod. Ensure that adjust-

ment sleeve pinch bolts are torqued to the required

specification when Toe setting procedure is com-

pleted.

(6) Check the front wheel toe setting on vehicle

and make required changes. When making front

wheel toe adjustments, be sure the maximum

exposed thread requirements (Fig. 49) are not

exceeded.

CAUTION: When torquing the adjuster pinch bolt,

the following procedure must be followed to ensure

adequate retention of the adjuster is obtained. Not

following this procedure, could result in the Toe

Setting Adjustment changing and/or the separation

of the outer tie rod from the inner tie rod.

(7) After completion of the tie rod end installation

and the toe adjustment procedure, tighten adjuster

pinch bolt (Fig. 49) to a torque of 38 N·m (28 ft. lbs.).

Make sure the outer tie rod maintains correct per-

pendicular orientation while tightening the adjuster

pinch bolt.

BUSHING - INNER TIE ROD

REMOVAL - INNER TIE ROD BUSHING

NOTE: When servicing inner tie rod bushings,

replacement of both inner tie rod bushings is rec-

ommended.

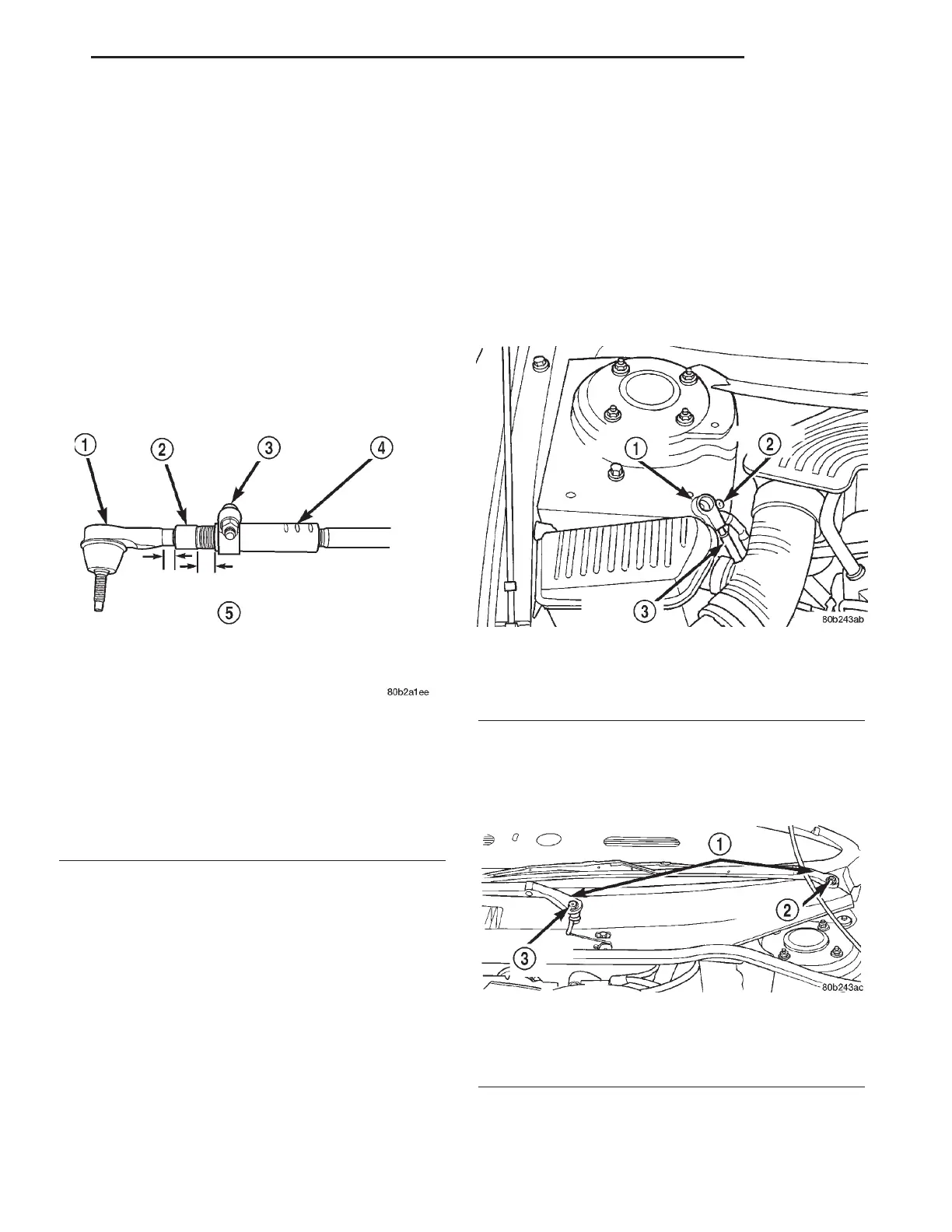

(1) Remove the battery ground cable from the

ground stud on the shock tower and isolate the

ground cable by installing the cable isolator on the

ground stud (Fig. 50).

(2) Remove caps from both wiper arms at the

attachment to the pivots to expose the wiper arm

attaching nut. Remove the nut attaching each wiper

arm to its pivot (Fig. 51).

Fig. 49 Tie Rod Thread Engagement Requirements

1 - OUTER TIE ROD

2 - ADJUSTER

3 - PINCH BOLT

4 - INNER TIE ROD

5 - ALLOWABLE THREADS EXPOSED ON OUTER TIE ROD AND

ADJUSTER IS A MAXIMUM OF 20 MILLIMETERS. REFER TO

AREA INDICATED ABOVE ON THE OUTER TIE ROD AND

ADJUSTER.

Fig. 50 Correctly Isolated Remote Ground Cable

1 - CABLE ISOLATOR

2 - GROUND STUD

3 - GROUND CABLE

Fig. 51 Wiper Arm Attachment To Pivot

1 - WIPER ARMS

2 - ATTACHING NUT

3 - ATTACHING NUT

LH GEAR 19 - 47

TIE ROD - OUTER (Continued)

Loading...

Loading...