CONNECTING ROD BEARINGS

STANDARD PROCEDURE - CONNECTING RODS

AND BEARINGS

CONNECTING ROD BEARINGS

The bearing caps are not interchangeable and

should be marked at removal to insure correct

assembly.

The bearing shells must be installed with the

tangs inserted into the machined grooves in the rods

and caps. Install cap with the tangs on the same side

as the rod.

Fit all rods on one bank until complete.

Limits of taper or out-of-round on any crankshaft

journals should be held to 0.015 mm (0.0006 in.).

Bearings are available in standard, 0.025 mm (0.001

in.), and 0.254 mm (0.010 in.) undersizes. Install the

bearings in pairs. Do not use a new bearing

half with an old bearing half. Do not file the

rods or bearing caps.

(1) For measuring main bearing clearance and con-

necting rod bearing clearance use plastigage (Fig.

56). For more information on using plastigage (Refer

to 9 - ENGINE - STANDARD PROCEDURE). Refer

to Engine Specifications for bearing clearance specifi-

cations (Refer to 9 - ENGINE - SPECIFICATIONS).

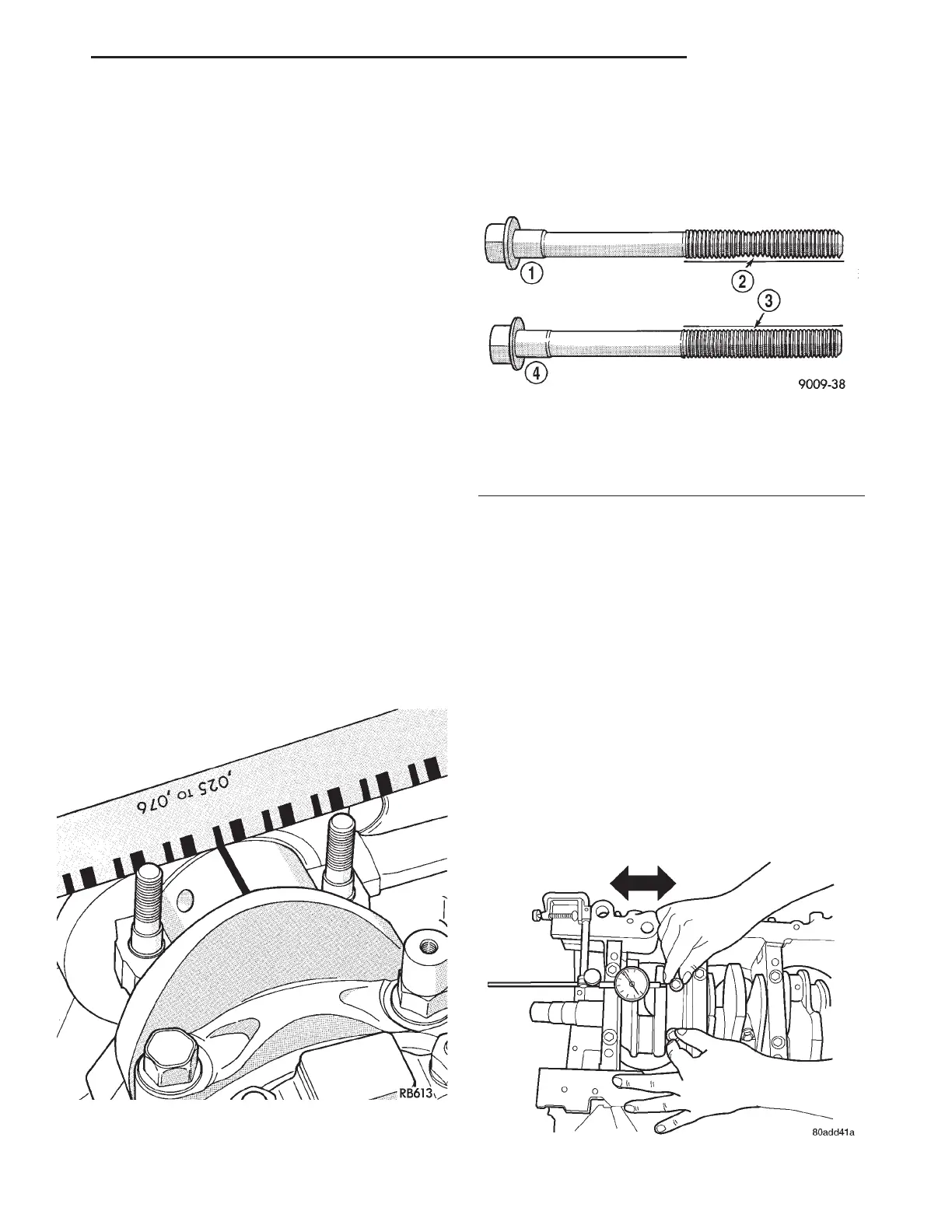

NOTE: The rod bearing bolts should be examined

before reuse. If the threads are necked down the

bolts must be replaced (Fig. 57).

CONNECTING ROD BOLTS

(1) Examine connecting rod bolts for stretching.

Stretching can be checked by holding a scale or

straight edge against the threads. If all the threads

do not contact the scale the bolt must be replaced.

(2) Before installing the nuts the threads should

be oiled with engine oil.

(3)

Install nuts on each bolt finger tight. Then alter-

nately torque each nut to assemble the cap properly.

(4) Tighten the connecting rod cap nuts to specifi-

cations. (Refer to 9 - ENGINE - SPECIFICATIONS)

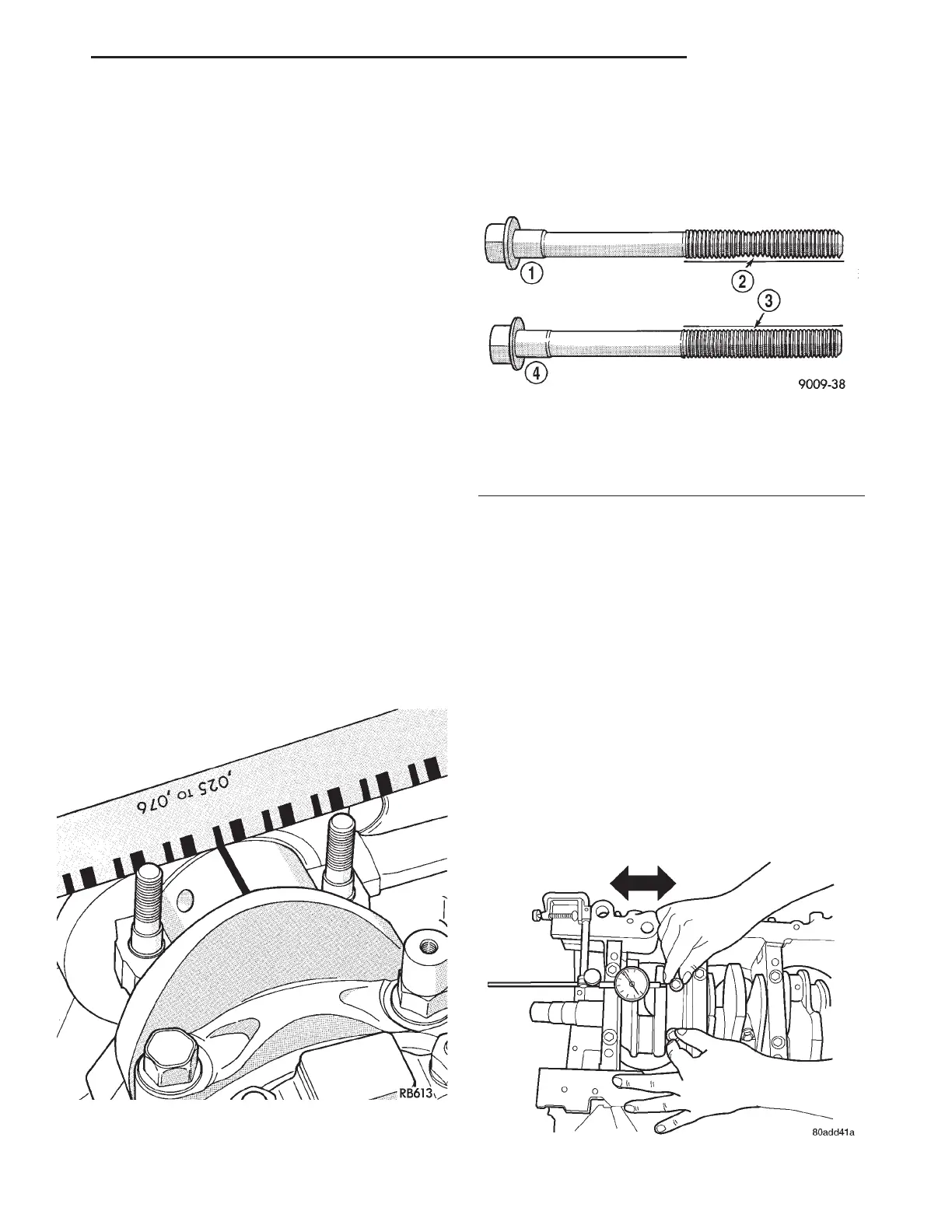

CONNECTING ROD SIDE CLEARANCE

(1) Mount a dial indicator to a stationary point on

engine. Locate probe perpendicular to and resting

against the connecting rod cap being checked. Move

connecting rod all the way to rear of its travel. Zero

the dial indicator. Move connecting rod forward to

limit of travel and read the dial indicator (Fig. 58).

Compare measurement to specification listed in

engine specifications (Refer to 9 - ENGINE - SPECI-

FICATIONS). Repeat procedure for each connecting

rod. Turn crankshaft for connecting rod accessibility.

Fig. 56 CHECKING CONNECTING ROD BEARING

Fig. 57 CHECK FOR STRETCHED BOLTS

1 - STRETCHED BOLT

2 - THREADS ARE NOT STRAIGHT ON LINE

3 - THREADS ARE STRAIGHT ON LINE

4 - UNSTRETCHED BOLT

Fig. 58 CONNECTING ROD SIDE CLEARANCE

LH ENGINE 3.5L 9 - 129

Loading...

Loading...