MAIN BEARING SELECTION CHART—3.2/3.5L

Main Bearing Bore Grade

Marks

123

A

(3)

standard

(2) +003

mm

(+0.0002

in.)

(1)

+0.006

mm

(+0.0003

in.)

Crankshaft

Main Journal

Grade Marks

B

(4)

-0.003

mm

(-0.0002

in.)

(3)

standard

(2) +003

mm

(+0.0002

in.)

C

(5)

-0.006

mm

(-0.0003

in.)

(4)

-0.003

mm

(-0.0002

in.)

(3)

standard

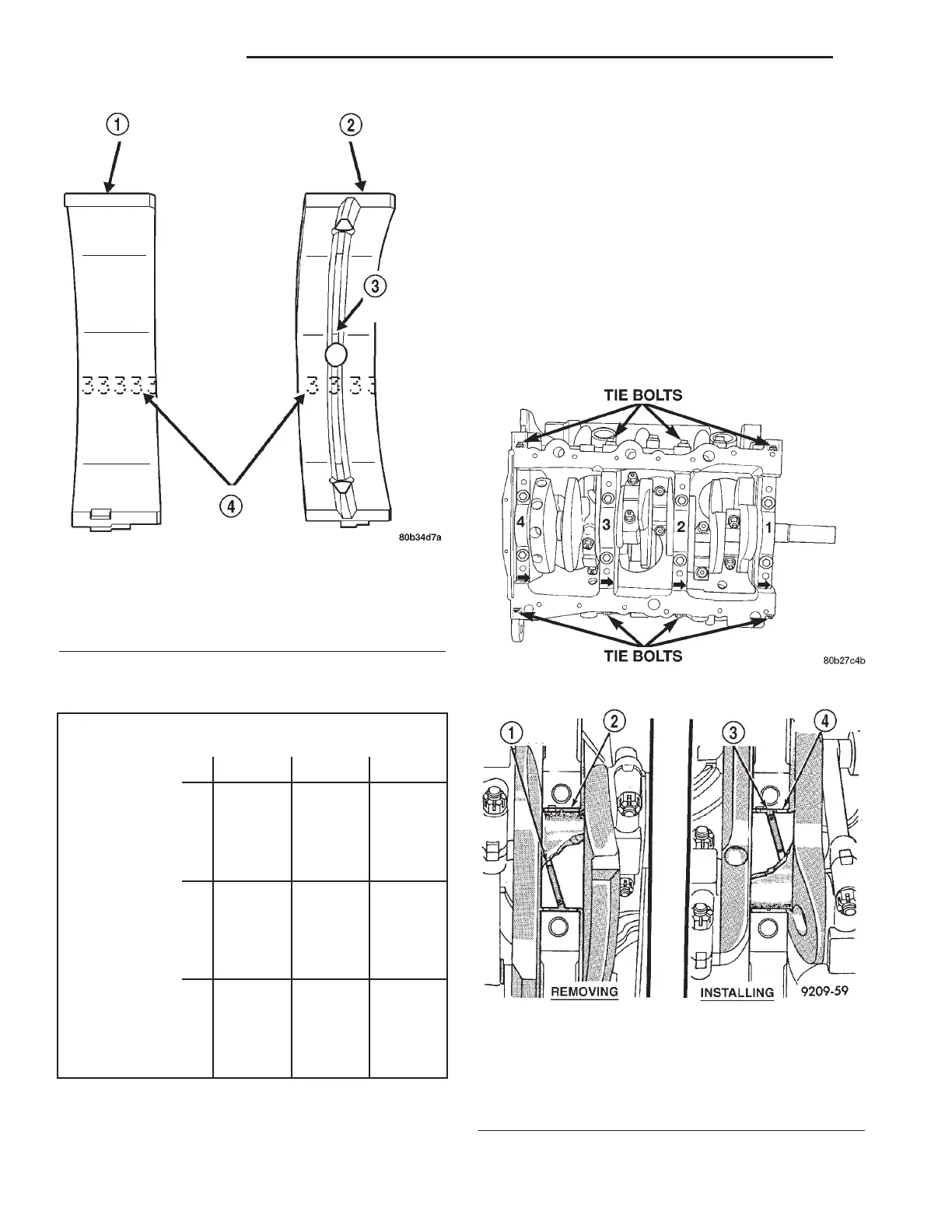

REMOVAL

Bearing caps are not interchangeable and are

marked to insure correct assembly (Fig. 68). Upper

and lower bearing halves are NOT interchangeable.

(1) Remove oil pan. (Refer to 9 - ENGINE/LUBRI-

CATION/OIL PAN - REMOVAL)

(2) Remove oil pick-up tube and windage tray.

(3) Identify bearing caps before removal (Fig. 68).

(4) Remove bearing caps one at a time. Remove

upper half of bearing by inserting Special Main Bear-

ing Tool C-3059 (Fig. 69) into the oil hole of crank-

shaft.

(5) Slowly rotate crankshaft clockwise, forcing out

upper half of bearing shell.

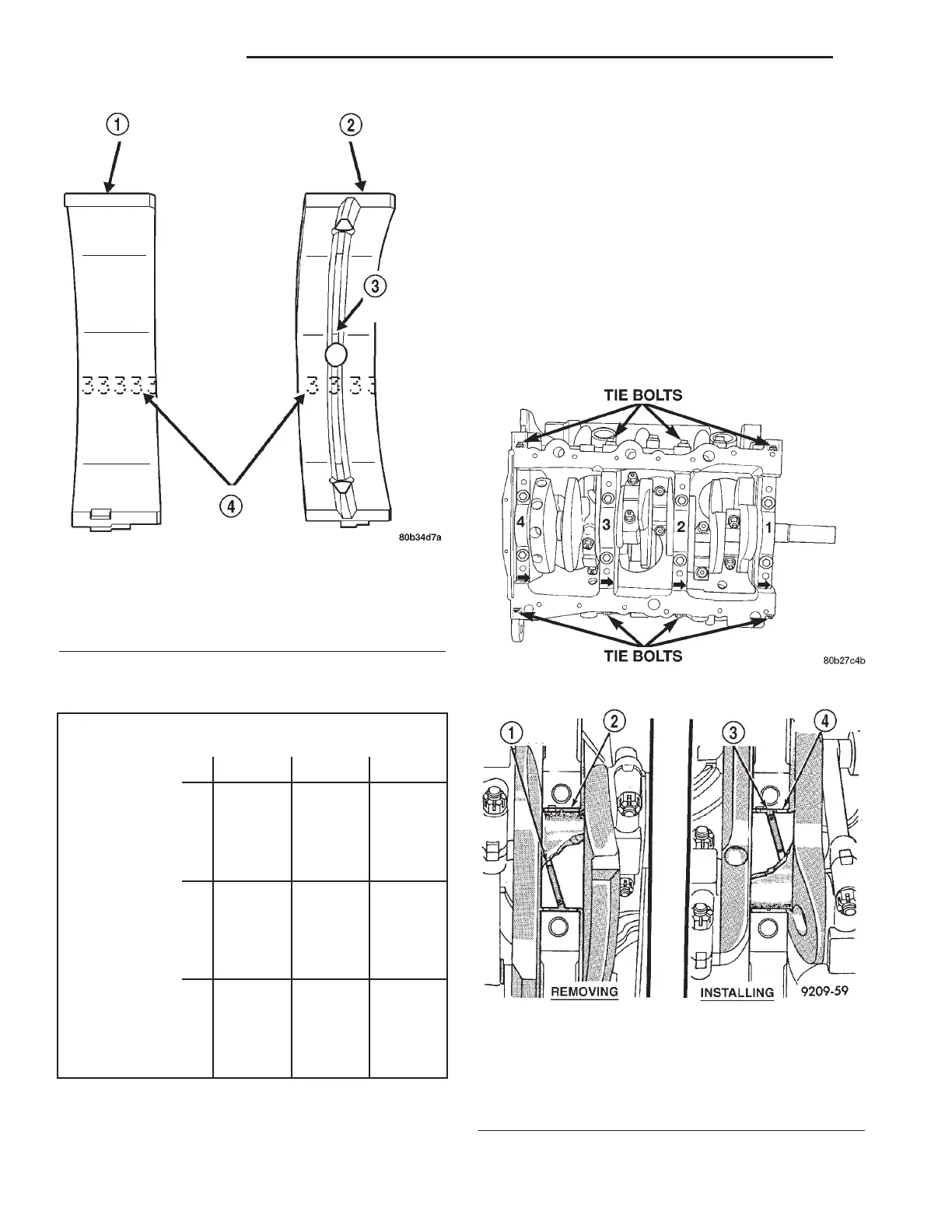

Fig. 67 Main Bearing Grade Marks

1 - LOWER MAIN BEARING

2 - UPPER MAIN BEARING

3 - OIL FEED HOLE AND GROOVE

4 - GRADE SELECTION INK MARKS

Fig. 68 Main Bearing Cap Identification

Fig. 69 Removing and Installing Upper Main Bearing

With Special Tool C- 3059

1 - SPECIAL TOOL C-3059

2 - BEARING

3 - SPECIAL TOOL C-3059

4 - BEARING

9 - 134 ENGINE 3.5L LH

CRANKSHAFT MAIN BEARINGS (Continued)

Loading...

Loading...