POSSIBLE NOISE SOURCES POSSIBLE NOISE MISDIAGNOSIS SOURCES

Spongy/soft/aerated lash adjusters. SRV valve axle chatter.

Missing lash adjuster swivel contact pads. Exhaust rocker arm-to-cylinder head cover contact.

Intake rocker-to-camshaft bearing journal contact. Piston pin bore fit.

Rocker arm bind-up. Timing drive hydraulic tensioner tick.

Intake rocker arm-to-spark plug tube contact. Accessory drive belt deterioration.

Excessive cam end play. Piston-to-bore clearance knock.

Broken valve spring. Crankshaft bearing noise.

Broken/loose camshaft sprocket bolt.

Incomplete cam lobe machining.

Cracked lash adjuster cartridge body.

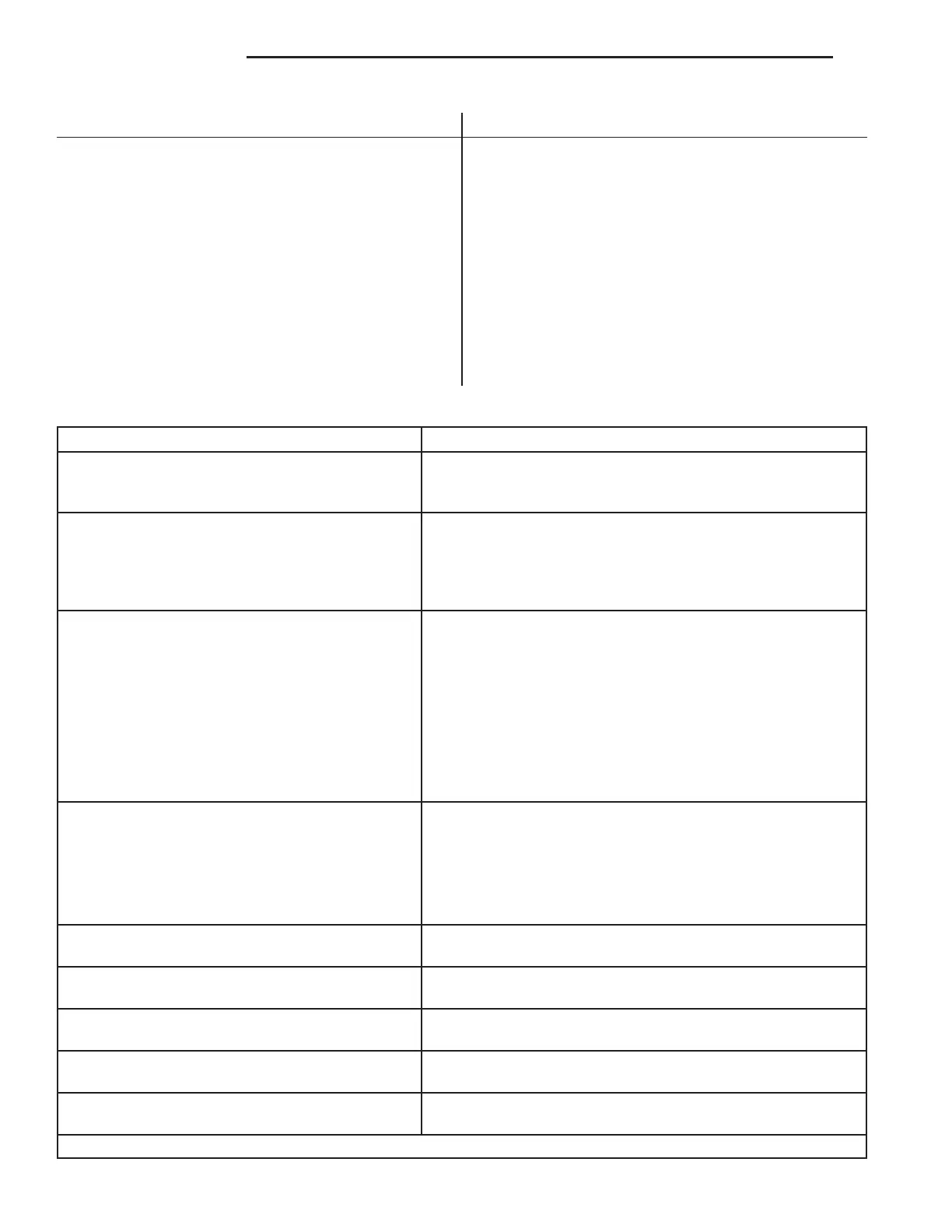

LASH ADJUSTER (TAPPET) NOISE CHART

POSSIBLE CAUSES CORRECTION

1. Engine oil level—too high or too low. This may

cause aerated oil to enter the adjusters and

cause them to be spongy.

1. Check and correct engine oil level.

2. Insufficient running time after rebuilding

cylinder head.

2. Low speed running of up to 1 hour may be required to fully

evacuate trapped air from the valve train system. During this

time, turn engine off and let set for a few minutes before

restarting. Repeat this several times after engine has

reached normal operating temperature.

3. Air trapped in lash adjuster (after 1 hour run

time).

3. See below:

(a) Check lash adjusters for sponginess while installed in

cylinder head. Depress part of rocker arm over adjuster.

Normal adjusters should feel very firm. Very spongy adjusters

can be bottomed out easily.

(b) Before proceeding, perform Lash Adjuster Bleeding

procedure.

(c) If lash adjuster(s) are still spongy, replace with new

adjuster/rocker arm assembly*.

4. Low oil pressure 4. See below:

(a) Check and correct engine oil level.

(b) Check engine oil pressure.

(c) Check for excessive bearing clearance and correct.

(d) Check for worn oil pump.

5. Oil passage to cylinder head(s) plugged with

debris.

5. Check cylinder head oil passages and cylinder head

gasket restrictor for blockage. Clean or replace as necessary.

6. Worn valve guide(s). 6. Ream guide(s) and replace valve(s) with oversize valves

and seal(s).

7. Air injested into oil due to broken or cracked oil

pump pickup tube.

7. Inspect pickup tube and replace as necessary.

8. Collapsed lash adjuster due to debris injestion. 8. Clean debris from engine and replace lash adjuster/rocker

assembly*.

9. Intake rocker arm roller clevis ear(s) contacting

camshaft bearing journal(s) on side.

9. Inspect camshaft end play and all valve train components

for wear. Replace as necessary.

*Lash adjusters are serviced with the rocker arms—do not disassemble.

9 - 120 ENGINE 3.5L LH

ROCKER ARM / ADJUSTER ASSEMBLY (Continued)

Loading...

Loading...