PERFORMANCE TEST PROCEDURE

Before performing the following procedure, (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMB-

ING - WARNING). Air temperature in test room and

in vehicle must be 21° C (70°F) minimum for this

test.

NOTE: When connecting the service equipment

coupling to the line fitting, verify that the valve of

the coupling is fully closed. This will reduce the

amount of effort required to make the connection.

(1) Connect a tachometer and manifold gauge set

or an A/C Charging/Recycling Station.

(2) Set controls:

MTC (Manual Temperature Control) System:

• A/C ON

• Panel Recirculation

• Temperature to full cold

• High blower

ATC (Automatic Temperature Control) System:

• Rotate blower knob to high position (full clock-

wise)

• Set temperature to the LO position

• Push panel mode button

• Push RECIRC (Recirculation) button (A/C and

RECIRC symbols should be lit)

NOTE: The word MANUAL should appear in the ATC

display, confirming that the system is set manually.

(3) Start engine and hold at 1000 rpm with A/C

clutch engaged.

(4) Engine should be warmed up with doors and

windows closed.

(5) Insert a thermometer in the left center A/C

outlet and operate the engine for five minutes. The

A/C clutch may cycle depending on ambient condi-

tions.

(6) With the A/C clutch engaged, compare the

discharge air temperature to the A/C Performance

Temperature table.

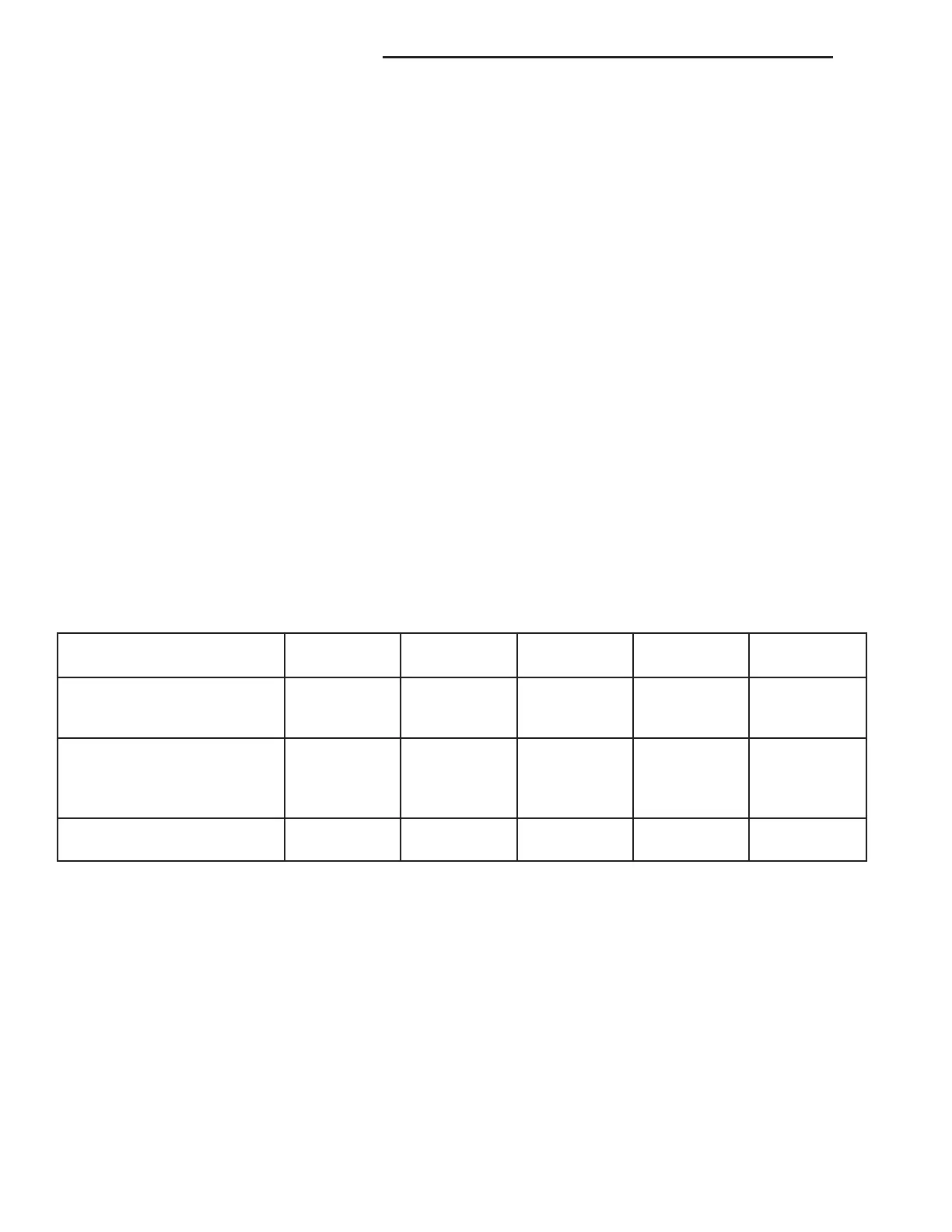

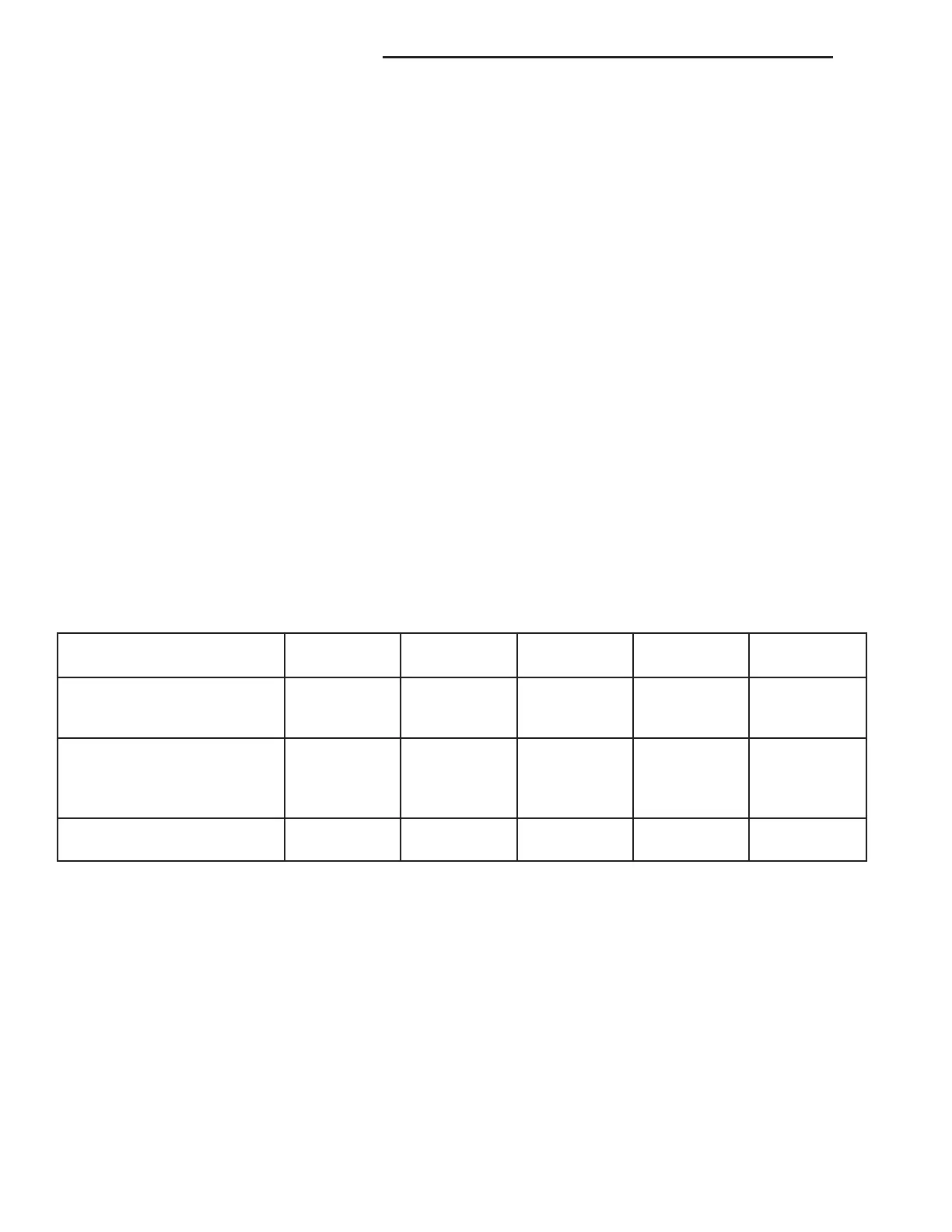

A/C PERFORMANCE TEMPERATURE AND PRESSURE

AMBIENT TEMPERATURE

21°C

(70°F)

26.5°C

(80°F)

32.5°C

(90°F)

37°C

(100°F)

43°C

(110°F)

MAXIMUM ALLOWABLE AIR

TEMPERATURE AT CENTER

LEFT PANEL OUTLET

6°C

(42°F)

7°C

(45°F)

10°C

(50°F)

12°C

(54°F)

15°C

(59°F)

COMPRESSOR

DISCHARGE PRESSURE

1379–1585

kPa

(200–230

psi)

1448–1723

kPa

(210–250

psi)

1654–1930

kPa

(240–280

psi)

1930–2206

kPa

(280–320

psi)

2206–2516

kPa

(320–365 psi)

COMPRESSOR SUCTION

PRESSURE

103–172 kPa

(15–25 psi)

139–208 kPa

(20–30 psi)

172–241 kPa

(25–35 psi)

208–276 kPa

(30–40 psi)

241–310 kPa

(35–45 psi)

DIAGNOSIS AND TESTING - HEATER

PERFORMANCE TEST

PRE-DIAGNOSTIC PREPARATIONS

Check the coolant level, drive belt tension, vacuum

line connections, electrical connections, radiator air

flow and fan operation. Start engine and allow to

warm up to normal temperature.

WARNING: DO NOT REMOVE RADIATOR CAP

WHEN ENGINE IS HOT, SEVERE PERSONAL

INJURY CAN RESULT.

If vehicle has been run recently, wait until engine

is cool before removing cap. Squeeze the radiator

hose to check temperature, and for pressure in the

system. If the hose is very firm, allow time to cool

down. Place a rag over the cap and turn it to the first

safety stop. Allow pressure to escape through the

overflow tube. When the system stabilizes, remove

the cap completely.

MAXIMUM HEATER OUTPUT: TEST AND ACTION

Engine coolant is provided to the heater system by

two 19 mm (3/4 inch inside diameter) heater hoses.

With engine idling at normal running temperature,

set the control to maximum heat, floor, and high

blower setting. Using a test thermometer, check the

air temperature coming from the floor outlets. Refer

to Temperature Reference Table.

24 - 2 HEATING & AIR CONDITIONING LH

HEATING & AIR CONDITIONING (Continued)

Loading...

Loading...