C8 Maintenance 8. Joint #4

344 C Series Maintenance Manual Rev.2

8. Joint #4

WARNING

■

Do not connect or disconnect the motor connectors while the power to the robot

system is turned ON. Connecting or disconnecting the motor connectors

with

the power ON is extremely hazardous and may result

in serious bodily injury as

ve abnormally, and also may result in electric shock

and/or malfunction of the robot system.

To shut off power to the robot system, disconnect the power plug from the power

source. Be sure to connect the AC power cable to a power receptacle.

DO NOT connect it directly to a factory power source.

performing any replacement procedure, turn OFF the Controller and

and then disconnect the power plug from the power source.

Performing any replacement procedure with the power ON is extremely hazardous

and may result in

electric shock and/or malfunction of the robot system.

CAUTION

■

Be careful not to apply excessive shock to the motor shaft during replacement.

The shock may shorten the life of the motors and encoder and/or damage them.

Never disassemble the motor and the encoder.

Disassembled motor and

encoder will cause a positional gap and cannot be used again.

After parts have been replaced (motors, reduction gear units, timing belts, etc.), the

Manipulator cannot perform positioning properly because a gap exists between the origin

stored in each motor encoder and its corresponding origin stored in the Controller.

Therefore, it is necessary to match these origins after replacing the parts.

The process of aligning the two origins is called “Calibration”.

Refer to C8 Maintenance 16. Calibration and perform the calibration after the parts

replacement.

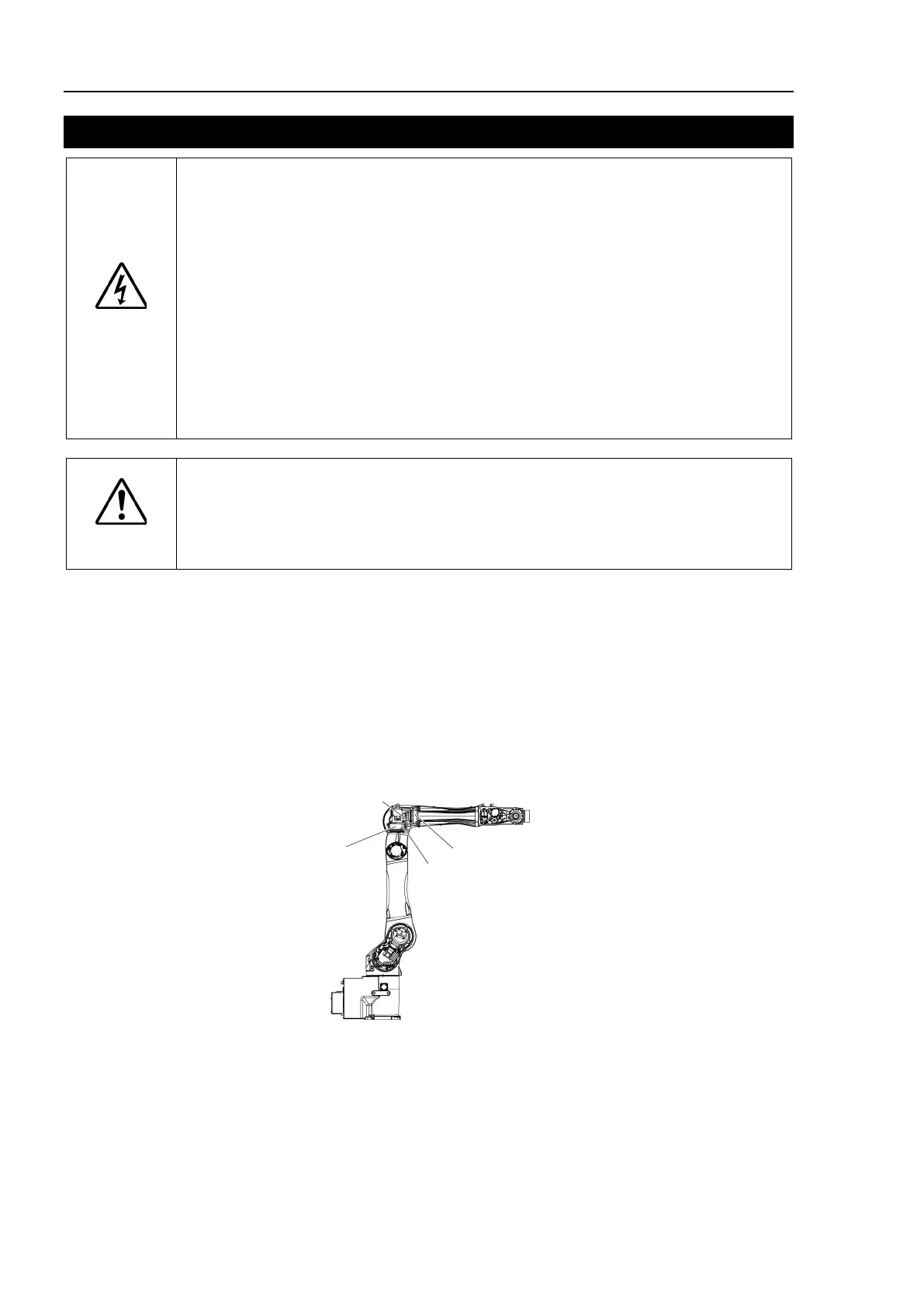

Joint #4 Electromagnetic brake

Joint #4 Motor

Joint #4 Reduction gear unit

Joint #4 Timing belt

(Figure: C8-A1401* (C8XL))

Loading...

Loading...