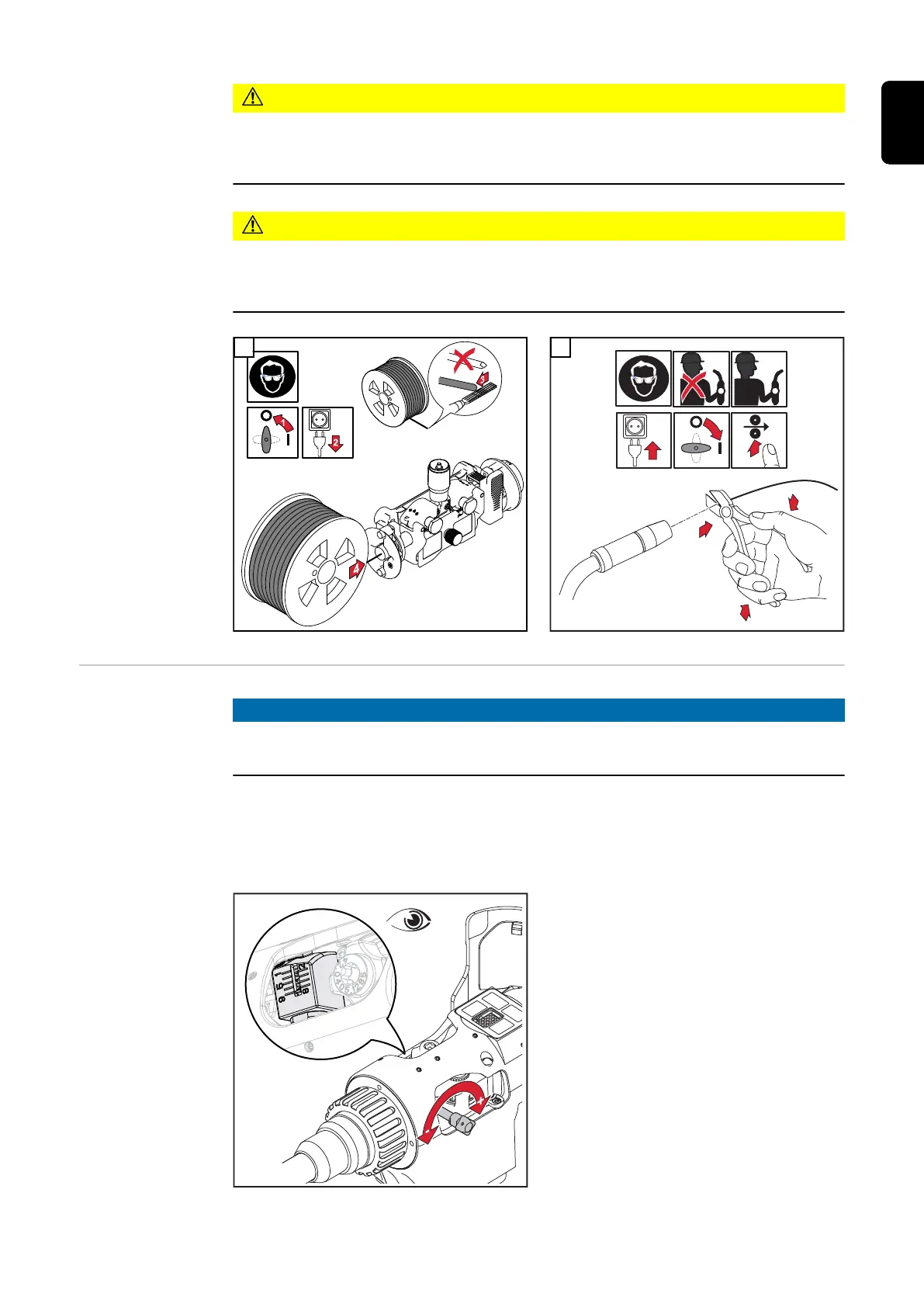

CAUTION!

Risk of injury due to springiness of spooled wire electrode.

▶

When inserting the wire electrode into the 4-roller drive, hold the end of the

wire electrode firmly to avoid injuries caused by the wire springing back.

CAUTION!

Risk of injury from moving or rotating parts in the welding system.

▶

Ensure that all covers are closed and that all parts are fitted properly and re-

main in place during operation.

1

2

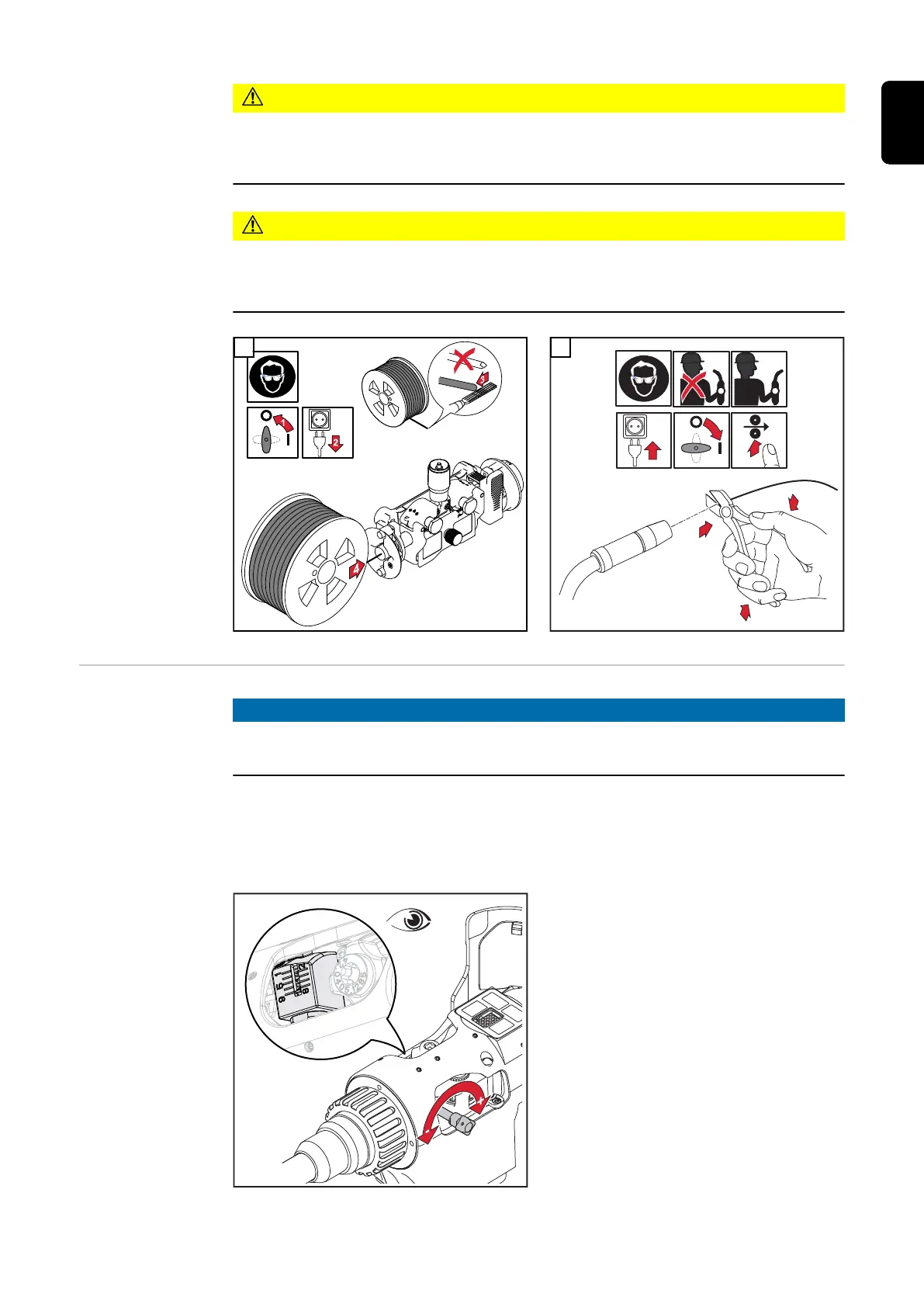

Setting the con-

tact pressure for

the WF 25i

Robacta Drive

NOTE!

Set the contact pressure in such a way that the wire electrode is not deformed

but nevertheless ensures proper wirefeeding.

IMPORTANT! In the event of a large change in contact pressure, a system calib-

ration must be carried out.

How to perform the system calibration is explained in the power source Operat-

ing Instructions.

Contact pressure standard values for

steel rollers:

Al,

AlSi

1 - 2

AlMg 2 - 4

FCW 3 - 5

CuSi 5 - 7

Steel 6 - 8

CrNi 6 - 8

153

EN

Loading...

Loading...