Robot welding torch

Safety

CAUTION!

Risk of burns from hot torch body, hot torch body coupling and other hot weld-

ing torch components.

Before starting work on the torch body, the torch body coupling and all other

welding torch components:

▶

Allow the torch body, torch body coupling and all other welding torch com-

ponents to cool down to room temperature (+25 °C, +77 °F)

▶

Wear electrically insulated and heat protective gloves

▶

Use a suitable tool

General The following torch bodies are recommended for the CMT process:

-

MTB 250i / 320i / 400i / 500i / 700i: 22–36°

-

MTB 330i: 22°

The following maximum angles are permitted during the CMT process:

-

MTB 250i / 320i / 400i / 500i / 700i: 45°

-

MTB 330i: 36°

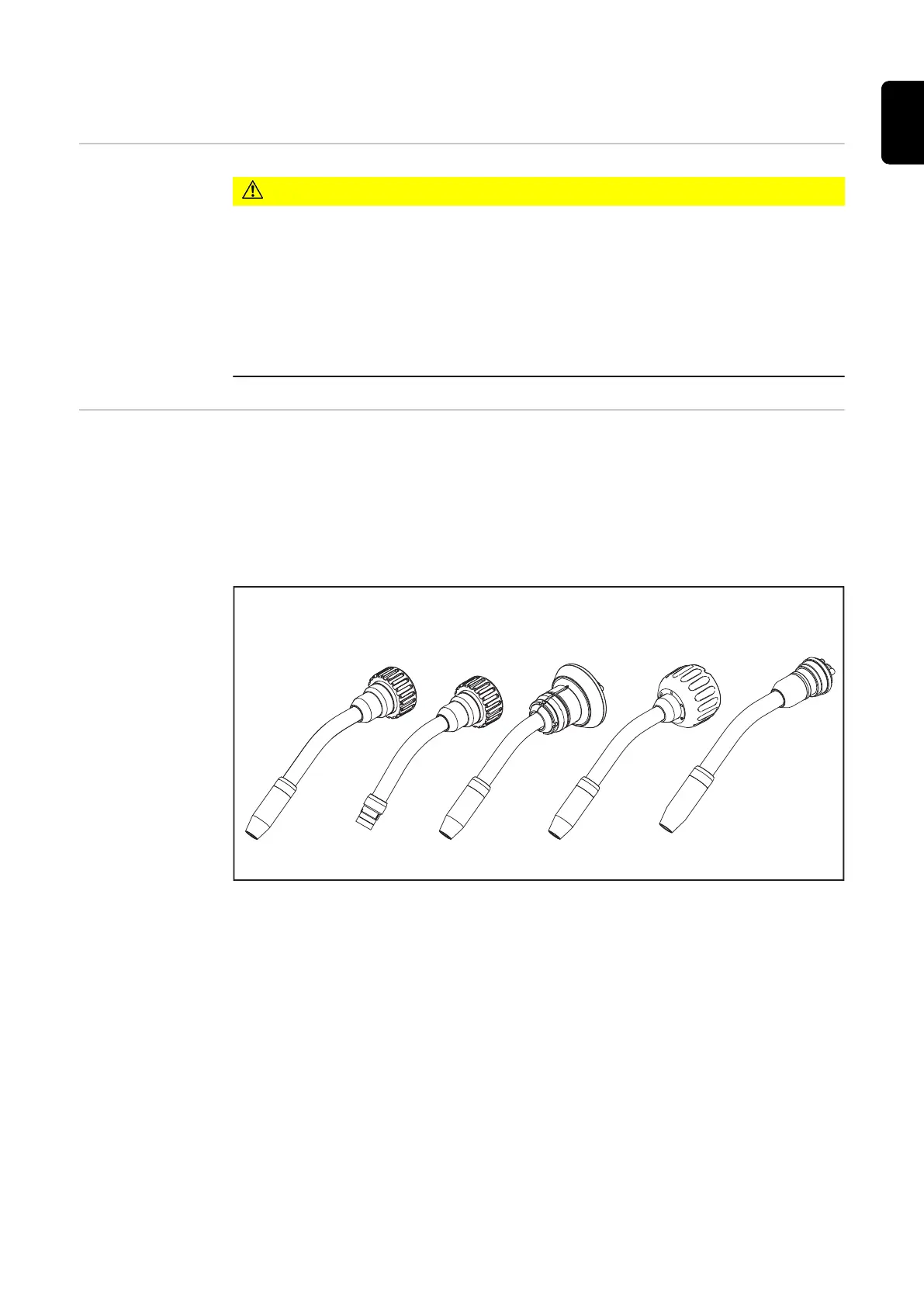

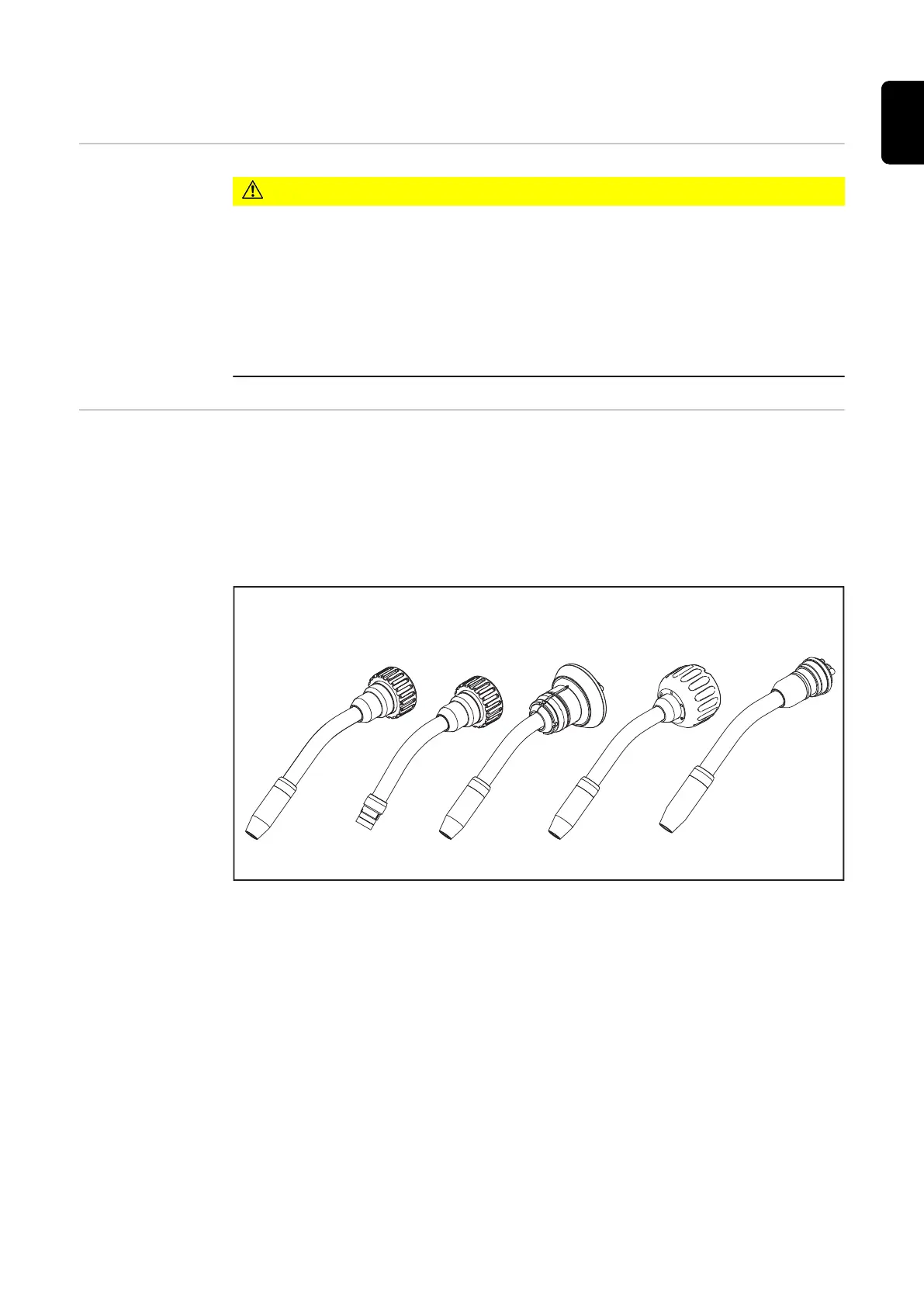

Standard OVT TXi TXM OPT CAM*

*Optional (no torch body)

The robot welding torch transmits the arc power to the workpiece. The gas-

cooled or water-cooled TPS /i welding torch is designed for use with the Crash-

Box /i.

The torch body has an integrated lead for gas nozzle touch sensing.

Standard:

With wearing parts, without contact tip

OVT:

Without wearing parts

TXi:

Automatic torch body changeover

TXM:

Manual torch body changeover

55

EN

Loading...

Loading...