When repeatedly connecting and disconnecting the coolant hoses on the torch

hosepack, grease the O-rings regularly.

Unless a special grease is specified for the O-rings, use the O-ring grease from

Fronius with item number 40,0009,0044.

Whenever the

welding torch or

torch hosepack

is changed

Whenever the welding torch or torch hosepack is changed, ensure that the coup-

ling point is clean and dry. Remove any coolant that has escaped from the coup-

ling point.

Changing the

torch hosepack,

changing the in-

terconnecting

hosepack

If a robot wirefeeder or a media splitter is mounted in the third robot axis, take

the following into account when changing the torch hosepack or interconnecting

hosepack:

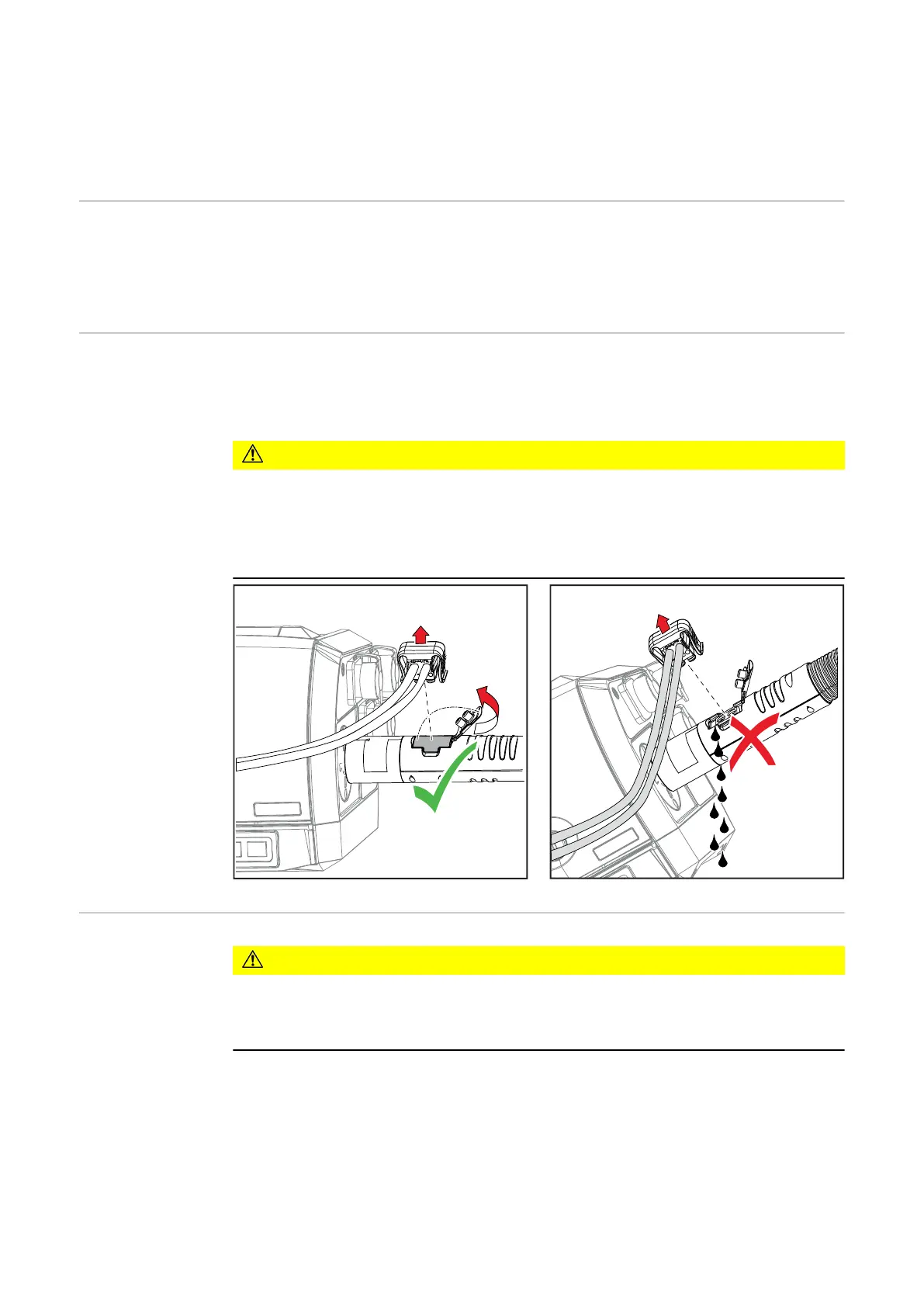

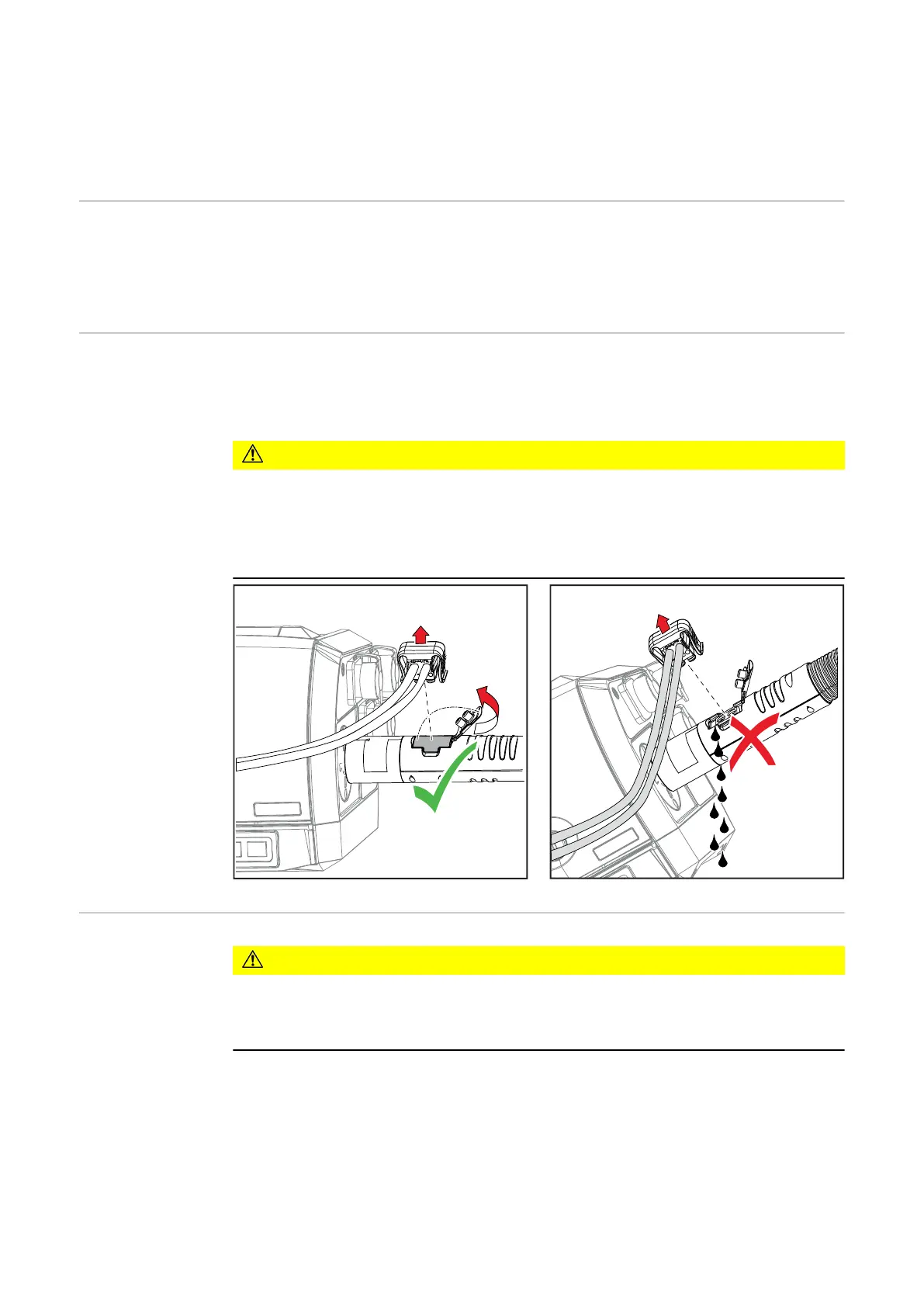

CAUTION!

Risk of damage to the robot wirefeeder or media splitter from escaping coolant.

▶

After disconnecting the coolant hoses on the torch hosepack, close the

coolant connections with the cover provided immediately.

▶

Position the robot in such a way that escaping coolant cannot flow back into

the robot wirefeeder or the media splitter.

Every 6 months

CAUTION!

Danger from compressed air at close range.

Electronic components may be damaged.

▶

Do not bring the air nozzle too close to electronic components.

-

Open covers, remove device side panels and clean inside of device with dry

reduced compressed air. After cleaning, restore device to its original state.

164

Loading...

Loading...