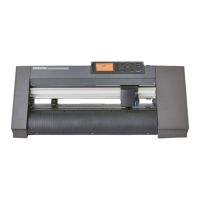

Why does GRAPHTEC CE7000-130AP media travel tilted?

- CColton CampbellSep 1, 2025

If the media travels tilted in your Graphtec Plotter, it could be due to several reasons. First, ensure that the media is loaded straight. If it's slipping, perform pre-feed to make an impression and reduce slippage. Also, verify that the hold-down force of the push roller is appropriate for the media being used; adjust accordingly.