WR1000-UM-251–01–9380 6 – 3

6. INSPECTION AND CHECK PROCEDURES

6.2 Inspection and Check Methods

6.2.1 Insulation Resistance

Use a megaohm meter (an insulation resistance gauge) to check that the insulation resistance between the

following terminals are equal to or higher than the rated values.

(1) Between the AC input and GND terminals:

Using a megaohm meterr with an output capacity of 1000 VDC, check that the measured insulation

resistance is 100 MΩ or more.

(2) Between the signal input and GND terminals:

Using a megaohm meter with an output capacity of 500 VDC, check that the measured insulation resis-

tance is 100 MΩ or more.

6.2.2 Dielectric Strength

Using a dielectric strength tester to apply an experimental voltage between the following terminals, check that

the current equals or is lower than the rated value within the stipulated time.

(1) Between the AC input and GND terminals:

After applying an experimental voltage of 2.3 kVAC rms for no more than two seconds, check that the

value of the current sustained for two seconds is:

• 15 mA or less for an eight-channel model; or

• 20 mA or less for a 16-channel model.

(2) Between the signal input and GND terminals:

After applying an experimental voltage of 2.3 kVAC rms for no more than two seconds, check that the

value of the current sustained for two seconds is 2 mA or less.

6.2.3 Voltage Precision

Supply the reference voltage determined for each measurement range to each installed amp, then check the

voltage precision.

Preparation

• Use a voltage generator that can output up to 500 VDC (using four-digit settings).

• Mutually connect the ground terminals of the voltage generator and WR1000 prior to initiating measurement.

Setting Procedure

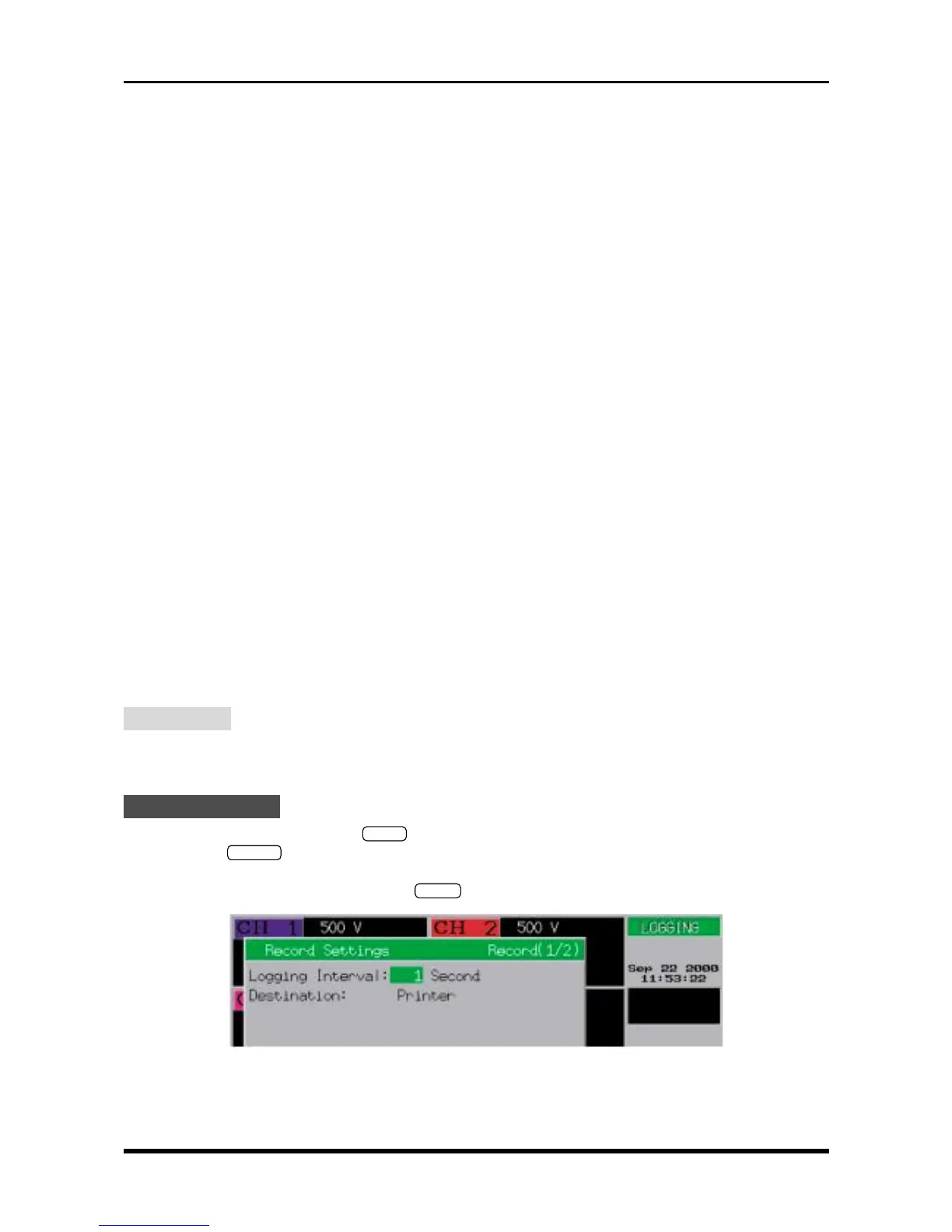

(1) Press the main control panel’s

MODE

key to select LOGGING as the measurement mode.

(2) Press the

RECORD

key on the Conditions panel to respectively display the Record Settings and Format

Settings windows. To enter the following settings at each window, use the arrow keys to move the cursor

to the desired parameter, then use the

ENTER

key and arrow keys to enter the desired settings.

Fig. 6-2-1. Record Settings window

Logging Interval : 1 Second

Destination : Printer

Loading...

Loading...