SCANNER SAFETY AND LOCAL CONTROLS

Table. 2. Compressed Air and Coolant Precautions

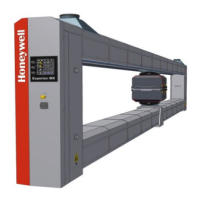

Red hoses, compressed air (See

Fig 12)

Energized air lines can cause

projectile motion and hose-whip that

is dangerous to body and eyes.

Ensure that compressed air to the scanner

is isolated and de-energized; wear eye

protection.

Green hoses, pressurized water

/ glycol coolant mixture

(See Fig 12)

Pressurized or full coolant lines can

lead to contact with skin or eyes, as

well as spill potential

Ensure that coolant lines are blocked off or

drained, and chiller pump is disabled. Wear

eye protection. Review mill procedures for

handling fluid spills prior to work.

Accidental removal of black

flow meter knob

(See Fig 12)

Flow meter adjustment knob will pop

off unexpectedly if turned opened too

far; a strong stream of coolant will

shoot toward the upper torso and

face

Use care when turning adjustment dial to

gain more flow. Stop turning knob when it is

seen that the flow stops increasing. About

two extra turns are required to remove knob

from full open state. Keep a firm grip on

knob. Wear eye protection.

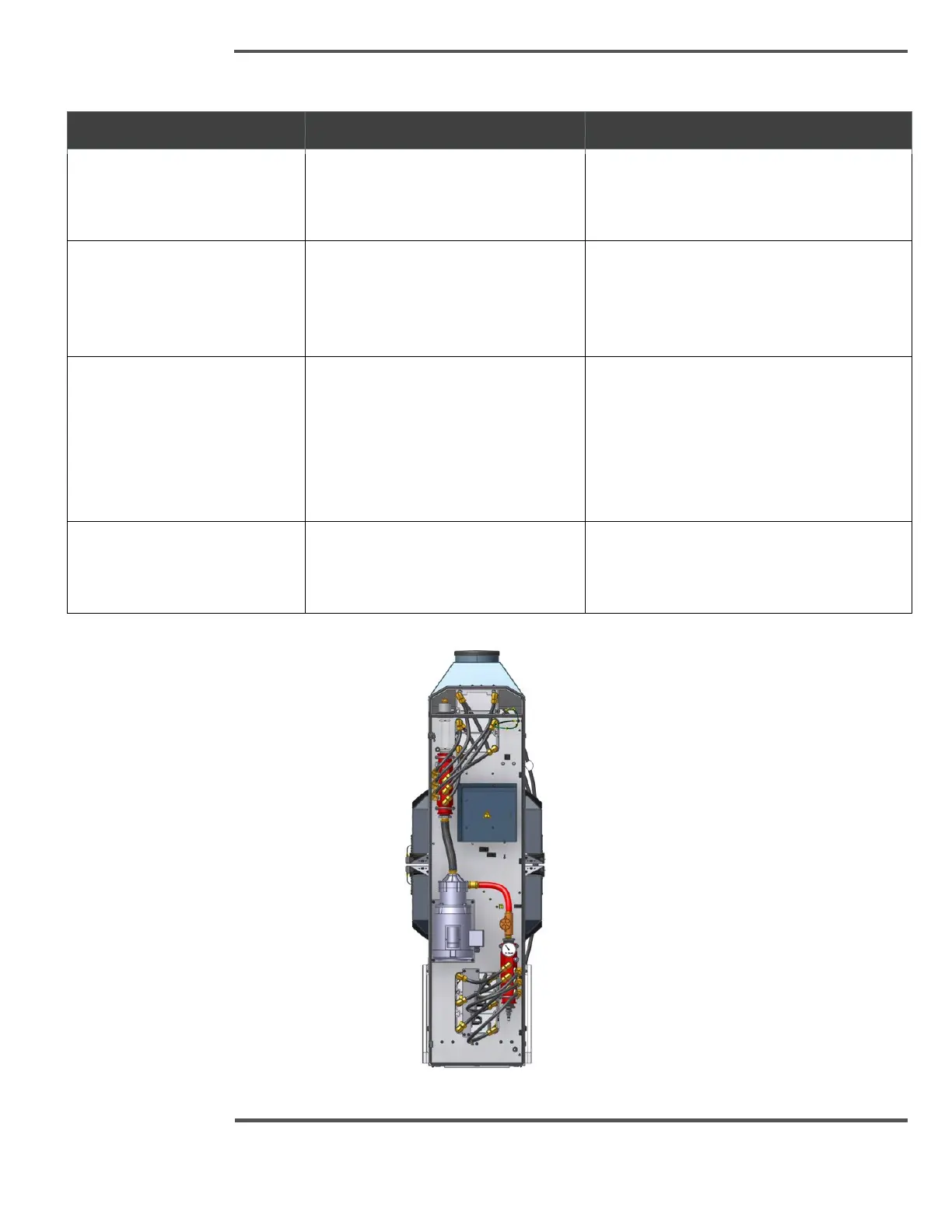

TES pressurized water / glycol

coolant hoses, both ends of

beam (See Fig 13)

Working on coolant lines, full or

pressurized, can lead to contact with

skin or eyes, as well as spill potential

Disable TES pump. If required, partially or

fully drain TES below level of work.

Fig. 14. TES Coolant Hoses

Loading...

Loading...