3 Getting Started

3.1 About Experion MX Quality Control System

The Experion MX Quality Control System (QCS) is designed and engineered to:

• Accurately measure and collect process information

• Use the collected process information to control the process

• Display the information clearly to operators and process engineers

• Provide not only process information but also historical trending, statistical

analysis, and printed reports for better understanding and improved process

management.

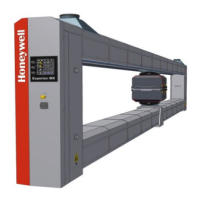

3.2 System Overview

A typical Experion MX system contains the following components:

• One or more scanners housing a number of sensors. Sensors may include:

• Basis weight

• Moisture

• Caliper

• Ash

• Color

• Coat Weight

• Gloss

• An Experion MX server computer

• Operator station(s). For small systems, the Experion MX server may also act as an

Operator station

• An interface to an Input/Output (I/O) subsystem such as a distributed control

system (DCS) or programmable logic controller (PLC). I/O is required if the system

is controlling process loops such as stock flow, steam pressure, dye flows

• Cross Direction (CD) control actuator systems for profile control

• An interface to a mill wide information system for data collection or reporting

• One or more printers

• Quality OptiMISER (data historian)

Loading...

Loading...