How the Plasma Power Supply Operates

158 810430 Troubleshooting Guide Powermax65/85/105 SYNC

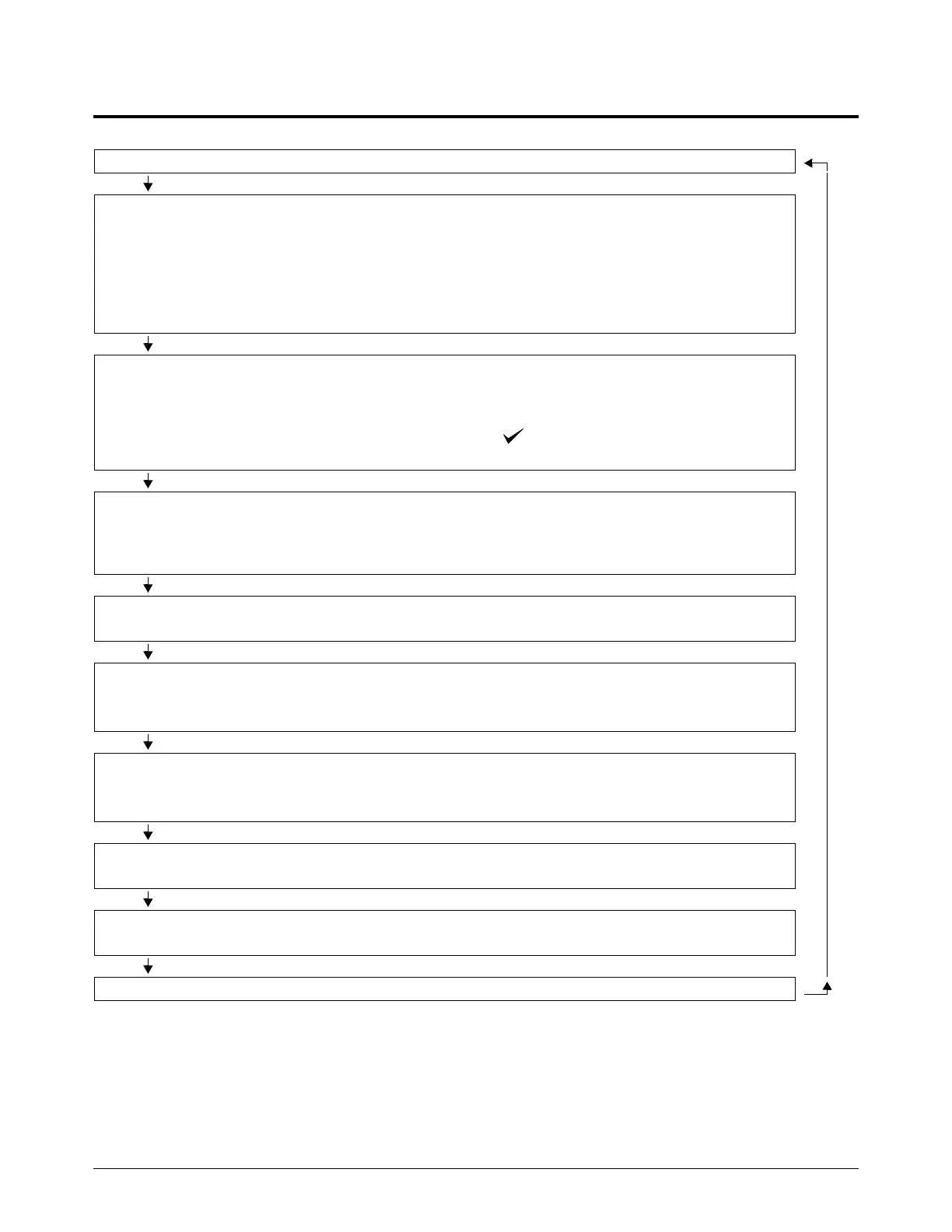

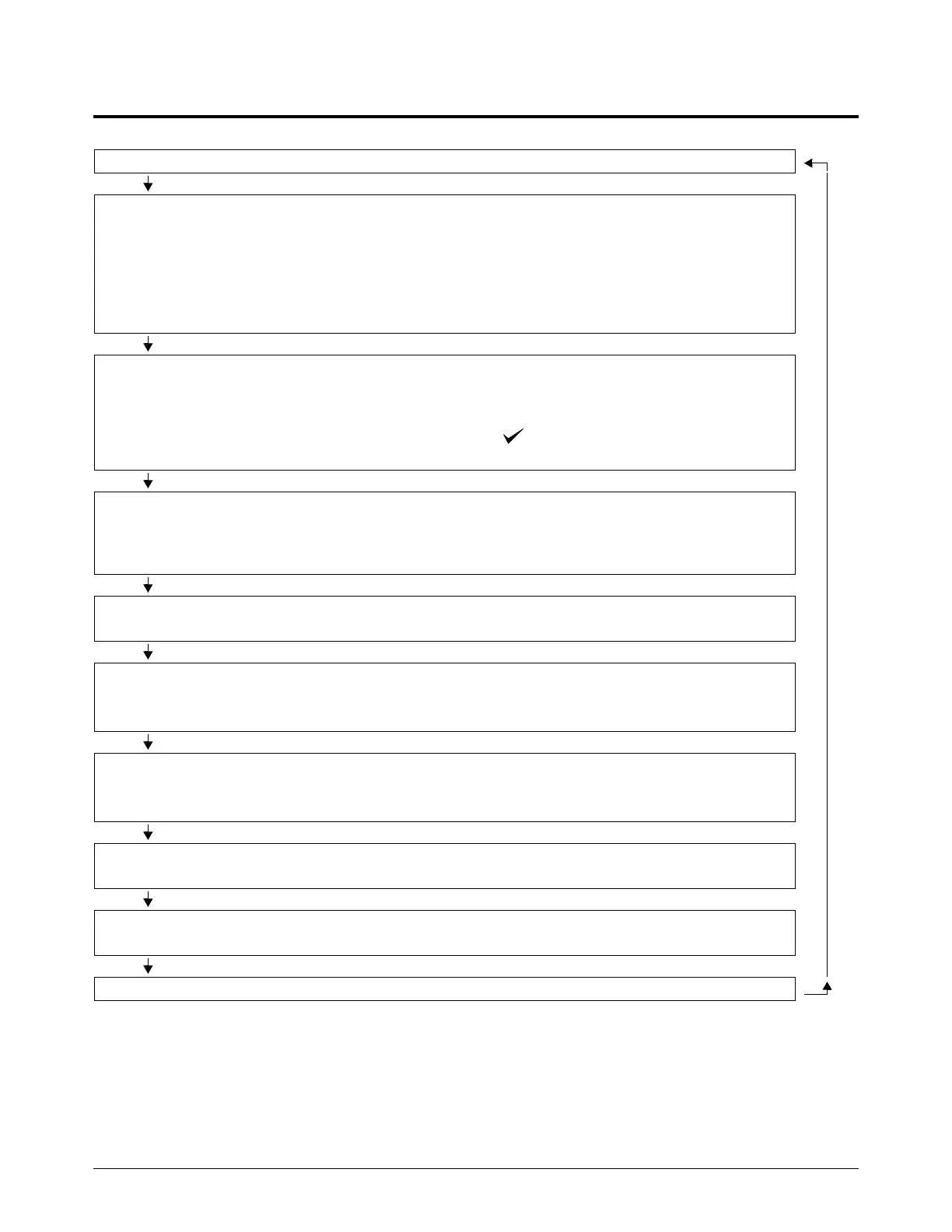

Sequence of operation

•Power OFF(O)

• Connect the gas supply to the gas fitting on the plasma power supply.

• Connect the work lead to the plasma power supply and workpiece.

• Connect the torch to the plasma power supply.

• Connect the plasma power supply to the power source.

• Make sure that incoming power is ON at the power source (for example, a line-disconnect box).

• Set the ON/OFF power switch to ON (I).

• The green power ON LED illuminates. The system is ready for operation.

• Set the torch-disable switch to the yellow lock (X) position.

• Install a cartridge on the torch.

• Set the torch-disable switch to the green “ready to fire” ( ) position.

• Make sure the yellow fault LED does not show on the front panel. Refer to page 39.

• The operating mode and the output current (A) automatically adjust to align with the cartridge

installed on the torch.

• The gas pressure automatically adjusts for optimal cutting to align with the system settings and the

torch and cartridge that are connected to the plasma power supply.

• Position the torch over the workpiece.

• Pull the plasma start trigger on the hand torch, or send a start signal to the machine torch.

• The gas solenoid valve opens.

• The gas flow starts.

• The plasma cutting arc starts.

• Pull the torch lightly across the workpiece to make a cut.

• The workpiece falls off after the cut.

• Release the plasma start trigger on the hand torch or the remote start switch for the machine torch.

• The plasma arc extinguishes.

• Gas postflow continues to decrease the temperature of the cartridge.

• The gas solenoid valve closes.

• The gas flow stops.

• Set the ON/OFF power switch to OFF (O).

Loading...

Loading...