Do System Tests to Identify Defective Components

11 8 810430 Troubleshooting Guide Powermax65/85/105 SYNC

Examine the solenoid valve sensor and power PCB sensor input

1. Set the power switch to OFF (O).

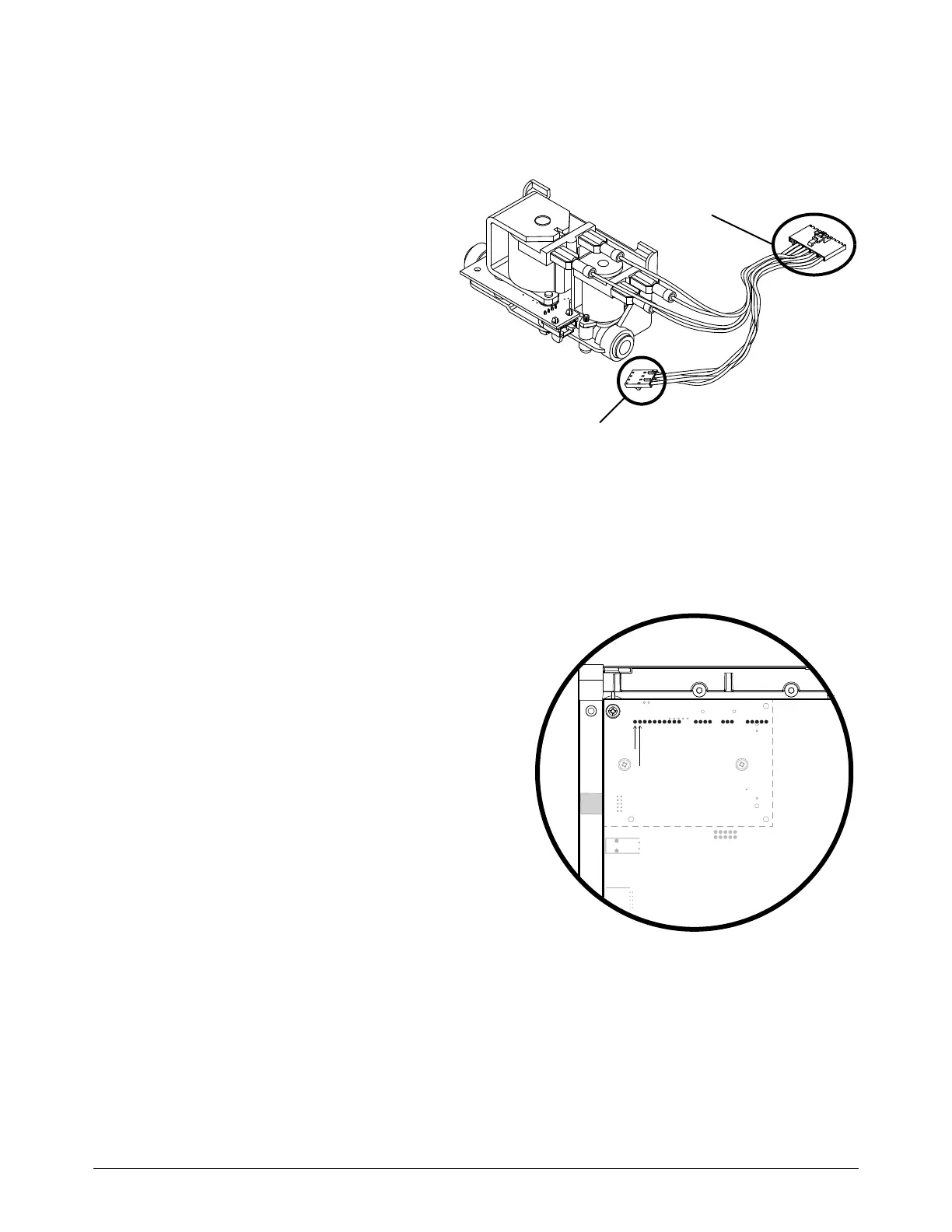

2. Disconnect the solenoid valve from

J4 or J6 on the power PCB.

3. Disconnect the J1 connector from

the solenoid valve PCB.

4. Are any of the pins on the connectors

or on the solenoid valve PCB

damaged?

If yes, replace the solenoid valve.

If no, continue with the next step.

5. Reconnect the valve to J4 or J6 on

the power PCB.

6. Reconnect J1 to the solenoid valve PCB.

7. Disconnect the gas supply.

8. Set the power switch set to ON (I).

9. Do a check of the output signal from the

solenoid valve pressure sensor. If the

sensor is operating correctly, the output

signal is approximately 0.2 VDC at 0 bar

(0 psi). Measure the voltage between

pin 1 and pin 2 on J4 or J6. Is the voltage

0.18 VDC – 0.22 VDC, but you continue

to get the 2-11-n fault code?

If yes, continue with the next step. The

solenoid valve pressure sensor is

operating correctly. The DSP PCB is

not reading the pressure signal

correctly, or the power PCB is not

sending the pressure signal to the

DSP PCB.

If no, replace the solenoid valve.

R

Loading...

Loading...