Do System Tests to Identify Defective Components

98 810430 Troubleshooting Guide Powermax65/85/105 SYNC

Test 6 – Torch stuck open (TSO) or torch stuck closed (TSC)

Use this test when you get 0-30-n faults during postflow and the Hypertherm cartridge is in good

condition and is installed correctly.

Examine the torch

1. Do a gas test for 2 minutes. Refer to page 26.

2. Monitor the gas pressure while the gas is flowing. If the pressure decreases gradually, look for

the following conditions that can cause the pressure to decrease:

Does the torch lead have any kinks?

Are there cable ties around the torch lead that are too tight?

Is there heavy equipment putting too much weight on part of the torch lead?

Are there signs of damage to the torch lead that can cause gas pressure leaks?

3. Connect a different torch to the plasma power supply that is known to operate correctly. Does

the 0-30-n fault go away?

If yes, continue with the next step.

If no, continue with Examine the plasma power supply on page 99.

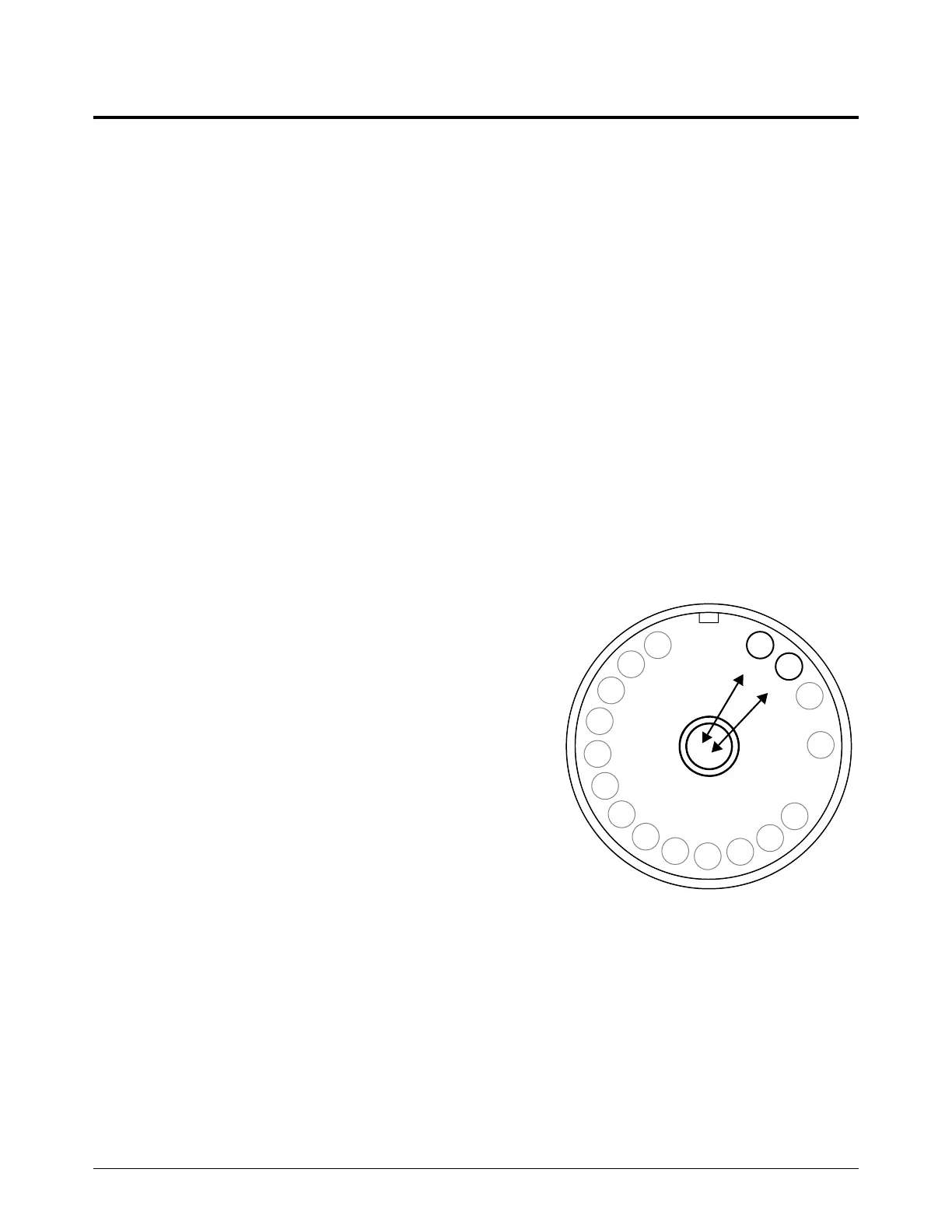

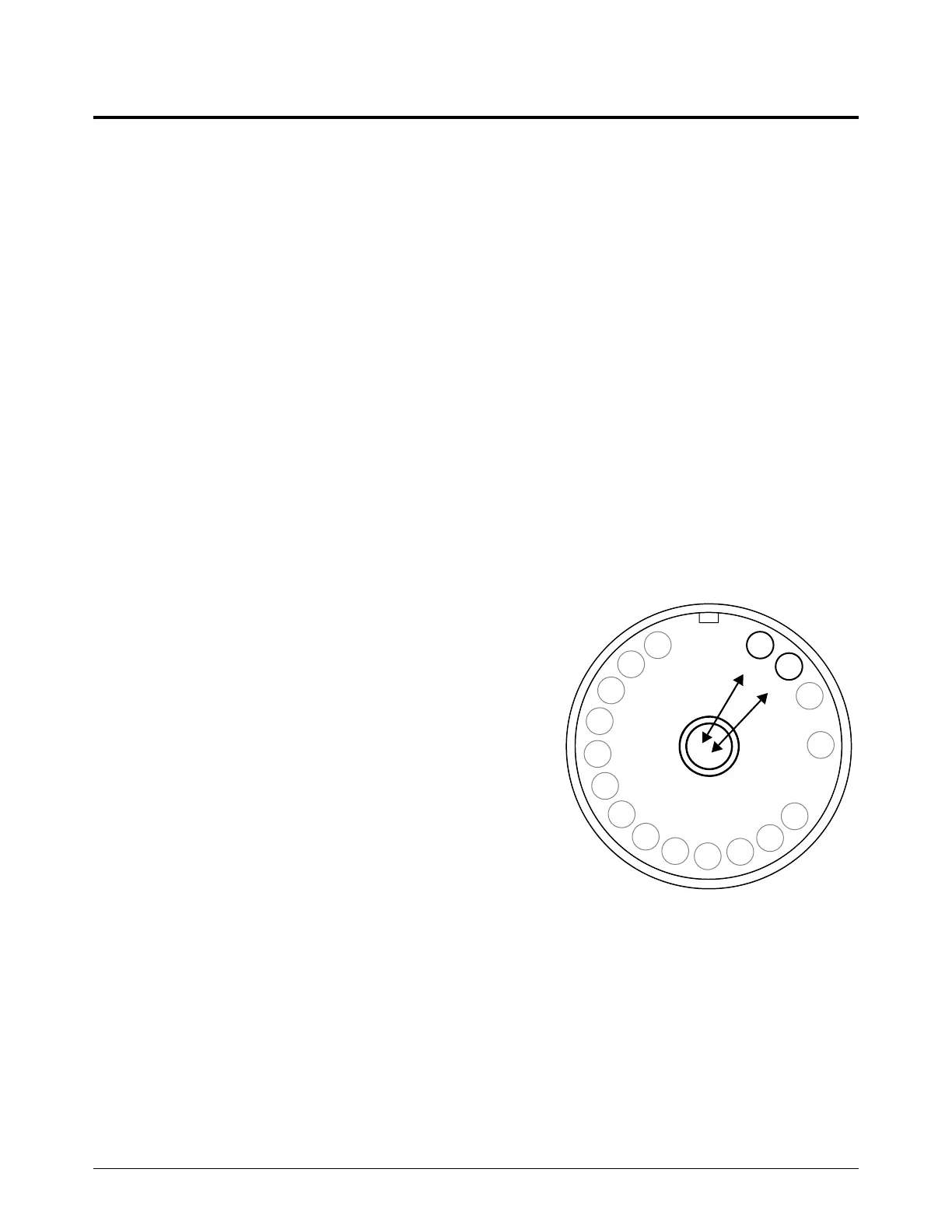

4. Do a check for continuity on the original torch,

as follows:

a. Make sure that a cartridge is installed on

the torch and that the torch is not

connected to the plasma power supply.

b. Do a check for continuity between pin 1 in

the torch connector and the brass in the

center of the connector.

c. Do a check for continuity between pin 2 in

the torch connector and the brass in the

center of the connector.

5. Is there continuity on both pins?

If yes, the problem can be with the plasma

power supply, not the torch. Continue with

Examine the plasma power supply on page 99.

If no, replace the torch lead.

BLK

BLK

1

2

3

4

5

BLU

6

VIO

7

ORG

8

BLK

9

BRN

10

GRY

11

YEL

12

WHT

13

RED

14

15

16

17

Loading...

Loading...