Maintenance

XPR300 Instruction Manual 809480 257

f. Leave the coolant return hose (red band) disconnected from the rear of the plasma power

supply.

g. Put a container under the pump plug.

h. Remove the plug and coolant pump screen and set them aside.

i. Remove the coolant supply hose (green band) from the rear of the

plasma power supply.

j. Attach compressed air (no more than 3.45 bar/50 psi) to the coolant

supply hose fitting on the rear of the plasma power supply where the

coolant supply hose (green band) was previously connected.

k. For no more than 30 seconds, use the compressed air to blow all of

the coolant into the container.

l. Leave the coolant supply hose (green band) disconnected.

System components need the coolant to lubricate rotating surfaces. If

air flows through the cutting system for longer than 30 seconds, it can

eliminate the coolant necessary for lubrication.

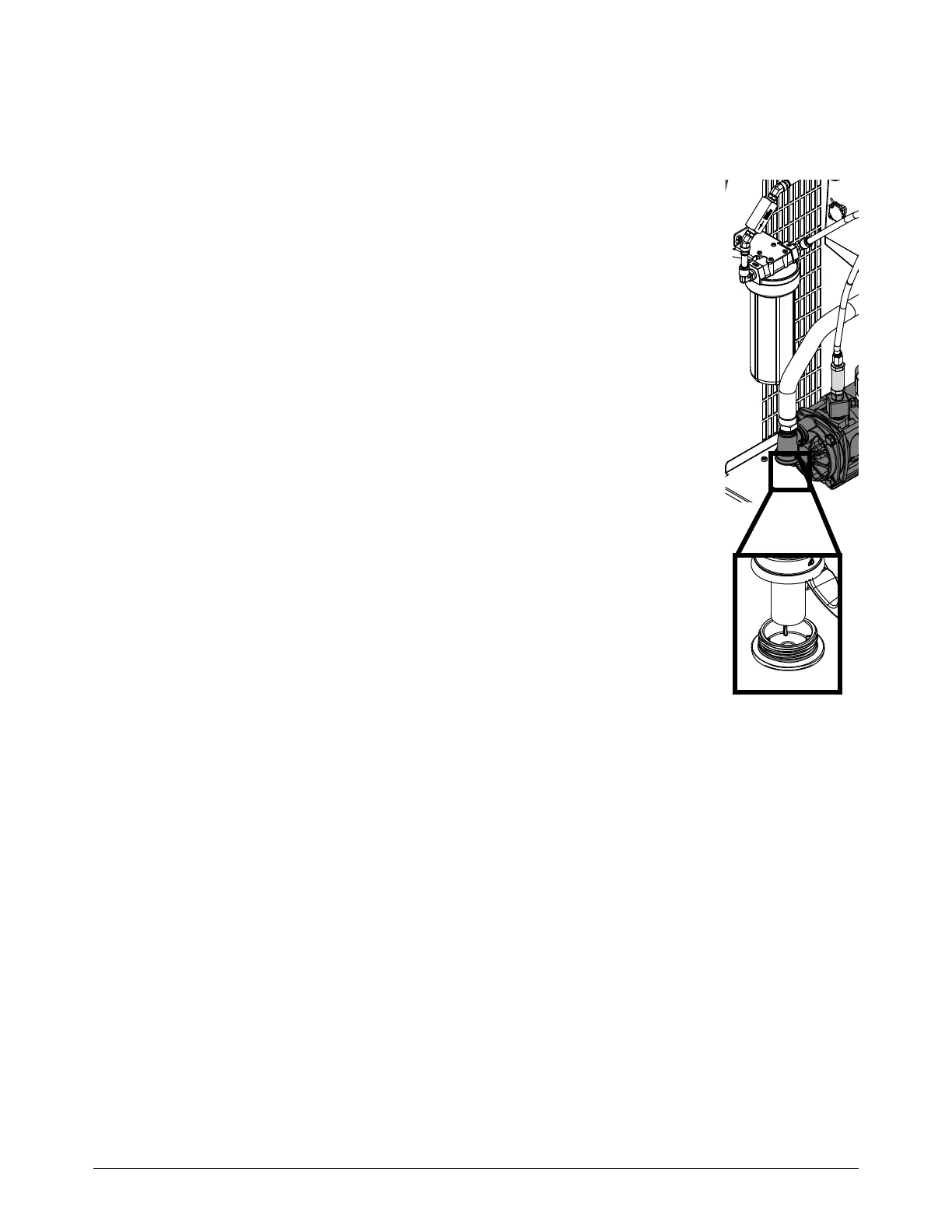

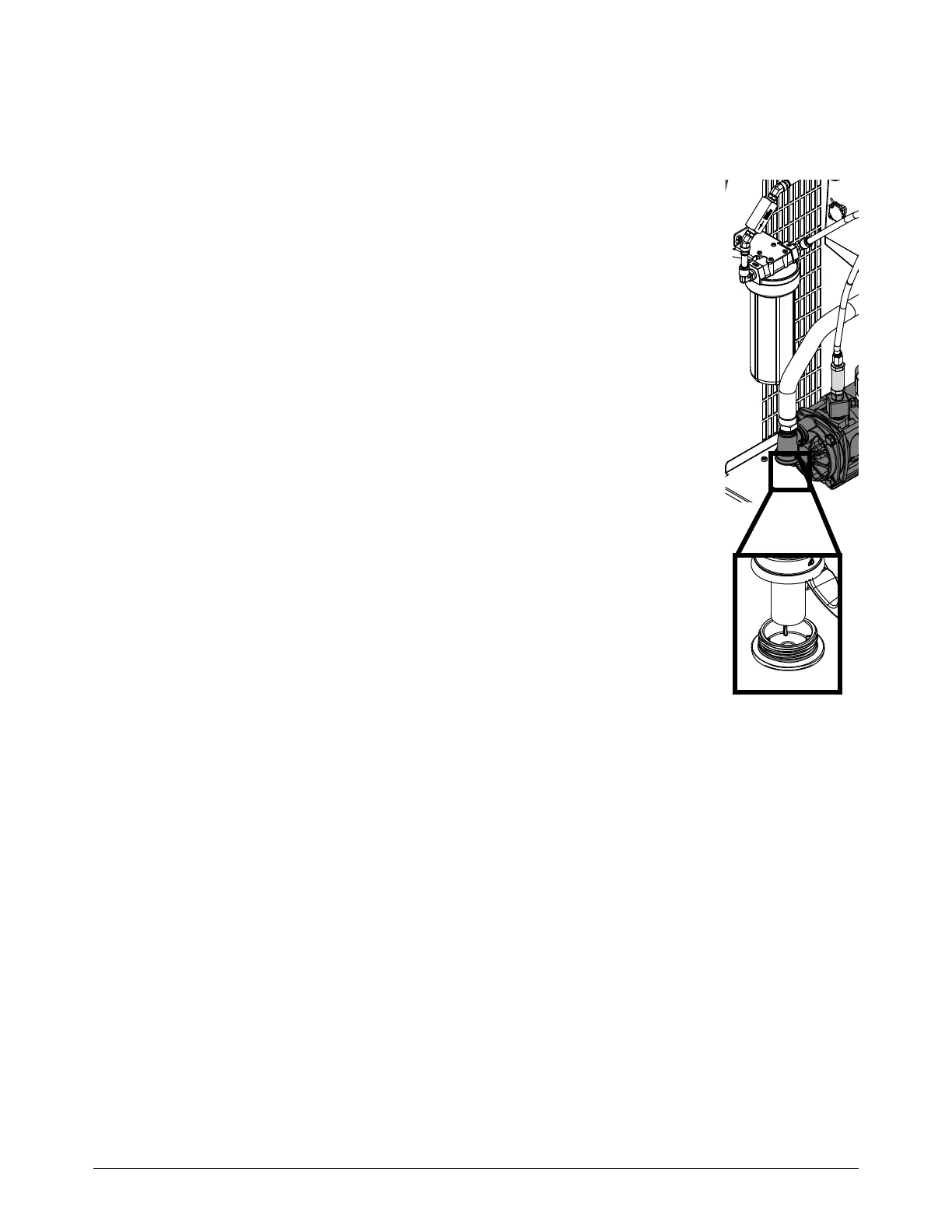

5. Clean and, if needed, replace the coolant pump screen:

a. Clean the coolant pump screen. Rinse it with water if you find debris.

b. Examine the coolant pump screen.

c. If you find damage on the coolant pump screen, replace it (127559).

d. Install the coolant pump screen.

e. Wipe the O-ring on the plug. Make sure that the O-ring is free of

debris, cracks, and nicks.

f. Install the plug on the coolant pump housing.

Loading...

Loading...