EN

5 - ADJUSTMENTS AND SETTING-UP BOSS 332/545/552 HD

5 - Pag. 34 / 34

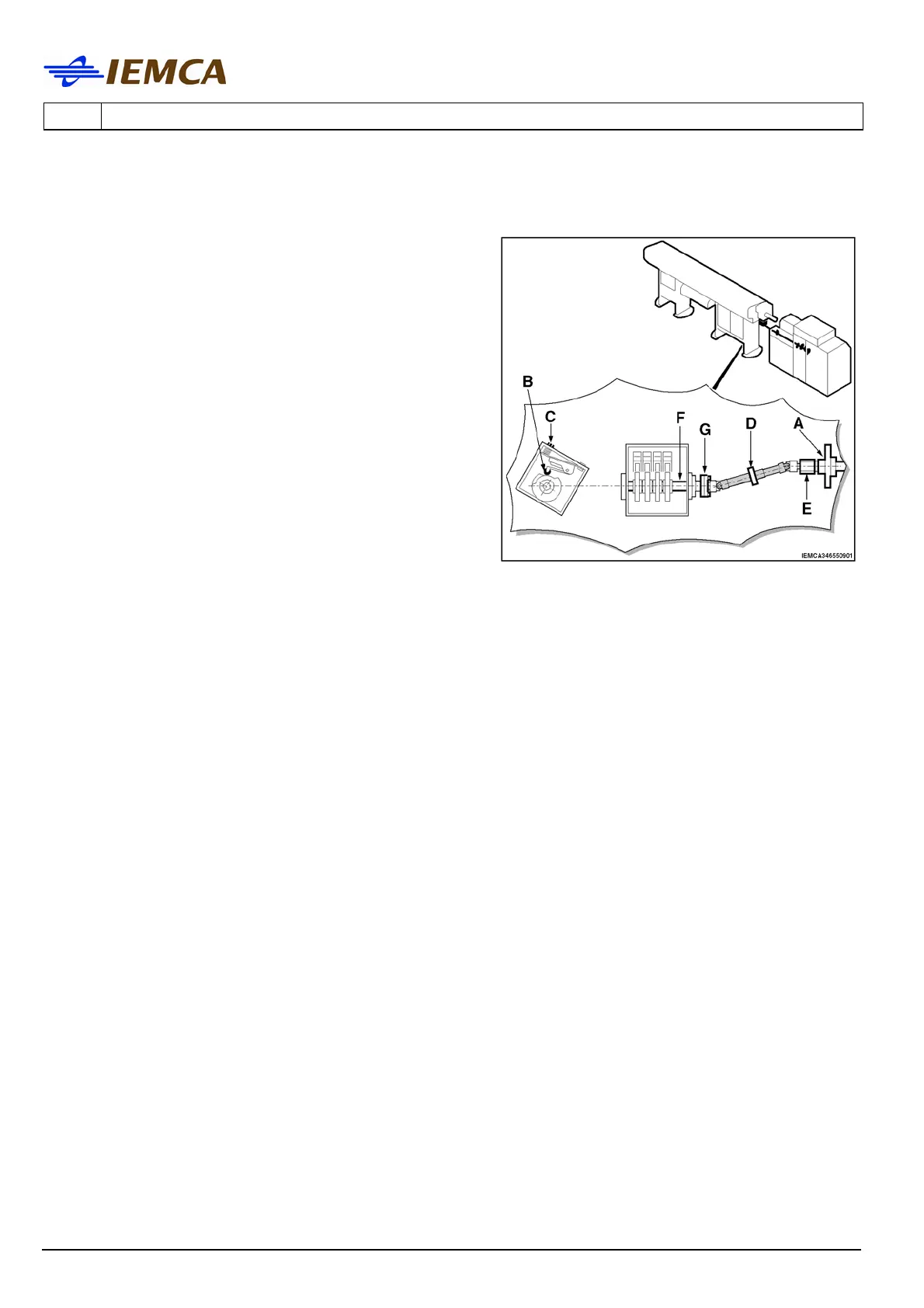

Microswitch S92

• Manually rotate shaft "A" until the headstock

starts its return stroke with closed collet.

• Release the "S92" microswitch wheel.

• Continue rotation until the headstock has

completed its return stroke.

• Lift the wheel "S92".

Microswitch S99

When the threading tool starts its return stroke,

lower "S99" microswitch wheel and lift it before the

stroke is over.

Should microswitch "S99" be fitted on lathe, timing

is to be performed on lathe cam.

GENERAL REMARKS

• Microswitch activation can be either delayed or

advanced through screw "C".

• Whenever servicing the camshaft, disconnect the lathe cam box, according to the following

procedure:

- loosen clamp "D" and unscrew sleeve "E";

- service the lathe camshaft;

- screw sleeve "E" and tighten clamp "D";

- should shaft "F" be out of phase, loosen the screws of sleeve "G", rotate it correctly and

tighten the screws.

Loading...

Loading...