Set point 1 is the pressure at which the pump will start and Set point 2 is the pressure at

which the pump will stop. For more details, see 3. Compressor control and surveillance.

2: Full flow pump (screw compressors)

No

Yes

Select Yes for VMY Mk3 compressor provided it is fitted with full flow pump.

Select No for all other compressor types.

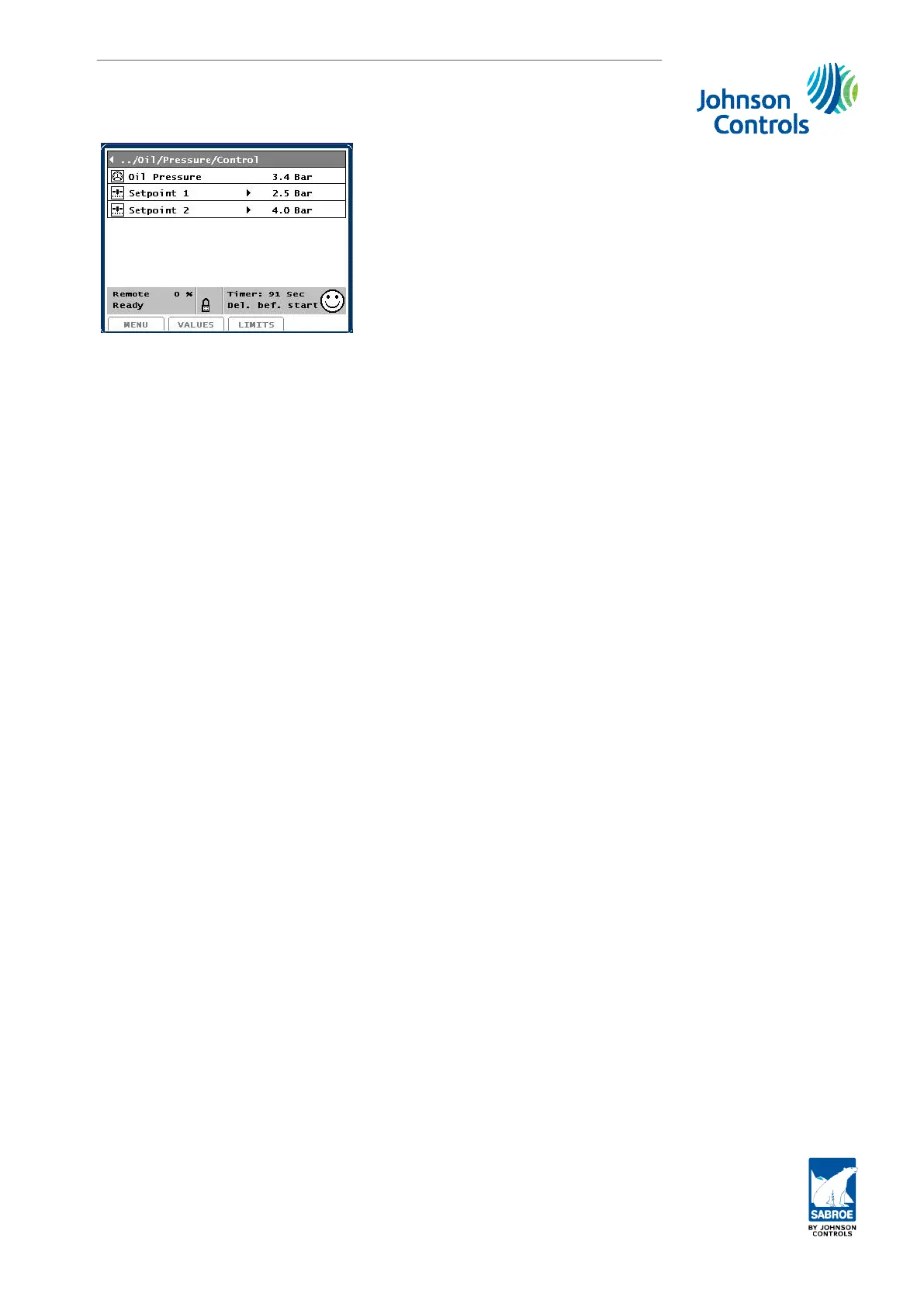

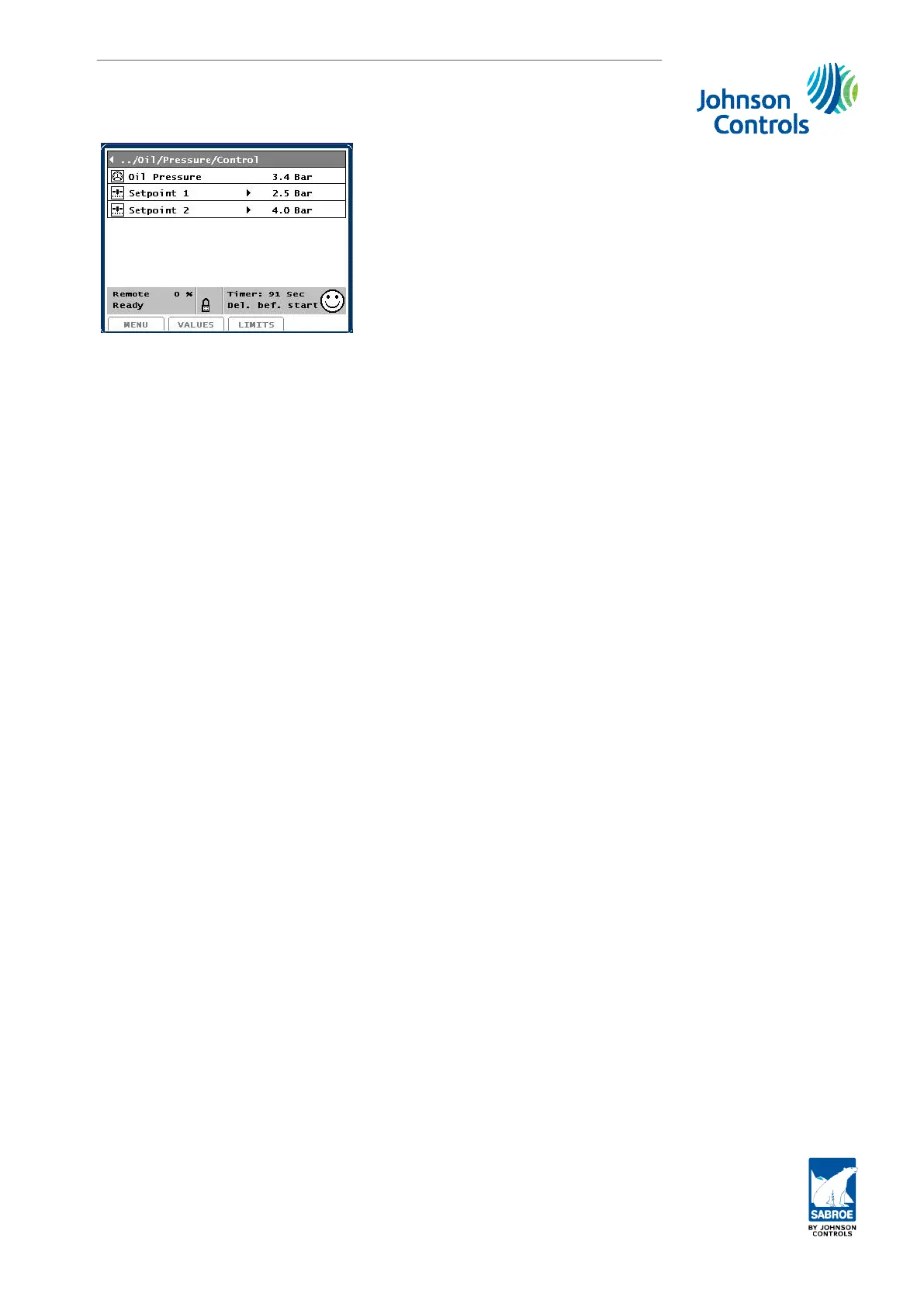

Use pump for prelubrication before start-up and to maintain minimum oil pressure during op-

eration. Remember to set Set points 1 and 2 as they determine the pressure levels where the

pump is going to start and stop. Select picture Control values/Oil/Pressure/Control.

Set point 1 is the pressure at which the pump will start. Select 5.5 bar.

Set point 2 is the pressure at which the pump will stop. Select 7.0 bar.

For more details, see 3. Compressor control and surveillance.

3: Oil cooling

1. None

2. Normal (Screw and reciprocating compr.)

3. HLI/BLI (Screw compressors)

4. Thermo pump (Reciprocating compr.)

5. 3-way-valve (Screw compressor)

6. HLI-AKV (Screw compressor)

7. HLI 4-20mA (Screw compressor)

8. Thermo pump internal (Reciprocating compr.)

None

Oil cooling is disabled.

Normal

Oil cooling output is activated by rising oil temperature. The set point for this value is set in

picture Control values/Oil/Temperature/Control Set point 1. The set point has a fixed hystere-

sis of 5K, i.e. cooling starts at set point 1 and stops at set point 1 - 5°C.

Screw default setting: Set point 1 = 50°C

SMC/CMO default setting: Set point 1 = 55°C

HPC/HPO default setting: Set point 1 = 65°C.

Oil cooling output is closed at compressor stop according to adjustable time delay. In Timers/

Timer setup adjust time delay Oil cool on.

HLI/BLI

Oil cooling output is activated by rising discharge temperature. The set point for this value is

set in Control values/Discharge/Temperature/Control Set point 1. The set point has a fixed

hysteresis of 2K.

Set-up

Engineering manual - Unisab III 1.10

001930 en 2014.09

193/319

Loading...

Loading...