3.3. Compressor control - screw compressors

3.3.1 Start sequence

The various types of reciprocating and screw compressors start up in different ways. Some

types have prelubrication and others start up directly. They all have certain alarms which are

suppressed at this stage as described in chapter 2. Alarms and shutdowns and section

6.5. Timers.

The starting sequence and alarm surveillance are described for a number of different screw

compressor types in subsections 3.3.2. to 3.3.20.

3.3.2 SAB 163 Mk 1 with oil pump

Once the compressor has received starting permission, the pump will start. The built-in spring

ensures that the capacity slide is in minimum position.

The oil is pumped into the compressor lubrication system and when the oil flow switch is acti-

vated, the prelubrication period will begin. When this period has expired, the compressor will

start and the pump will work for 300 seconds and then stop.

On booster compressors the pump will run continually during operation to ensure sufficient

pressure to move the capacity slide. See also section 6.5. Timers.

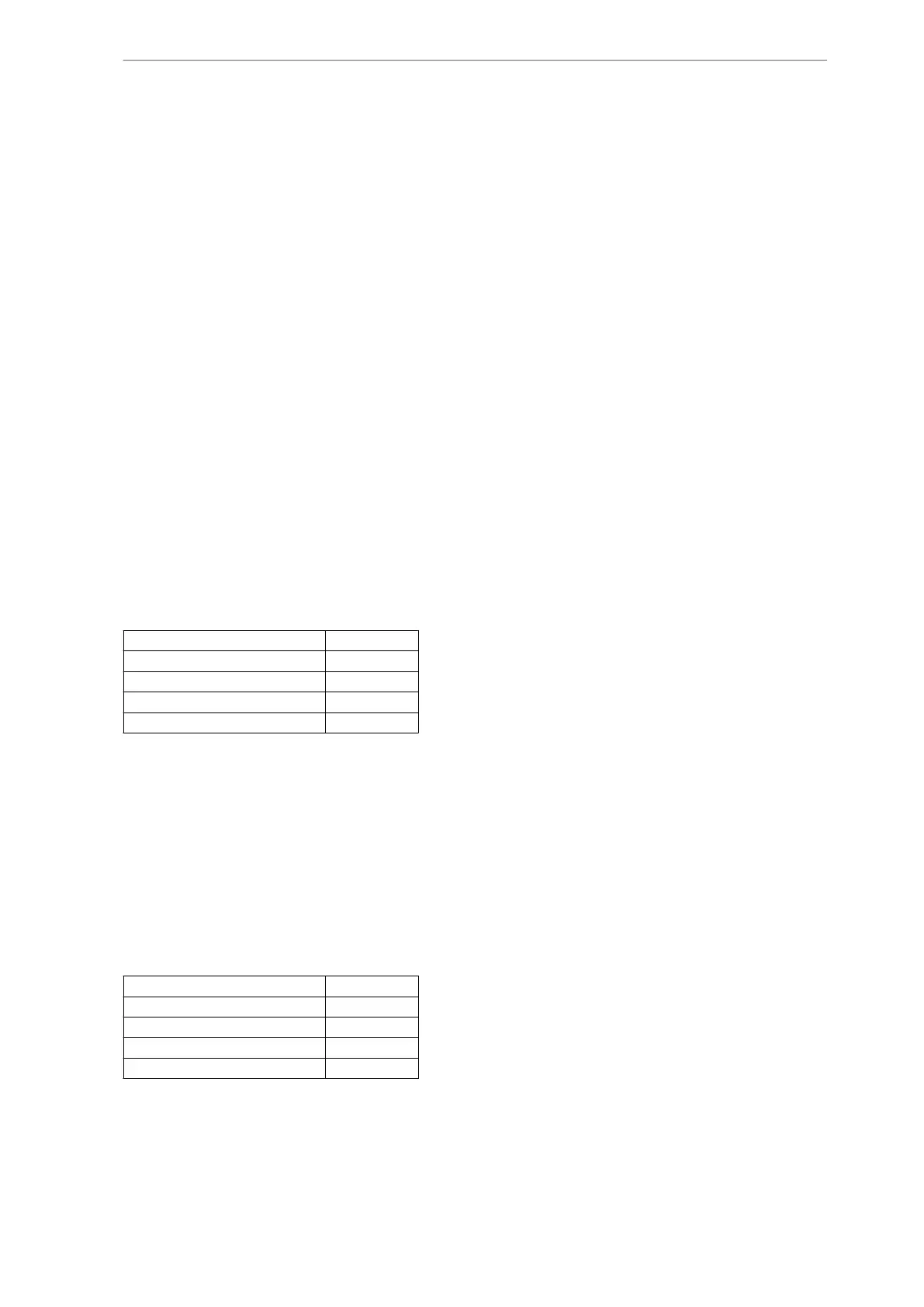

Alarm surveillance

During start the following alarms are delayed:

Low oil pressure 300 sec.

High filter diff. pressure 300 sec.

Low superheat 300 sec.

High superheat 300 sec.

Low/high oil temperature 300 sec.

See also section 6.5. Timers.

3.3.3 SAB 110/128/163 Mk 2 without oil pump

Once the compressor has received starting permission, the built-in spring ensures that the ca-

pacity slide is in minimum position. Start the compressor and wait for a signal from the oil

flow switch for max. 50+10 seconds. If there is no signal from the oil flow switch for 10 sec-

onds during operation, the compressor will stop.

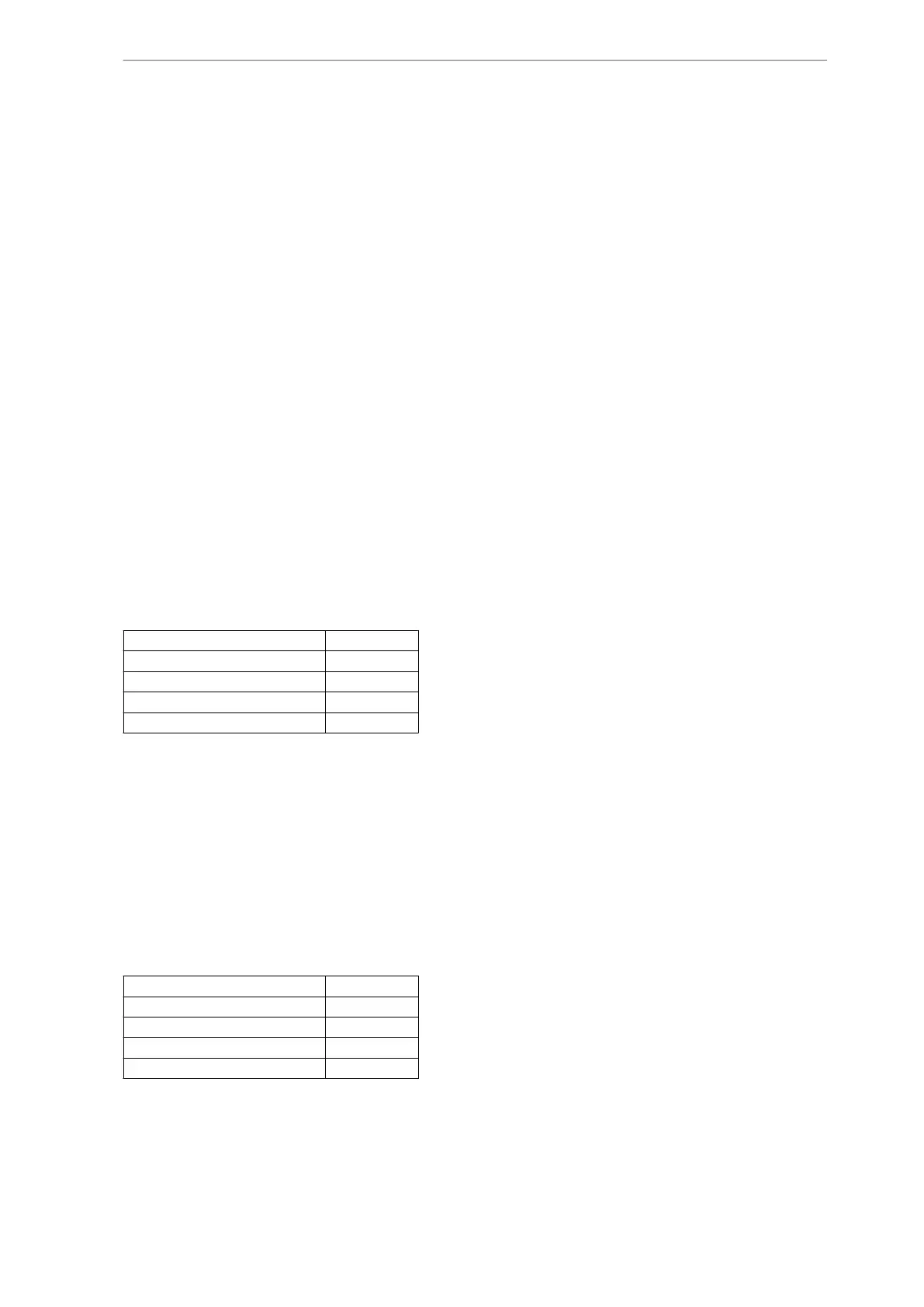

Alarm surveillance

During start the following alarms are delayed:

Low oil pressure 45 sec.

High filter diff. pressure 300 sec.

Low superheat 300 sec.

High superheat 300 sec.

Low/high oil temperature 300 sec.

See also section 6.5. Timers.

Compressor control and surveillance

96/319

Engineering manual - Unisab III 1.10

001930 en 2014.09

Loading...

Loading...