7. Calibration

7.1. Before start-up

Before initial compressor start-up and after service, adjustment of transducers and position

transmitters must be carried out. Their values are usually preset from factory but must be re-

checked before start-up. This is very important as failure to adjust the values may cause mal-

functioning during operation. Service may e.g. be in connection with replacement of print cas-

sette, pressure transducers, position transmitters or battery. See also chapter 10. Parts re-

placement.

Insufficient or incorrect setting of pressure transducers may cause compressor

breakdown or personal injury.

The temperature sensors must not be calibrated as they are connected electrically with four

conductors which automatically makes up for line resistance.

7.2. Pressure transducers

Calibrate the pressure transducers at atmospheric pressure in the compressor.

Use the following pressure transducers:

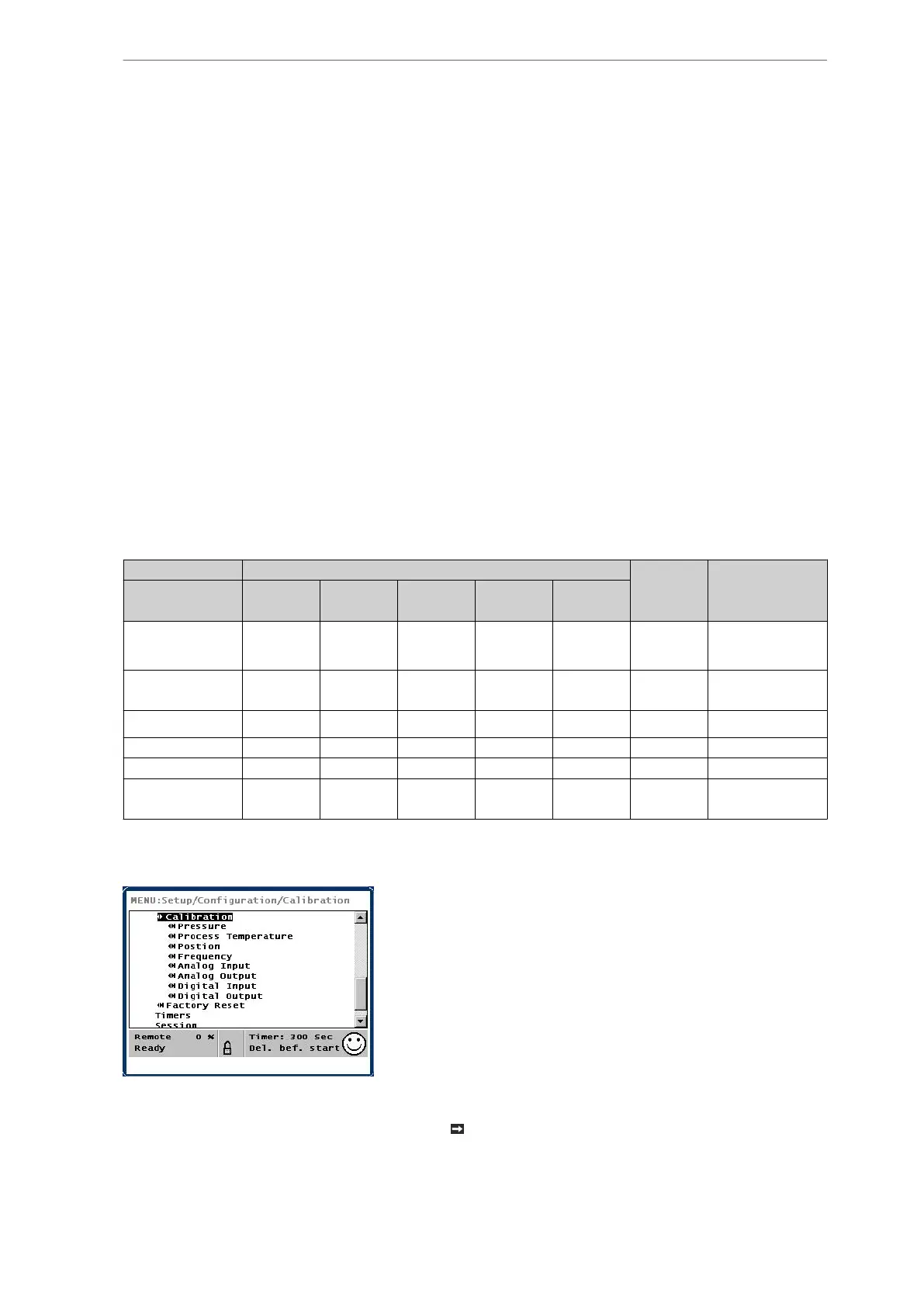

Unit = bar Compressor type

Max.

press.

Max. permissi-

ble deviation

at Atm. press

Meas. point

SAB/

VMY SMC

TSMC/

TCMO HPC HPO

Suct. press. -1 - +9 -1 - +9 -1 - +9 -1 - +25 -1 - +25

33

55

+/- 0.2

+/- 0.5

Disch. press. -1 - +25 -1 - +25 -1 - +25 -1 - +59 -1 - +59

55

200

+/- 0.5

+/- 1.2

Oil press. -1 - +25 -1 - +25 -1 - +25 -1 - +59 -1 - +25 55 +/- 0.5

Diff. press. -1 - +25 -1 - +59 55 +/- 0.5

Interm. press. -1 - +25 55 +/- 0.5

Internal suc-

tion pressure

-1 - +9 33 +/- 0.2

Table 51: Pressure transducers

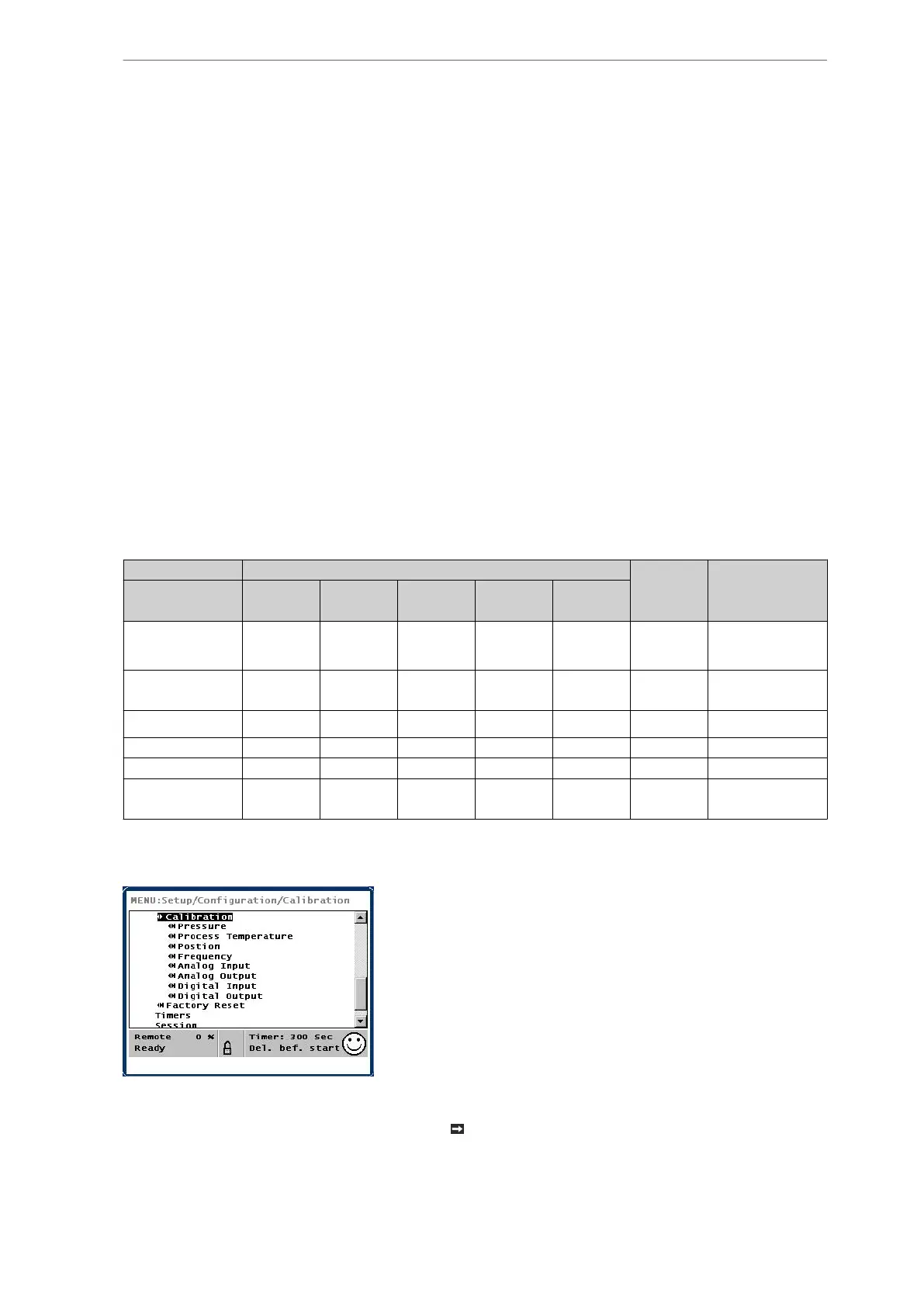

Select the menu Setup/Configuration/Calibration and the following picture will appear:

Note that some of the entries in the Calibration menu are described in other chapters of this

manual. With the cursor on Pressure, press and the following picture will appear:

Calibration

236/319

Engineering manual - Unisab III 1.10

001930 en 2014.09

Loading...

Loading...