7.4. Motor

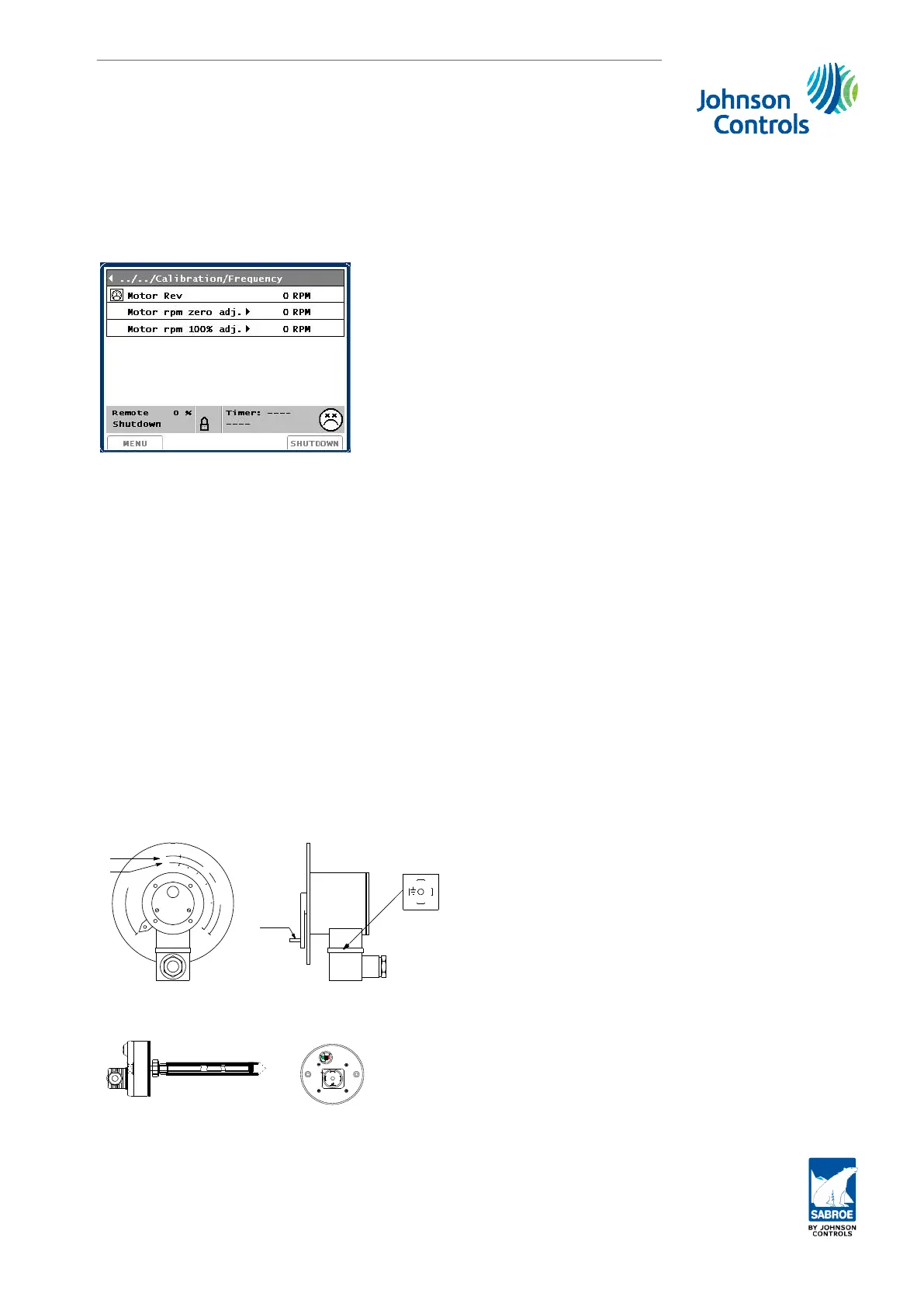

7.4.1 Motor frequency signal

When compressor capacity is regulated wholly or partly by changes in the motor speed, the

motor frequency signal from the frequency converter can be calibrated in this menu:

7.4.2 Motor current

The reading of motor current can be calibrated as described in subsection 6.4.1. Drive.

7.5. Position transmitters for hydraulic slide systems (screw compres-

sors)

The built-in capacity slide position transmitter and the Vi slide position transmitter must be

adjusted correctly in the mechanical minimum and maximum position to ensure safe and reli-

able slide control. This adjustment must always be carried out mechanically on the transmit-

ter or by using software calibration in Unisab III if the transmitter cannot be calibrated. Fur-

thermore, the slide speed must be adjusted to avoid hunting. See also section 3.7. Compres-

sor control - adjusting slide speed (screw compressors with hydraulic slides).

To measure slide position the compressor is fitted with a position transmitter which yields

4-20 mA to Unisab III. A transmitter is always fitted at the capacity slide and one may be fit-

ted at the volume ratio slide if the compressor is made for automatic Vi regulation.

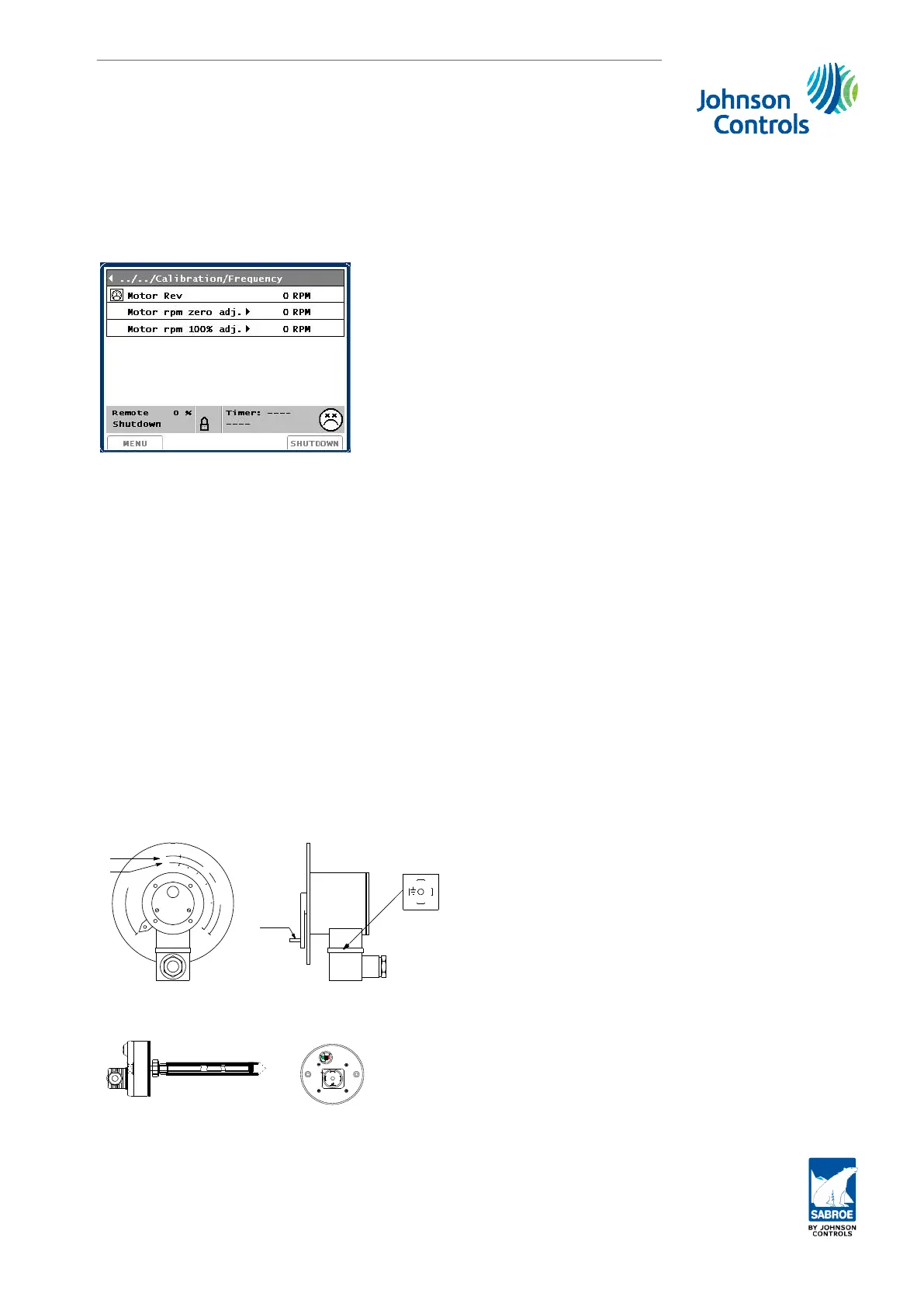

There are six types of position transmitters:

1

3

No. 3

2

0%

2.

2.5

3.

4.5

4.

3.5

SPAN+ZERO

100%

Fig. 24: Turning transmitter for SAB 110-128-163 and SAB 202 (capacity and Vi)

3

2

1

ALU tube

Fig. 25: Long-stroke capacity rod transmitter for SAB 110-128-163-202, SAB 81-89 and SAB 330 (capaci-

ty and Vi)

Calibration

Engineering manual - Unisab III 1.10

001930 en 2014.09

239/319

Loading...

Loading...