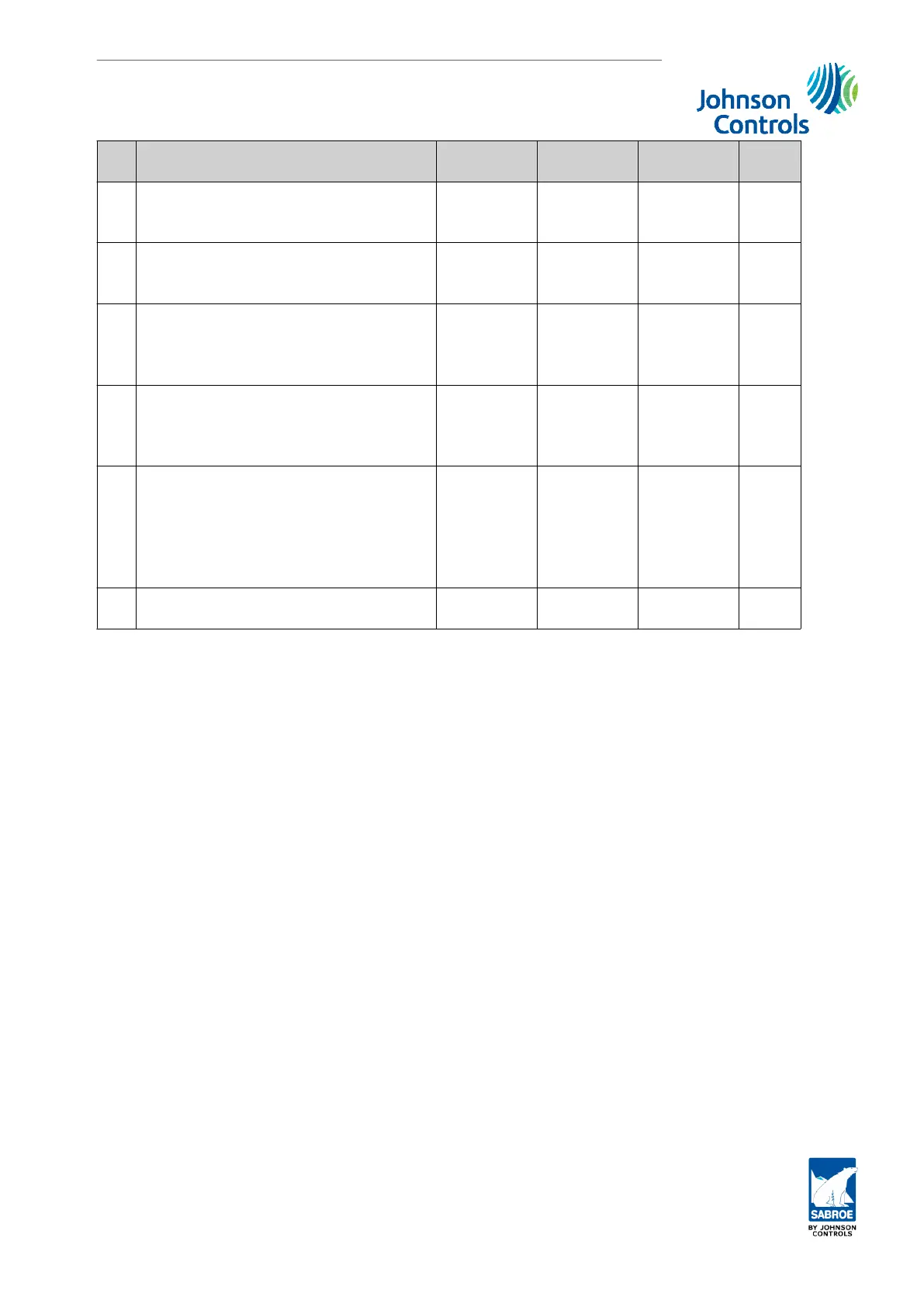

No. Type of regulator Minimum Maximum

Factory

setting

Unit

2 Normal oil cooling

Set point 1/oil temperature

Hysteresis

35 75 50

5 (fixed)

°C

°C

3 HLI/BLI cooling

Set point 1/discharge pipe temperature

Hysteresis

-20 150 65

2 (fixed)

°C

°C

5 3-way valve

Set point 1/oil temperature

Neutral zone

Prop. band oil cooling

35

0

0

75

100

100

50

4

4

°C

°C

°C

6 HLI-AKV oil cooling

Set point 1/discharge pipe temperature

Neutral zone

Prop. band

-20

0

1

150

10

100

65

0

10

°C

°C

°C

7 HLI 4-20 mA oil cooling

Set point 1/discharge pipe temp.

Neutral zone

Prop. band

T.int.

T.diff.

40

0

1

1

0

80

10

100

999

999.9

65

0

30

10

0

°C

°C

°C

sec.

sec.

8 Thermo pump internal

Set point 1/discharge pipe temperature 70 90 80 °C

Table 45: Oil cooling setting - screw compressors

4: Oil controller

I

PID

Select PID for applications where a change in the cooling requirement must be met by a fast

change in cooling capacity. PID is selected as standard.

5: Water cooling (reciprocating compressors)

No

Yes

Water cooling output is activated by rising discharge pipe temperature. The set point for this

value is set in Disch. Temp/Parameter, Set point 1. The set point has a fixed hysteresis of 5K.

Example:

Sp 1 = 100°C:

Cooling starts at 100°C and stops at (100-5) = 95°C.

Water cooling output is closed at compressor stop according to adjustable time delay. In

Timers/Timer setup adjust time delay Oil cool on.

Intermediate pressure liquid injection (Two stage reciprocating compressors)

The intermediate pressure liquid injection for TSMC/TCMO compressors is active whenever the

compressor is configured to TCMO or TSMC. The solenoid valve for intermediate pressure liq-

uid injection is activated when the compressor has started and the discharge pipe tempera-

ture gets too high. The set point for this value is entered in Control values/Discharge/Temper-

ature/Control, Set point 2. The set point has a fixed hysteresis of 5°K.

Set-up

Engineering manual - Unisab III 1.10

001930 en 2014.09

195/319

Loading...

Loading...