M A E D A Crawler Crane 6.17 PERIODIC MAINTENANCE

5/2020 CC1908S-1 6-47

BEWARE OF HIGH-PRESSURE FUEL

The engine fuel pipes are pressurised while the

engine is running. Before inspecting fuel pipes,

wait for the internal pressure to drop. Wait at least

30 seconds after stopping the engine before

starting inspection work.

HANDLING HIGH-PRESSURE HOSES AND

PIPES

If fuel leaks from hoses or pipes, there is a risk of

fire and malfunction leading to serious personal

injury.

If hose or pipe mounts have loose joints or if oil or

fuel is leaking therefrom, immediately stop the

work in progress and retighten them to the

specified tightening torque.

If hoses or pipes become damaged or deformed,

contact us or our sales service agency.

If any of the following conditions are found,

replace the faulty parts:

• Damage to hoses or deformation of connectors

• Damage or cuts in the coating or exposure of

the wire reinforcement layer

• Partial swelling of the coating

• Signs of twisting or collapsing on the movable

parts of hoses

• Foreign objects embedded in the coating

BEWARE OF HIGH VOLTAGE

During engine operation or immediately after

stopping the engine, the engine controller interior

and around the engine fuel injector will be at high

voltage. There is therefore a risk of electric shock.

Never touch the inside of the engine controller or

engine fuel injectors. If there is a need to touch

these parts for some reason, contact us or our

sales service agency.

BEWARE OF NOISE

Wear ear defenders or ear plugs when exposed to

noise for long periods such as when servicing the

engine. There is a risk of hearing impairment or

deafness from the loud noise in the vicinity.

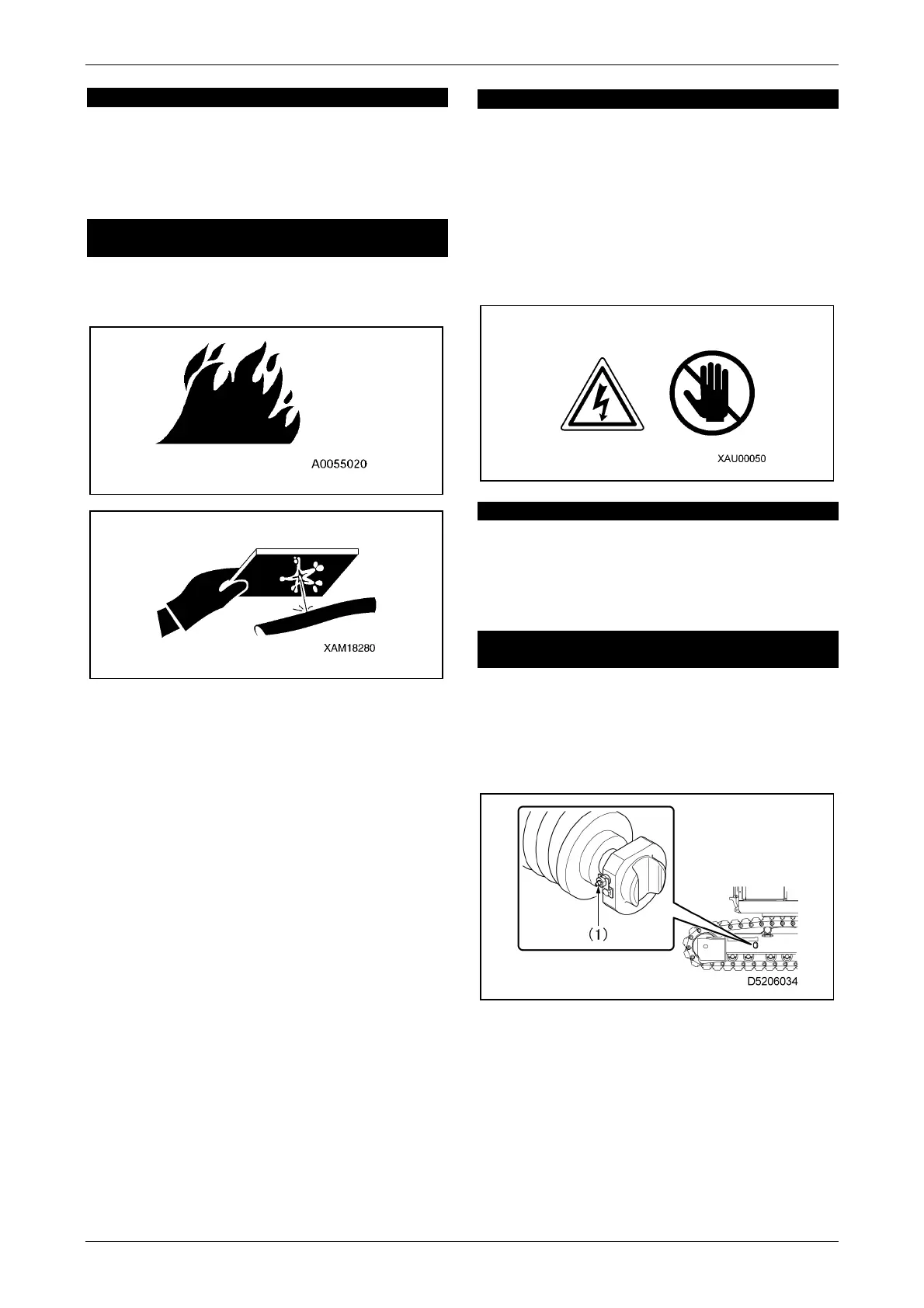

BEWARE OF HIGH-PRESSURE GREASE

WHEN ADJUSTING CRAWLER TENSION

• The grease inside the crawler adjusting unit is

under high pressure.

Adjusting using unauthorized procedures may

cause the grease discharge plug (1) to fly out,

resulting in serious personal injury.

• When loosening the grease discharge plug (1)

to reduce the crawler tension, do not rotate it by

more than one turn. Likewise, loosen the

grease discharge plug (1) slowly.

Loading...

Loading...