M A E D A Crawler Crane 6.18 IRREGULAR MAINTENANCE

5/2020 CC1908S-1 6-87

CRAWLER TRACK

TENSION

INSPECTION/ADJUSTMENT

The pins and bushings around the undercarriage

of the machine will wear differently depending on

the working conditions and soil quality. Check the

tension of the crawler tracks at any time to

maintain the prescribed tension.

Inspect and adjust on firm, level ground.

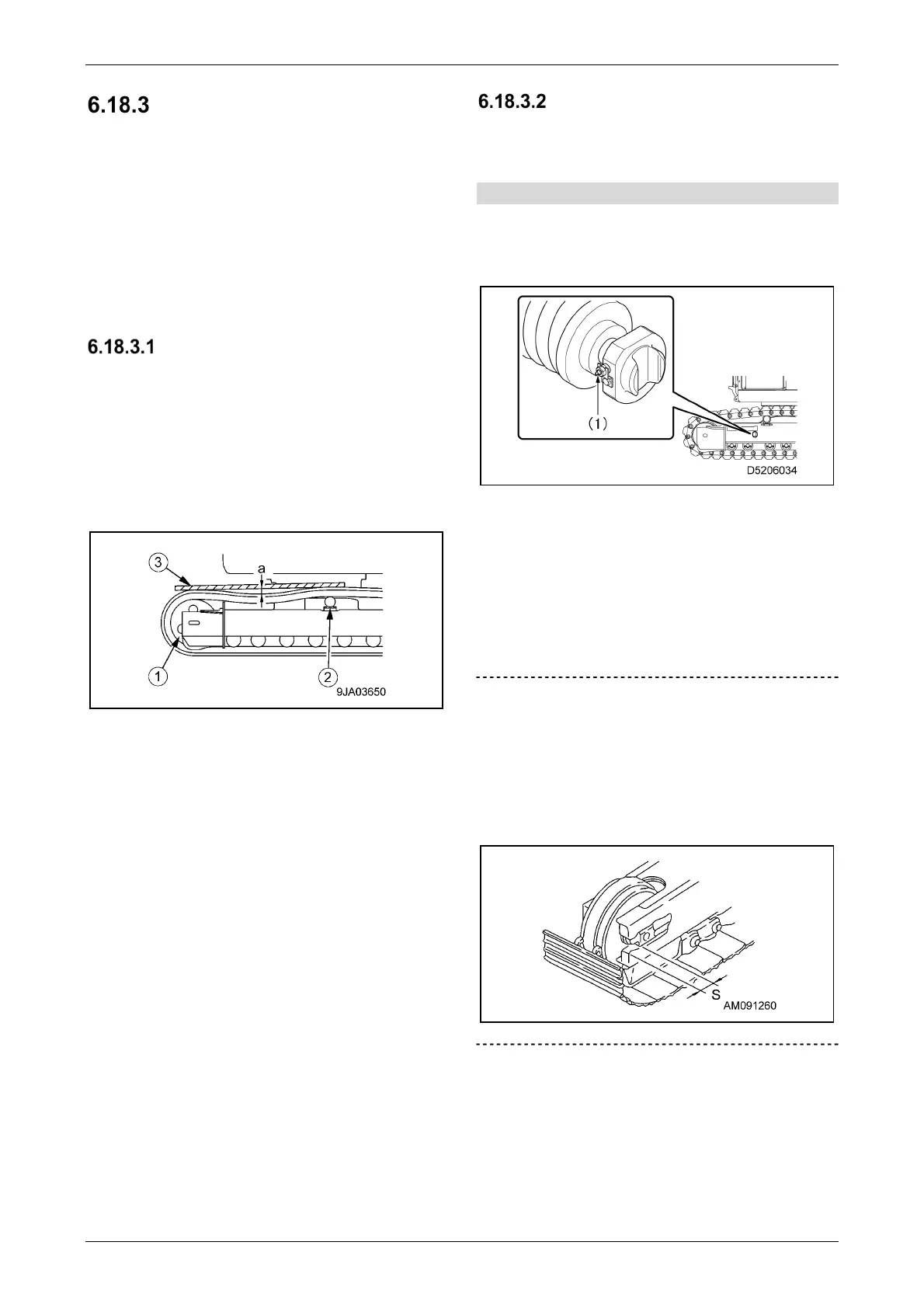

INSPECTION

1.

Keep the engine at low idle to allow the

machine to move forward a distance equal to

the length of the crawler tracks in contact with

the ground, and slowly bring it to a stop.

2.

Place a square bar (3) that can reach

between the idler (1) and upper rolling wheel

(2) on the crawler track.

3.

Measure the maximum sagging dimension

between the upper plane of the crawler track

and the bottom face of the square bar.

Reference value for sagging dimension (a):

10 mm to 30 mm is the normal range.

ADJUSTMENT

If inspection reveals that the tension differs from

the standard value, adjust it as follows:

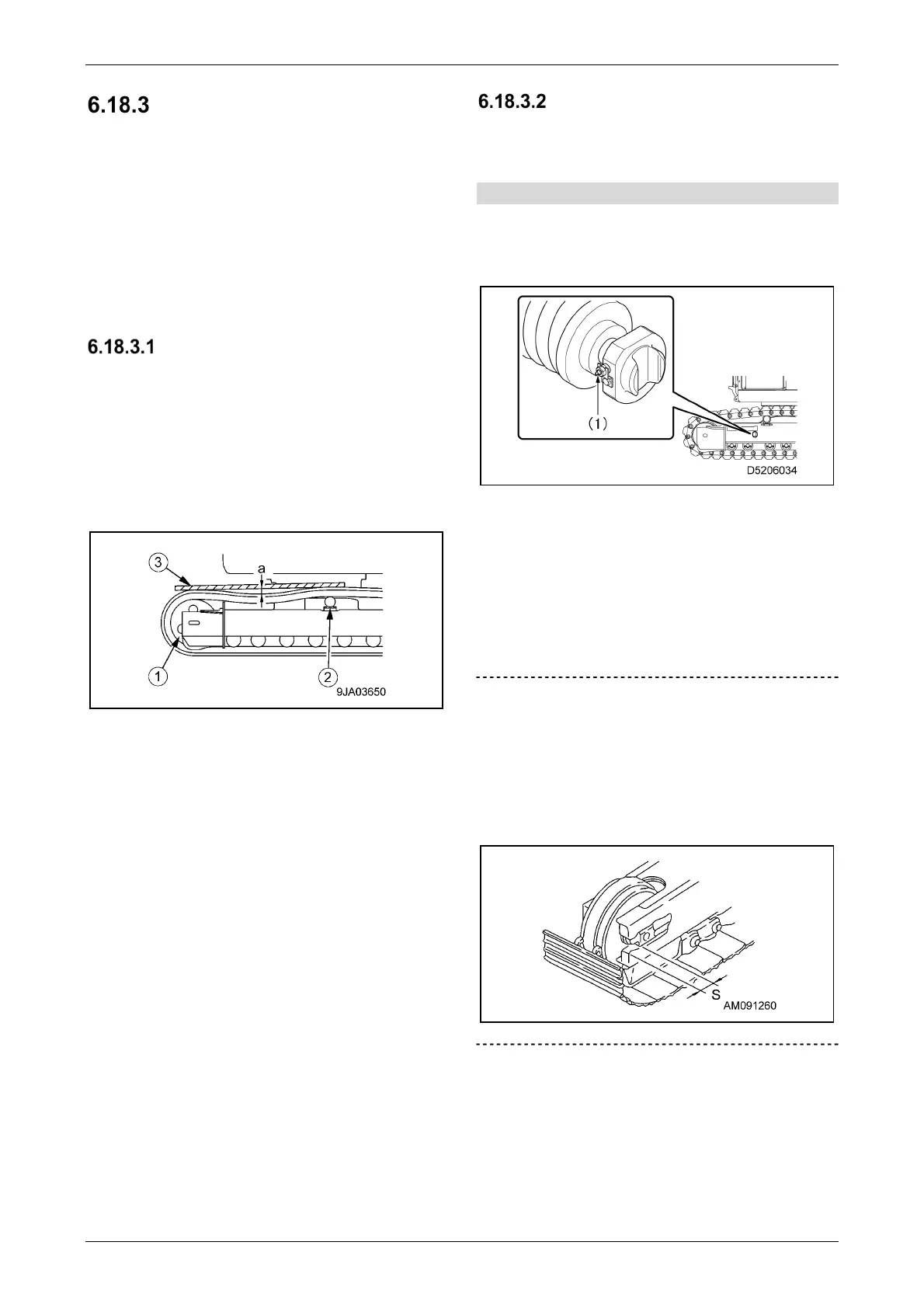

[1] Increasing tension

• Prepare a grease gun.

1.

Using the grease gun, inject grease through

the grease plug (1) opening.

2.

To ensure that the correct tension is applied,

keep the engine at low idle to move forward a

distance equal to the length of the crawler

tracks in contact with the ground, and then

slowly stop.

3.

Check the tension of the crawler tracks again.

If the tension is not correct, readjust.

IMPORTANT

Until dimension (S) reaches 0 mm, grease can

be injected. However, if the tension is still

insufficient, pins and bushings will be subject

to significant wear.

As reversing or replacement of pins and

bushings is required, contact us or our sales

service agency for repairs.

Loading...

Loading...