M A E D A Crawler Crane 6.3 LEGAL INSPECTION

5/2020 CC1908S-1 6-7

LEGAL INSPECTION

INSPECTION PRECAUTIONS

1.

Inspect safety devices to check that there are no

abnormalities.

2.

Inspect the hook block and other hoisting

accessories for any abnormalities.

3.

Inspect the winch wire rope end and wire clip for

damage.

4.

Replace the wire rope promptly if it is damaged.

5.

Inspect the hydraulic hoses for oil leaks and

surface wear damage. Replace the hose if

surface damage is found.

6.

Inspect the boom and other structural parts for

cracking and deformation.

7.

Inspect the mounting bolts and joints for

looseness and detachment.

8.

Check that the crane operates and stops

correctly when boom telescoping, derricking, and

slewing.

If any faults are discovered during inspection, contact

us or our sales service agency.

PARTS REPLACEMEMT

PERIODIC REPLACEMENT

OF CRITICAL PARTS

To assure prolonged and safe use of the machine, be

sure to periodically replace the parts listed in the

critical parts list, especially those related to safety and

fire.

These parts are prone to degradation over time and

abrasion. As the extent of degradation and

deterioration cannot be easily determined during

periodic maintenance, they must be replaced at the

prescribed intervals even if no abnormality is found in

order to maintain correct functioning at all times.

If any abnormality is found in any of these parts, they

must be replaced even if it is before the

predetermined time for replacement.

In the case of hoses, if any signs of degradation are

detected, such as deformation or cracking of the

clamps, the clamps must be replaced at the same

time.

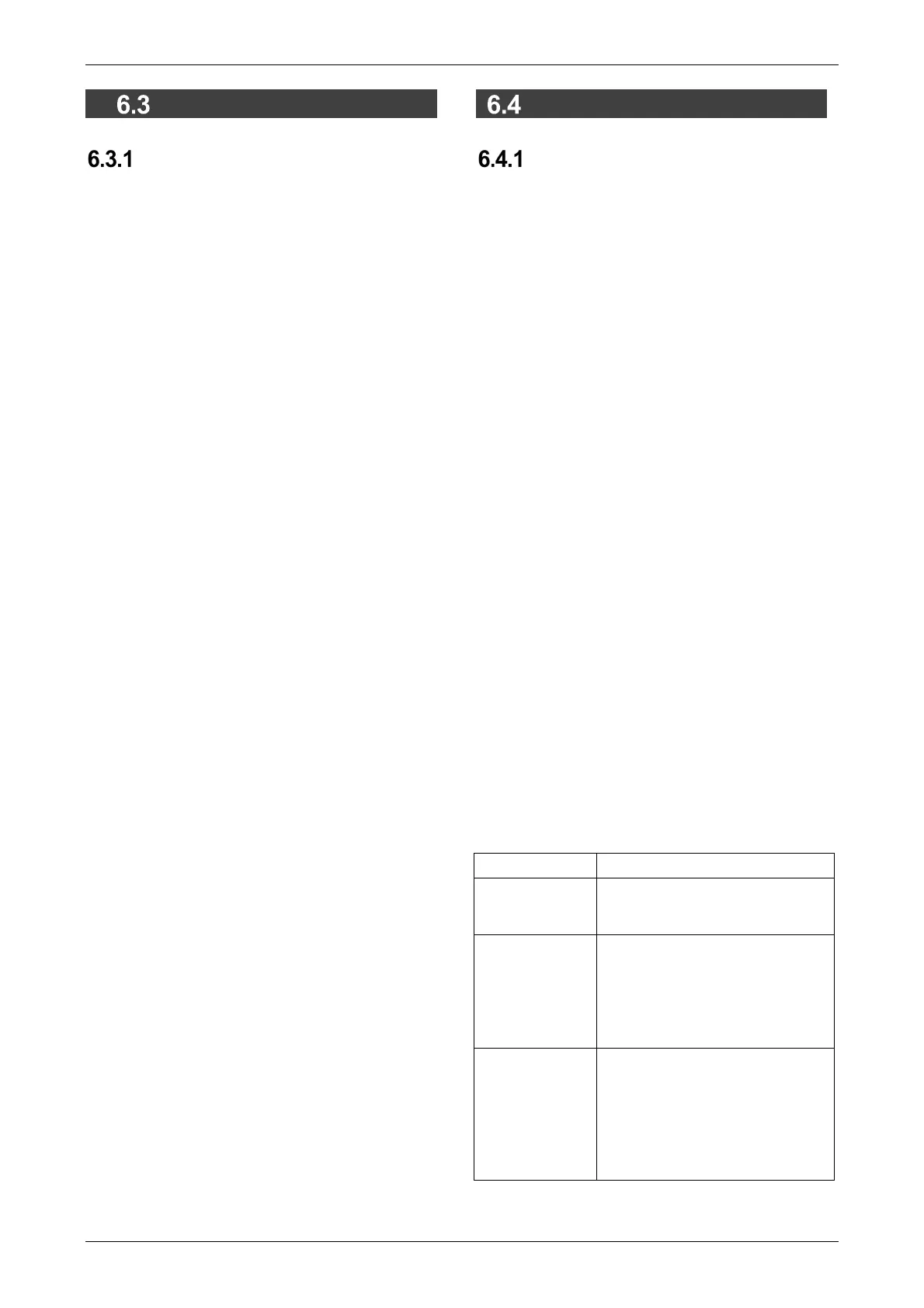

Also conduct the periodic inspections indicated in the

following table for hydraulic hoses other than the

periodic replacement part. If any abnormality is found,

retighten or replace.

• When replacing hoses, also replace the O-rings

and gaskets at the same time.

• Contact us or our sales service agency for the

replacement of critical parts.

• When conducting the periodic inspection indicated

in the following table, also inspect the hydraulic

hoses and fuel hoses.

Inspection type Check items

Daily inspection

(before starting

work)

Oil leakage from the joints and

caulking of fuel hoses and

hydraulic hoses

Monthly

Inspection

Oil leakage from the joints and

caulking of fuel hoses and

hydraulic hoses

Damage to fuel hoses and

hydraulic hoses (cracking,

abrasion, and tearing)

Specified user

inspection

(annual

inspection)

Oil leakage from the joints and

caulking of fuel hoses and

hydraulic hoses

Interference, collapsing, ageing,

twisting, and damage (cracking,

abrasion, and tearing) of fuel

hoses and hydraulic hoses

Loading...

Loading...