6.18 IRREGULAR MAINTENANCE M A E D A Crawler Crane

6-86 5/2020 CC1908S-1

3.

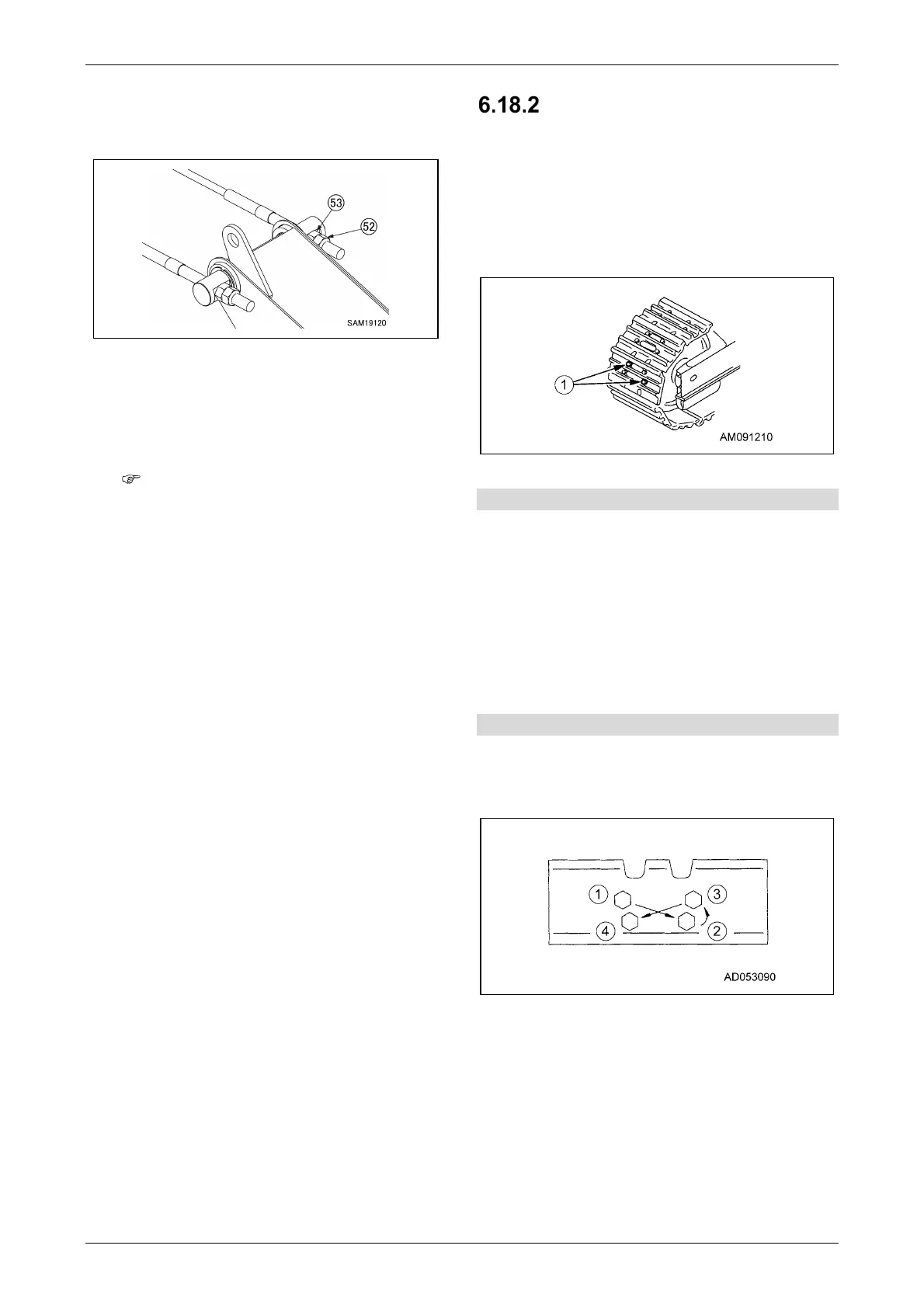

Loosen the lock nut (52), adjust the wire rope

using the adjustment nut (53), and set the

No.1 fly jib to the horizontal.

• If the No. 1 fly jib is below the horizontal:

Tighten (clockwise) the adjustment nut

(53).

• If the No. 1 fly jib is above the horizontal:

Loosen (counterclockwise) the

adjustment nut (53).

There are adjustment nuts (53) on both

the left and right sides, but the derrick

wire rope is connected to just one, so

you can adjust to horizontal using either

one.

4.

Tighten the lock nut (52).

5.

Align the machine bolt (51) so that it lightly

makes contact with the upper surface of the

No. 1 fly jib, then tighten the nut (50).

CRAWLER TRACK SHOE

BOLT LOOSENESS

INSPECTION/

RETIGHTENING

Using the machine with loose crawler track shoe

bolts (1) will cause the bolts to break. Retighten

the bolts if found to be loose.

[1] Retightening

1.

Remove the rubber pad.

2.

After tightening the bolts to a tightening

torque of 765 Nꞏm +/-78 Nꞏm [78 kgfꞏm +/-8

kgfꞏm], ensure that the nuts and shoes make

tight contact with the link mating surfaces.

3.

After checking, retighten them at a tightening

angle of 90 +/-10 degrees.

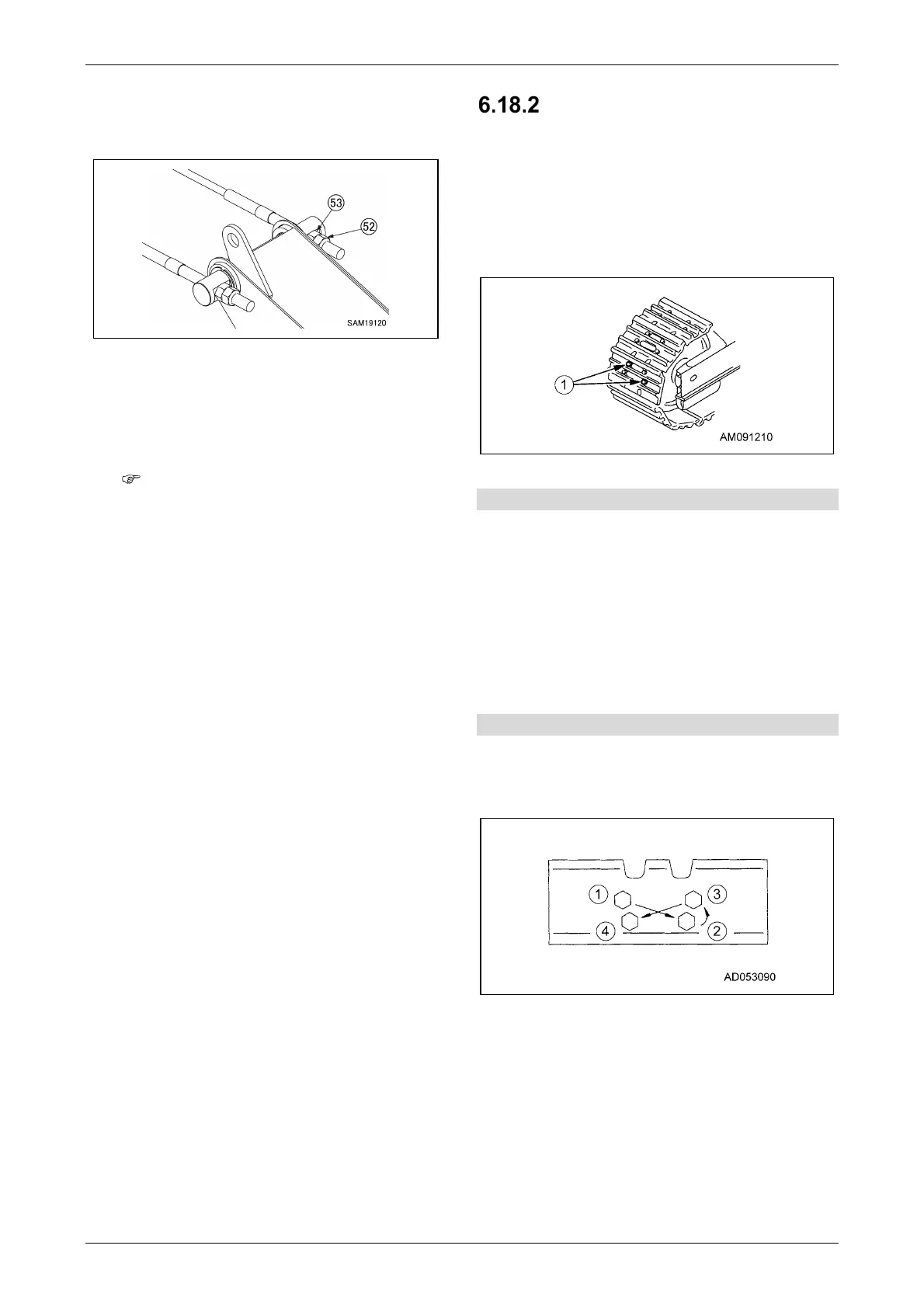

[2] Tightening sequence

Tighten the bolts in the order indicated in the

diagram.

After tightening, check that the nuts and shoes are

a tight fit with the link mating surfaces.

Loading...

Loading...