6.20 TROUBLESHOOTING M A E D A Crawler Crane

6-104 5/2020 CC1908S-1

TROUBLESHOOTING

• Make sure you contact us or our sales service agency for the actions marked with ★ in the table.

• Contact us or our sales service agency if you suspect any abnormalities or causes not described here.

• If an error code is displayed on the monitor, refer to "6.21.3 MONITOR ERROR CODES" on P. 6-115

and take the corrective action described there.

• If the monitor does not display correctly, stop using the crane immediately and contact us or our sales

service agency.

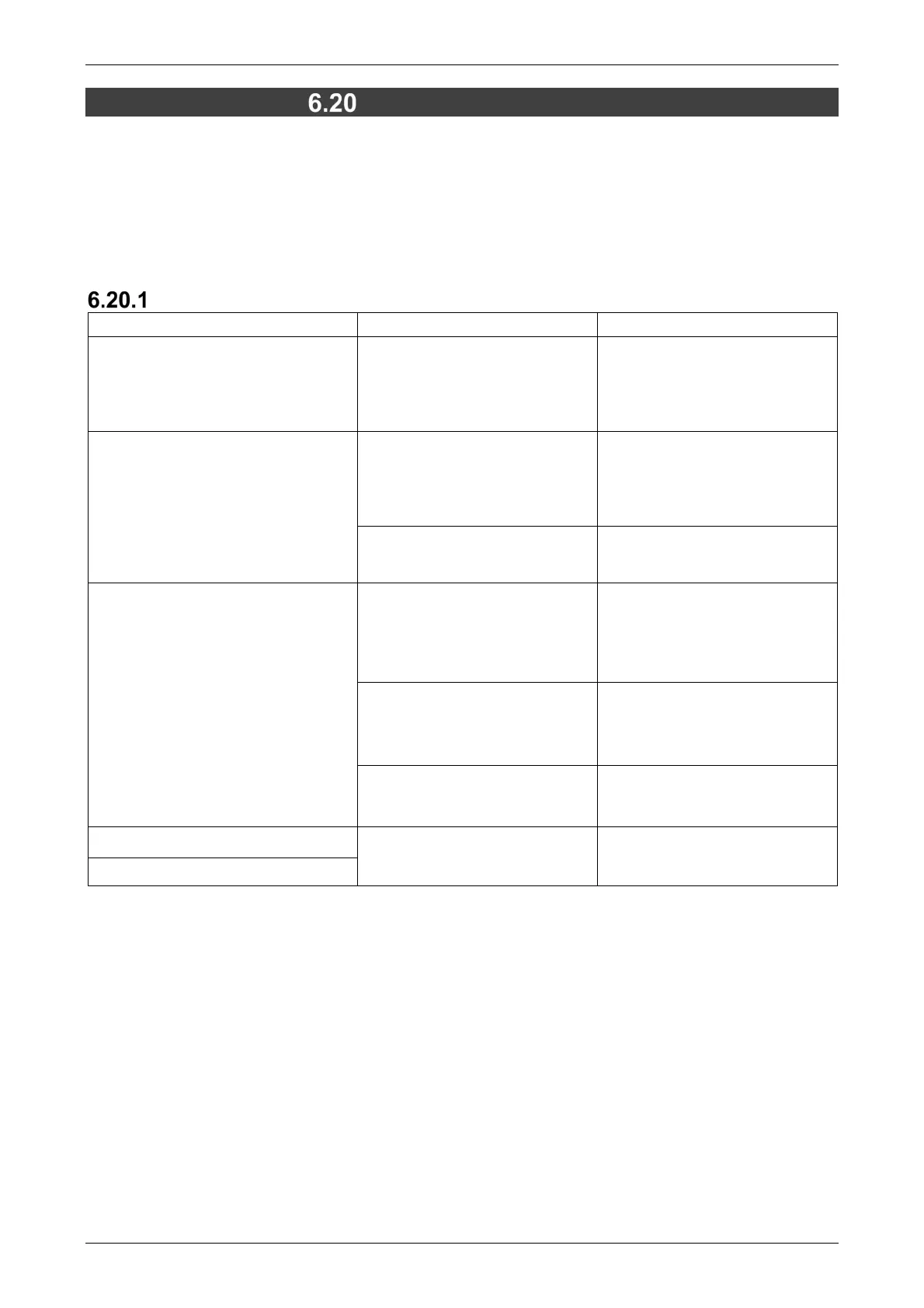

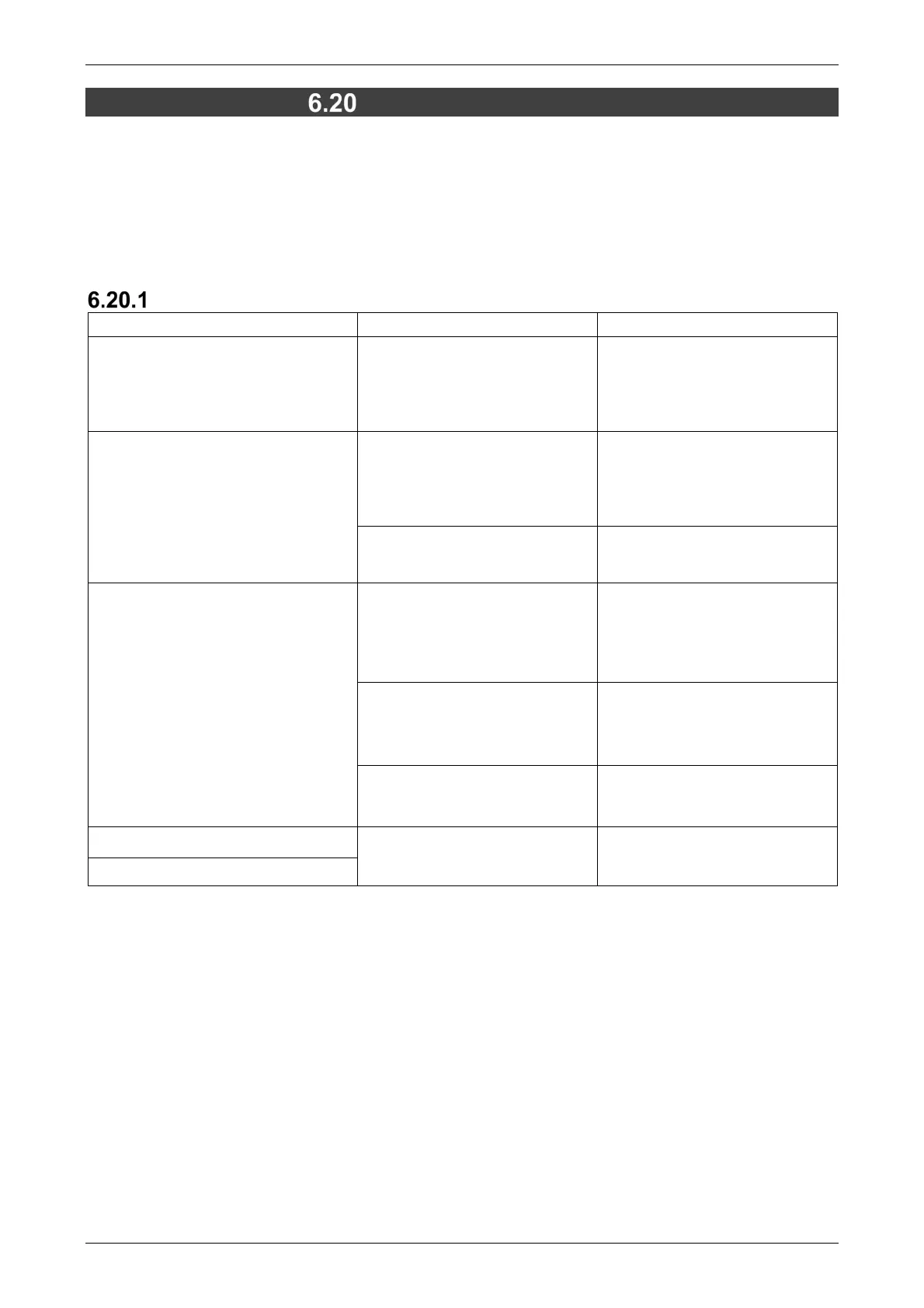

MACHINE BODY

Abnormal phenomenon Main causes Corrective action

Travel speed, slewing speed, boom

and hook block operation speed too

slow

Insufficient hydraulic oil

Refer to "6.16.1

PRE-OPERATION

INSPECTION" on P. 6-27 and

replenish the hydraulic oil to the

specified level.

Abnormal noise from pump

(Air suction)

Insufficient hydraulic oil

Refer to "6.16.1

PRE-OPERATION

INSPECTION" on P. 6-27 and

replenish the hydraulic oil to the

specified level.

Hydraulic oil tank strainer

element clogging

Refer to "6.17.12

MAINTENANCE EVERY 5,000

HOURS" on 6-73 and wash.

Hydraulic oil temperature too high

Insufficient hydraulic oil

Refer to "6.16.1

PRE-OPERATION

INSPECTION" on P. 6-27 and

replenish the hydraulic oil to the

specified level.

Fan belt looseness

Refer to "6.17.5

MAINTENANCE EVERY 250

HOURS" on P. 6-54 and adjust

the tension or replace (★).

Oil cooler fin clogging

Refer to "6.17.5

MAINTENANCE EVERY 250

HOURS" on P. 6-54 and clean.

Crawler tracks detach.

Crawler tracks too loose

Refer to "6.18 IRREGULAR

MAINTENANCE" on P. 6-75

and adjust the tension.

Abnormal wear on the sprockets

Loading...

Loading...