6.18 IRREGULAR MAINTENANCE M A E D A Crawler Crane

6-88 5/2020 CC1908S-1

[2] Reducing tension

WARNING

• Do not loosen the plug (1) by more than one

turn. Loosening by more than one turn risks

the plug (1) flying out because the grease

inside is at high pressure.

Do not loosen any parts except the plug (1).

Also do not position your face in the

direction where the plug (1) is mounted.

• Discharging grease using procedures other

than described below is extremely

dangerous. If the crawler tracks are not

loosened, contact us or our sales service

agency for repairs.

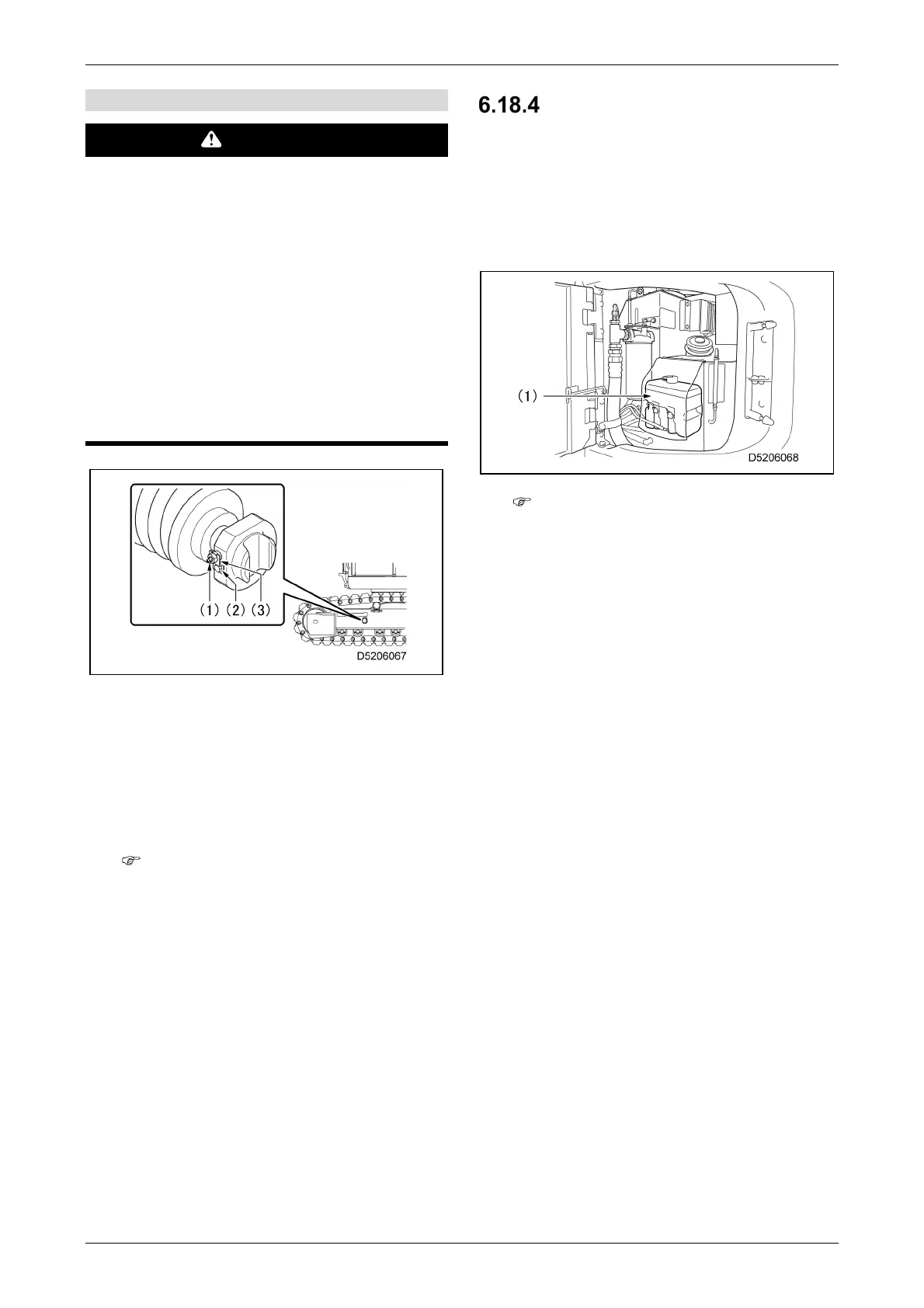

1.

Remove the bolt (2) below the plug (1).

2.

Remove the guard (3).

3.

Slowly loosen the plug (1) to discharge the

grease.

When loosening the plug (1), loosen it by only

one turn at the most.

If the grease cannot be smoothly

discharged, move the machine back and

forth slightly.

4.

Screw in plug (1).

5.

To ensure that the correct tension is applied,

keep the engine at low idle to move forward a

distance equal to the length of the crawler

tracks in contact with the ground, and then

slowly stop.

6.

Check the tension of the crawler tracks again.

If the tension is not correct, readjust.

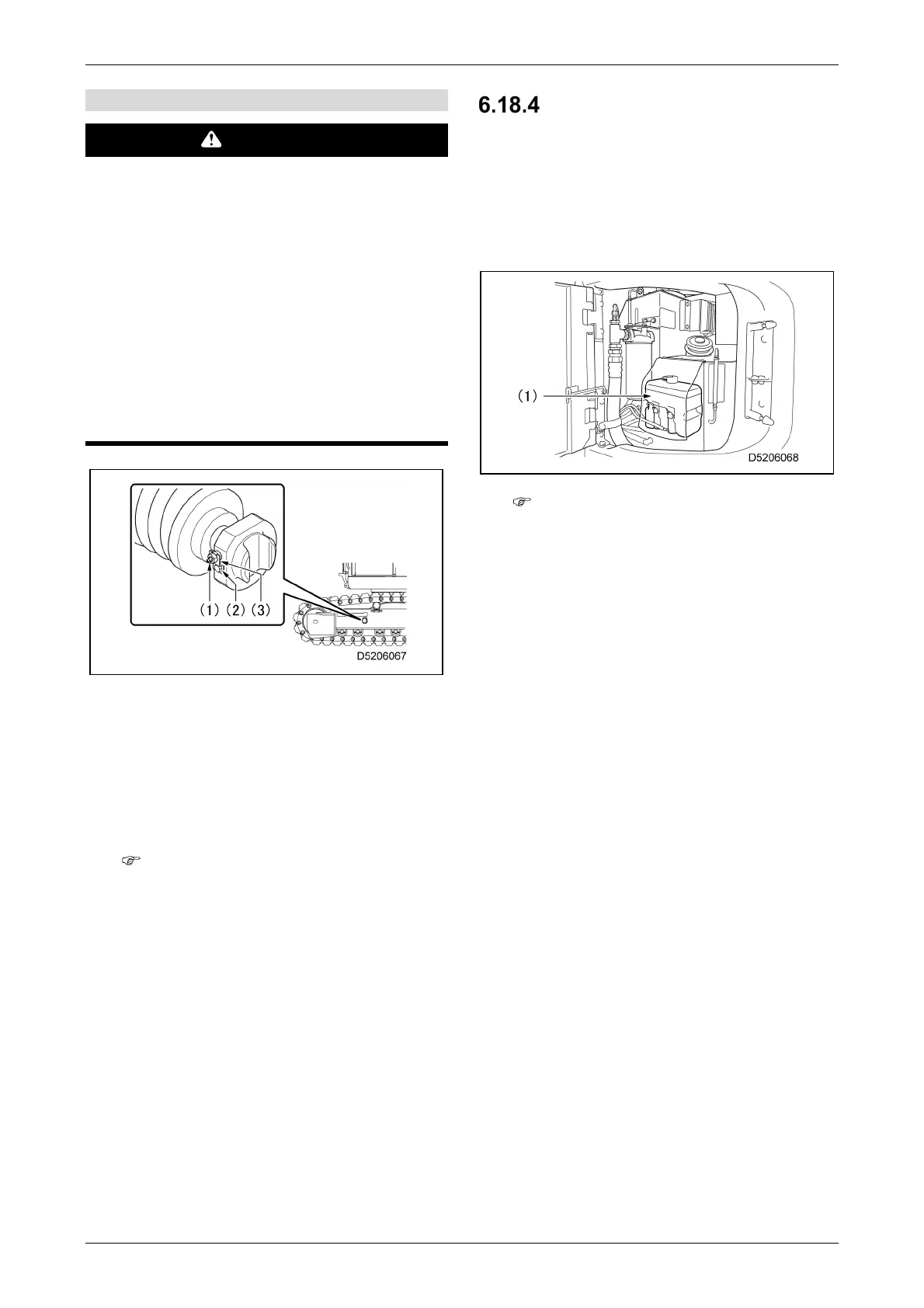

WINDOW WASHER

SOLUTION

INSPECTION/REFILLING

If air is trapped in the window washer solution,

check the level of solution in the window washer

tank (1). If it is too low, replenish with car window

washer solution.

When replenishing the window washer

solution, take care to keep it free from

dust.

The user can select one of two types provided for

different temperatures of -10 °C (for general use)

and for -30 °C (for extremely cold regions) by also

taking into account the area and season.

Loading...

Loading...