Rigging work

12.7 Rigging/unrigging the counterweight

12 - 62 3 112 xxx en Operating Manual GMK6300L

xx.xx.xxxx

12.7.6 Assembling counterweight combination

Set down 7 t (15,432 lbs) base plate

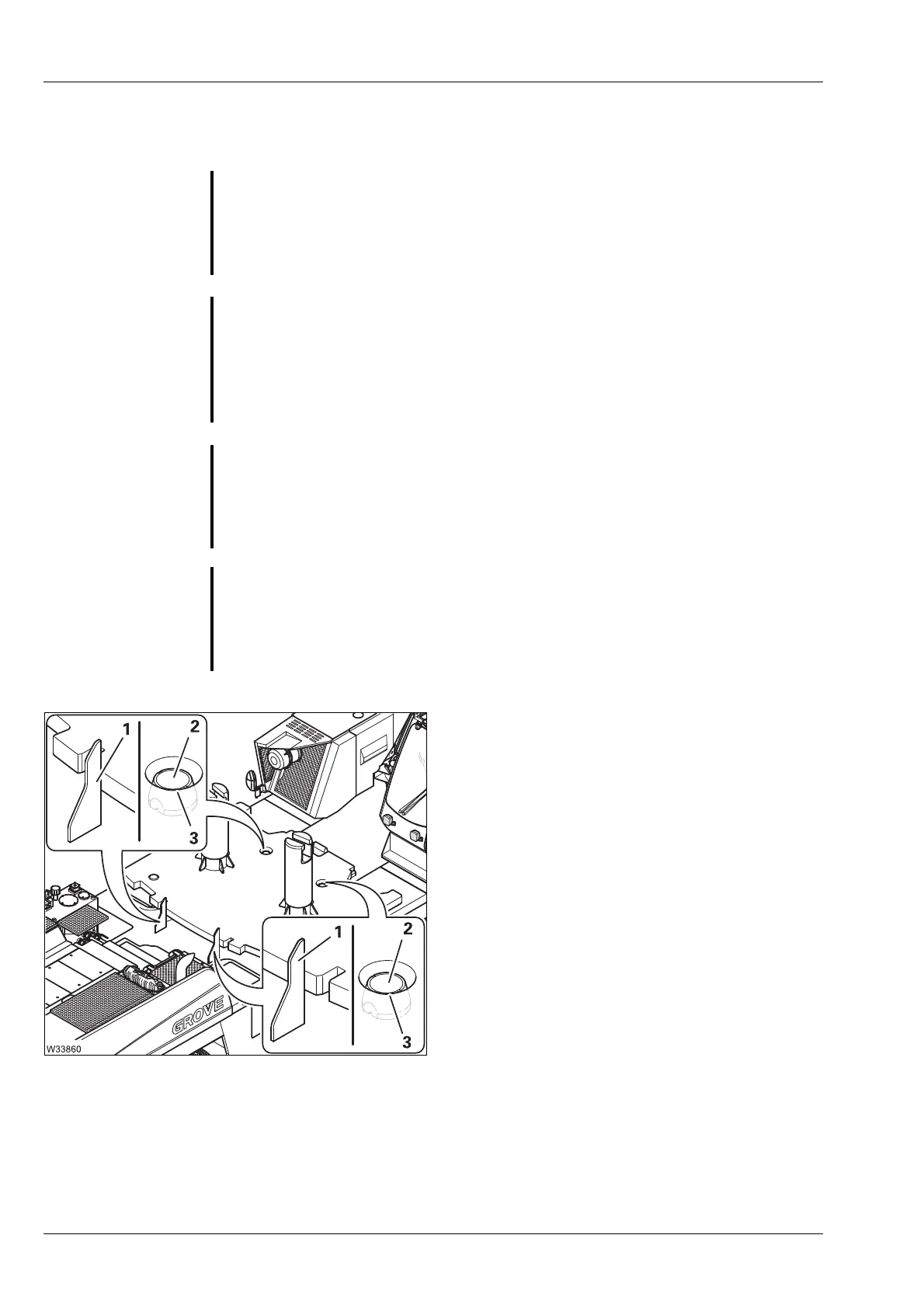

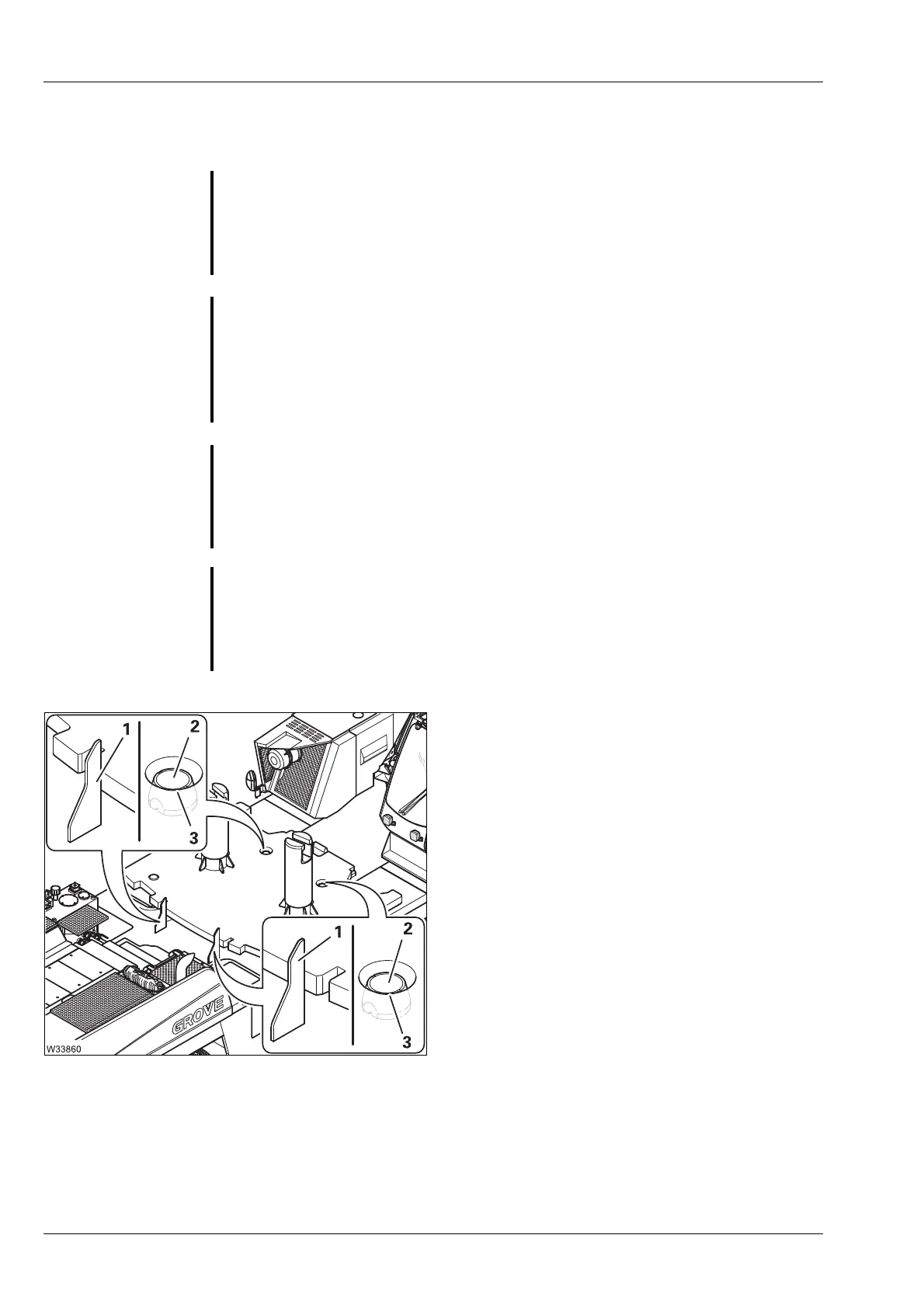

Retainers (1) and (2) are fitted to the

counterweight platform, which are used to

bring the 7 t base plate into the correct

position for rigging.

• Position the 7 t base plate in such a way that

the retainers (2) grip into cutouts (3).

For larger counterweight combinations, now

set additional counterweight sections onto

the 7 t base plate.

G

Danger of overturning when slewing with a rigged counterweight!

When a counterweight version is rigged, check whether slewing is permit-

ted with the current rigging mode (outrigger span, working radius). Correct

the rigging mode if necessary;

à Slewing with rigged counterweight,

p. 12 - 83.

G

Risk of crushing when setting down the counterweight sections!

Make sure the helpers keep a sufficient distance away from the counter-

weight sections with any parts of their body when setting down the coun-

terweight sections.

Remove all objects from the counterweight platform that could become

jammed or crushed!

G

Risk of crushing when slewing the superstructure!

Anyone who climbs onto the carrier using one of the access ladders is

within the slewing range of the superstructure.

Make sure nobody uses the access ladders (e.g. helpers) while you lift

a section onto the carrier.

G

Risk of accidents due to falling counterweight sections!

Only attach the counterweight sections to the appropriate slinging points

and use lifting gear of sufficient load bearing capacity.

The counterweight sections should be lifted only one at a time. The slinging

points are not designed for hoisting stacked counterweight sections.

Loading...

Loading...