Rigging work

12.7 Rigging/unrigging the counterweight

12 - 58 3 112 xxx en Operating Manual GMK6300L

xx.xx.xxxx

12.7.4 CHECKLIST: Rigging the counterweight

H

This checklist is not a complete operating manual. There are accompanying

instructions, which are indicated by cross-references.

Observe the warnings and safety instructions there!

1. The truck crane is stabilised with the outrigger span required for crane

work according to the

Lifting capacity table; à Permissible outrigger spans,

p. 12 - 30.

2. Enter the current rigging mode on the RCL;

à p. 11 - 23.

3. When the 3-sheave hook block is reeved:

– extend telescopic section VI by 50%.

4. Assemble the required combination of counterweights:

– Lower 7.0 t base plate on the counterweight platform;

à p. 12 - 64.

– Lift the counterweight sections individually, one after another;

à p. 12 - 62.

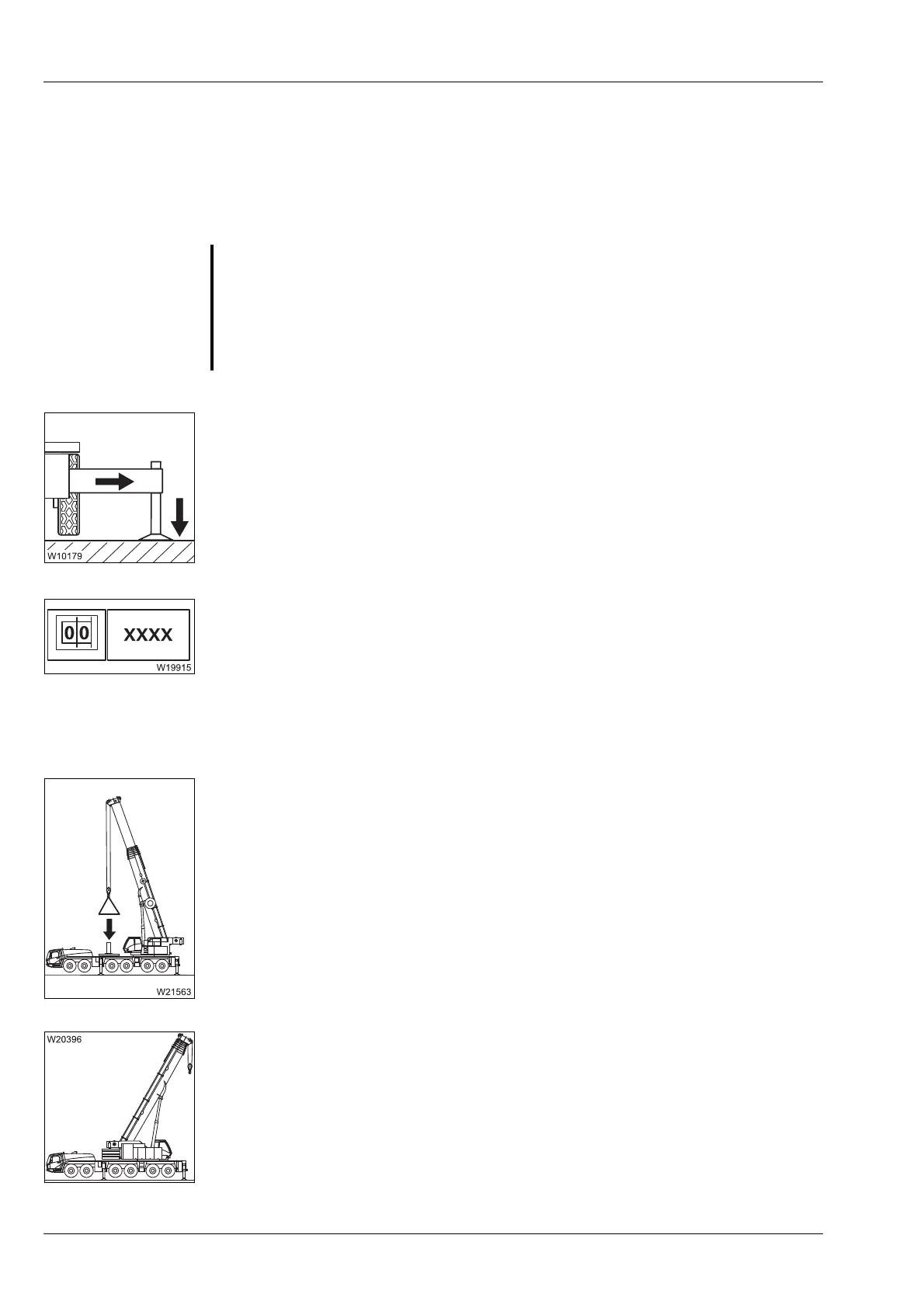

5. Slew the superstructure into the

0° to the rear position; à Braking the

slewing movement

, p. 11 - 99.

G

Danger of overturning when slewing with a rigged counterweight!

Always check before slewing whether slewing is permitted in the truck

crane's current rigging mode (counterweight, outrigger span, working

radius).

Correct the rigging mode if necessary;

à Slewing with rigged counterweight,

p. 12 - 83.

Loading...

Loading...