6-23

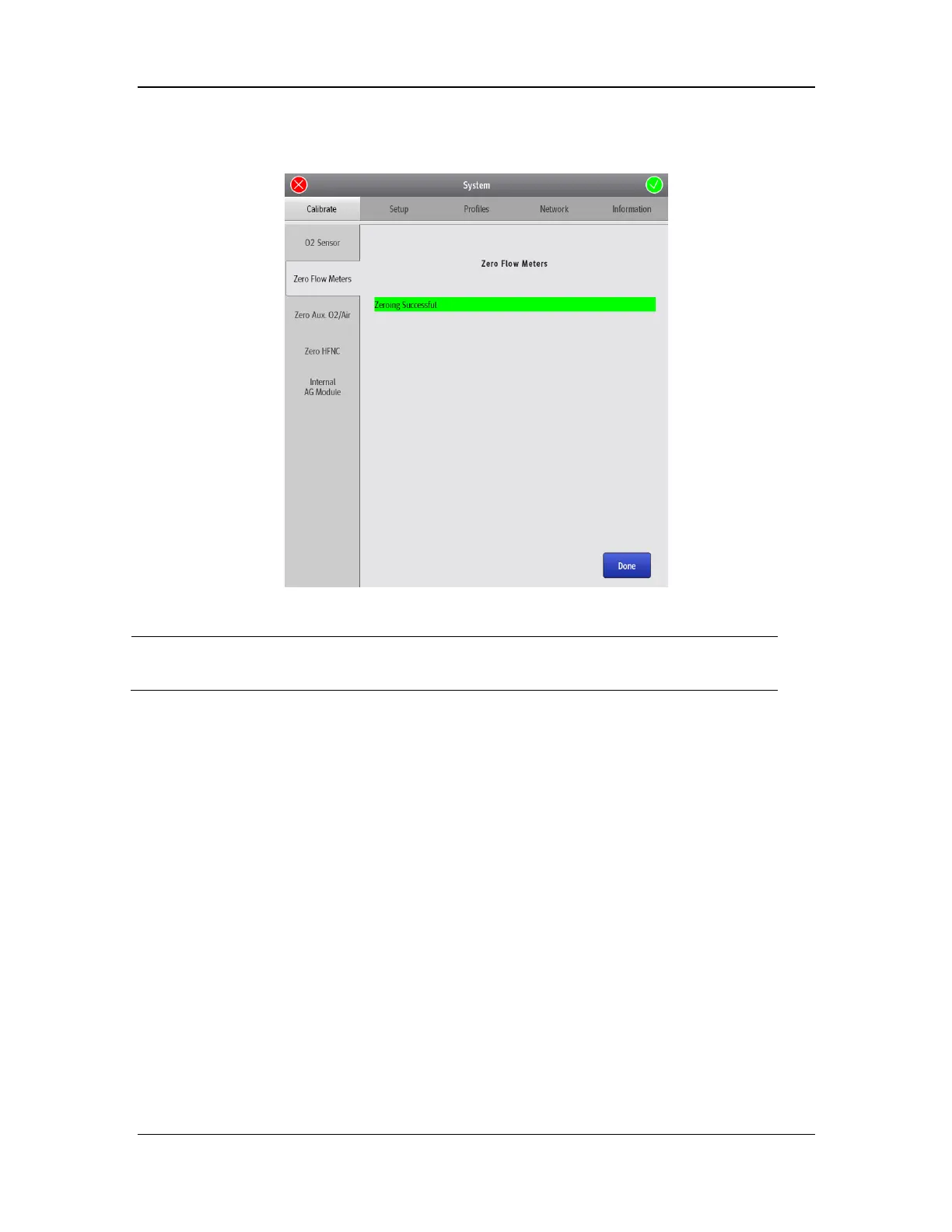

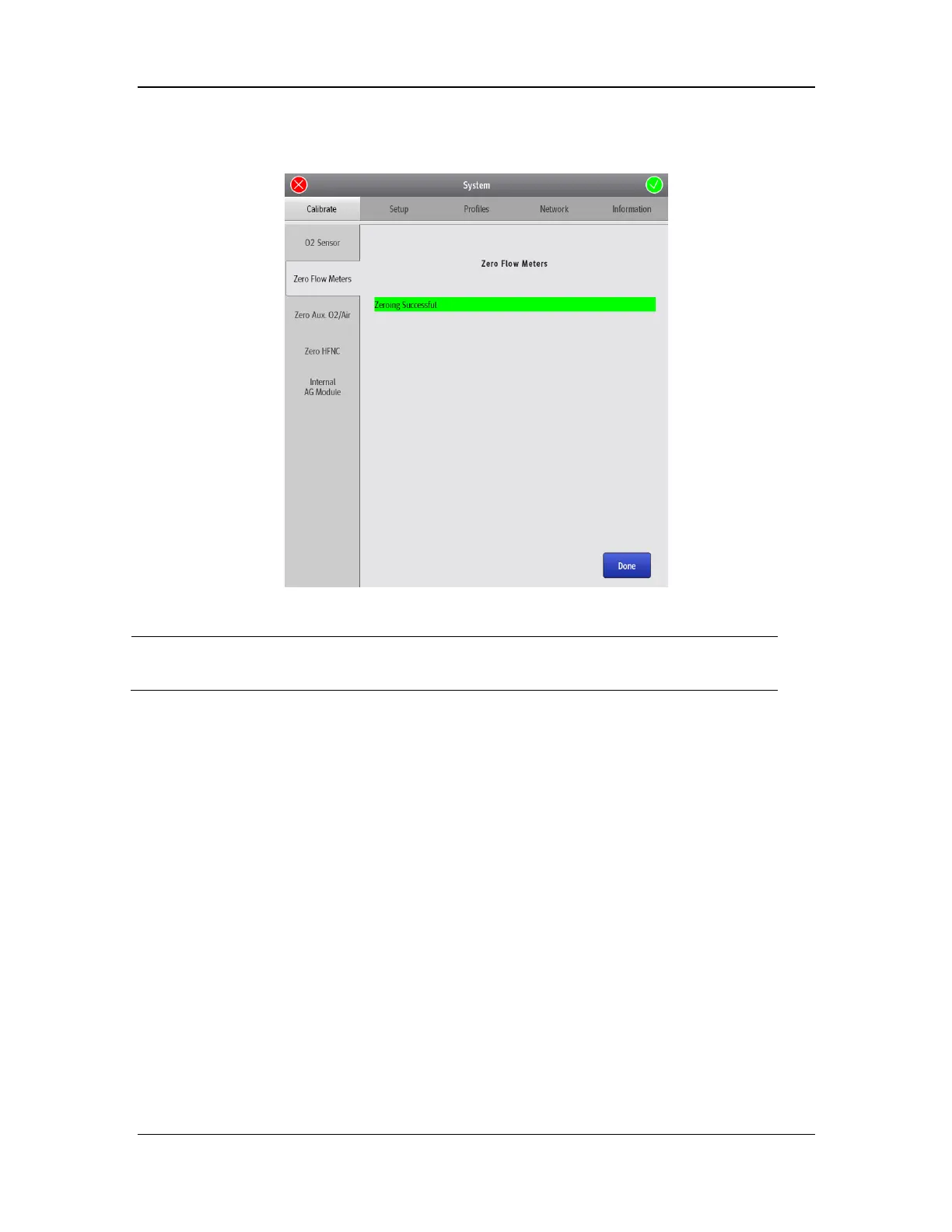

5.The screen shown below is displayed upon successful zeroing. Select Done to exit the zeroing

screen.

Other faults may exist in the EFCS if the zeroing fails. You must locate and

rectify the faults.

6.3.3.3 Zeroing Failure Troubleshooting

If the zeroing fails, perform the following steps to locate and rectify the fault.

1. Disconnect the gas supplies, adjust the flowmeter for the pointer of the pressure gauge to

return to zero, and then perform zeroing again.

2. If the zeroing is successful, it is concluded that the previous zeroing failure is caused by a

mechanical failure in the three-way valve or faults in the proportional valves. Replace the

service parts of the EFCS.

3. If the zeroing still fails, replace the EFCS flowmeter sensor or board.

6.3.4 High-flow O2 Supply Zeroing (User)

6.3.4.1 Principles

The principles are as follows: Close the pilot valve and the air and O2 branch proportional valves

when starting zeroing. Read the AD values measured by the Sensirion differential pressure

sensors in the two branches and use them as zero points of the two branch differential pressure

sensors.

6.3.4.2 Zeroing Procedure

Perform the following steps to zero the high-flow O2 supply assembly.

Loading...

Loading...