2-67

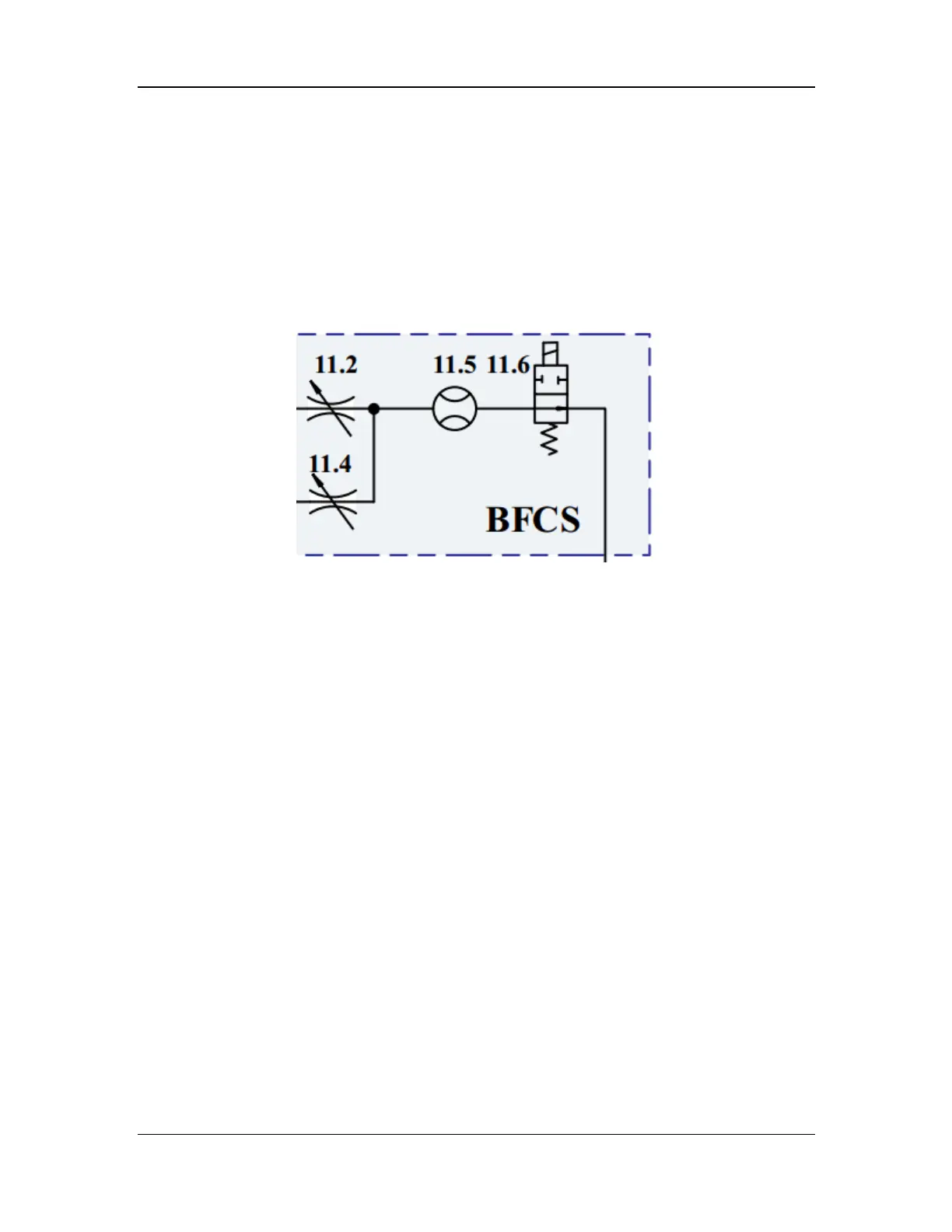

2.3.3.2 BFCS Assembly

The BFCS assembly is used in case of system failure or EFCS assembly failure resulting from

power failure. The BFCS contains two branches: air branch and O2 branch, which are separately

controlled by two needle valves. The gas is supplied by the system switch assembly. The rear

ends of the air needle valve (11.4) and O2 needle valve (11.2) are joined and connected to the

backup flowmeter (11.5), which is a mechanical float flowmeter for indicating the current flow.

The downstream is connected to the EFCS assembly through an NO switch valve (11.6), which is

powered on and closed during normal operation. When the BFCS assembly is activated, the valve

is powered off and automatically open for ventilation. The backup flowmeter is configured with a

backlight board on the rear, which emits light after the BFCS assembly is activated. The

pneumatic diagram of the BFCS assembly is shown below.

Figure 15 Pneumatic diagram of the BFCS assembly

2.3.4 Vaporizer Subsystem

The vaporizer subsystem is mainly used to provide the patient with anesthetic gas at certain

concentration. Different vaporizer subsystems are configured for the A8 and A9 anesthesia

machines. The vaporizer subsystem of the A8 anesthesia machine consists of a mechanical

vaporizer and a mechanical vaporizer manifold assembly. The vaporizer subsystem of the A9

anesthesia machine consists of an electronic vaporizer and an electronic vaporizer manifold

assembly.

2.3.4.1 Mechanical Vaporizer Manifold Assembly (for A8)

The mechanical vaporizer manifold assembly provides a mounting location for the mechanical

vaporizer (installation mode: Selectatec), mixes the anesthetic gas with the O2/air mixture at the

input end to form fresh gas, and delivers the fresh gas to the common gas outlet. The assembly

contains two connectors: one gas inlet connected to the EFCS assembly outlet, and one common

gas outlet serving as an inlet of the ACGO assembly.

In principle, the mechanical vaporizer manifold assembly is a combination of a series of

two-position three-way valves, which are controlled by the springs and vaporizer. When the

vaporizer is not installed, the valves are in a certain state due to the spring force, and the

mechanical vaporizer manifold assembly is a path. When the vaporizer is installed, the status of

the two-position three-way valves switches to make the gas flow through the vaporizer. The

pneumatic diagram is shown below.

Loading...

Loading...