6-27

6.3.5 Pressure Calibration (Service)

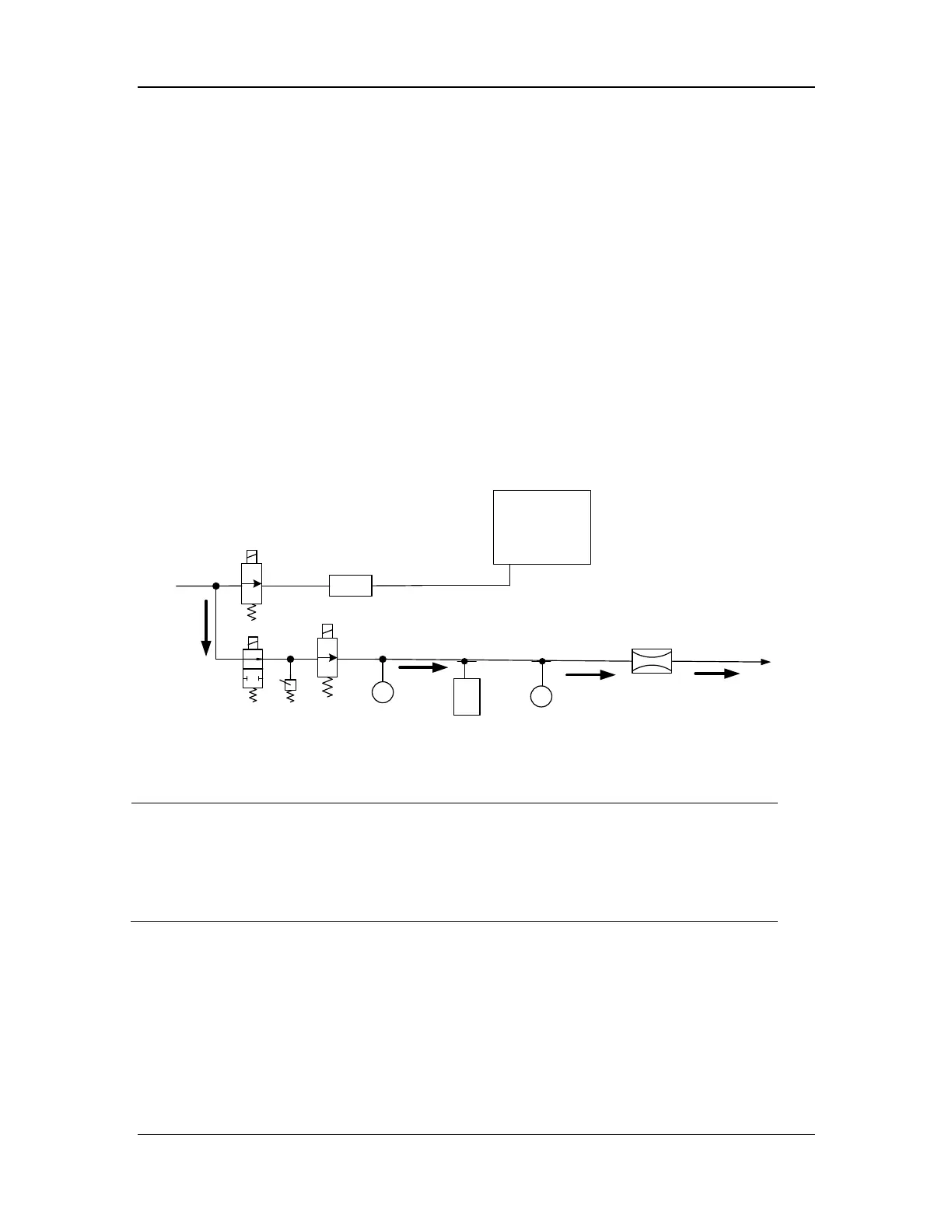

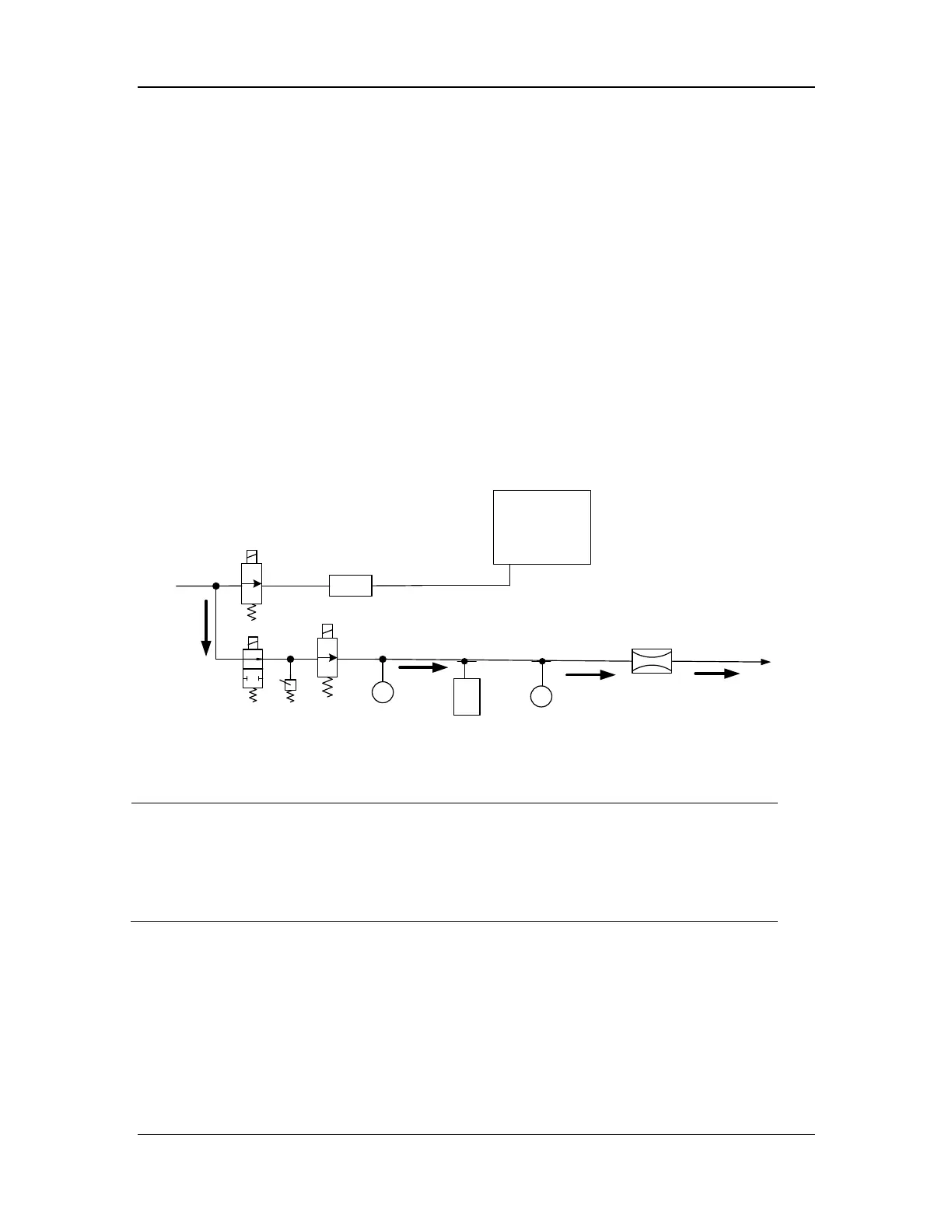

6.3.5.1 Principles

In pressure calibration (service), the anesthesia machine calibration device (for example, VT900,

VT650, TSI Certifier) specified by the manufacturer needs to be used to calibrate the PEEP valve,

Paw sensor, and PEEP pressure sensor. The calibration principles are as follows: The anesthesia

machine calibration device can communicate with the VCM, which controls the tight closing of

the inspiratory valve. The VCM opens the PEEP valve based on a certain DA value to make the

circuit pressure reach a certain value. The Paw sensor, PEEP pressure sensor, and anesthesia

machine calibration device collect the circuit pressure. The calibration device sends the collected

pressure to the VCM. The VCM uses the pressure measured by the calibration device and AD

values collected by the pressure sensors as the data of one calibration point for the pressure

sensors, and uses the pressure measured by the calibration device and DA value of the PEEP

valve as the data of one calibration point for the PEEP valve. The VCM controls the PEEP valve

to change the DA value to obtain calibration data under a series of pressures, forming a pressure

calibration data table. The gas pressure should be in the range from 0 cmH2O to 100 cmH2O

when the VCM opens the PEEP valve.

Figure 1 Schematic diagram of pressure calibration (service)

Flow

Inspiratory valve

Ventilator flow

sensor

PEEP valve

PEEP safety valve

P

PEEP sensor

Pneumatic resistor

Calibration device

P

Paw sensor

6.3.5.2 Precautions

Pressure calibration (service) needs to be performed if the sensor adapter board,

VCM, or expiratory valve assembly is replaced.

Pressure calibration (service) needs to be performed if the measured value of the

built-in pressure sensor deviates from that of the standard pressure measuring

device by 5% or 2 cmH2O, whichever is larger .

Loading...

Loading...