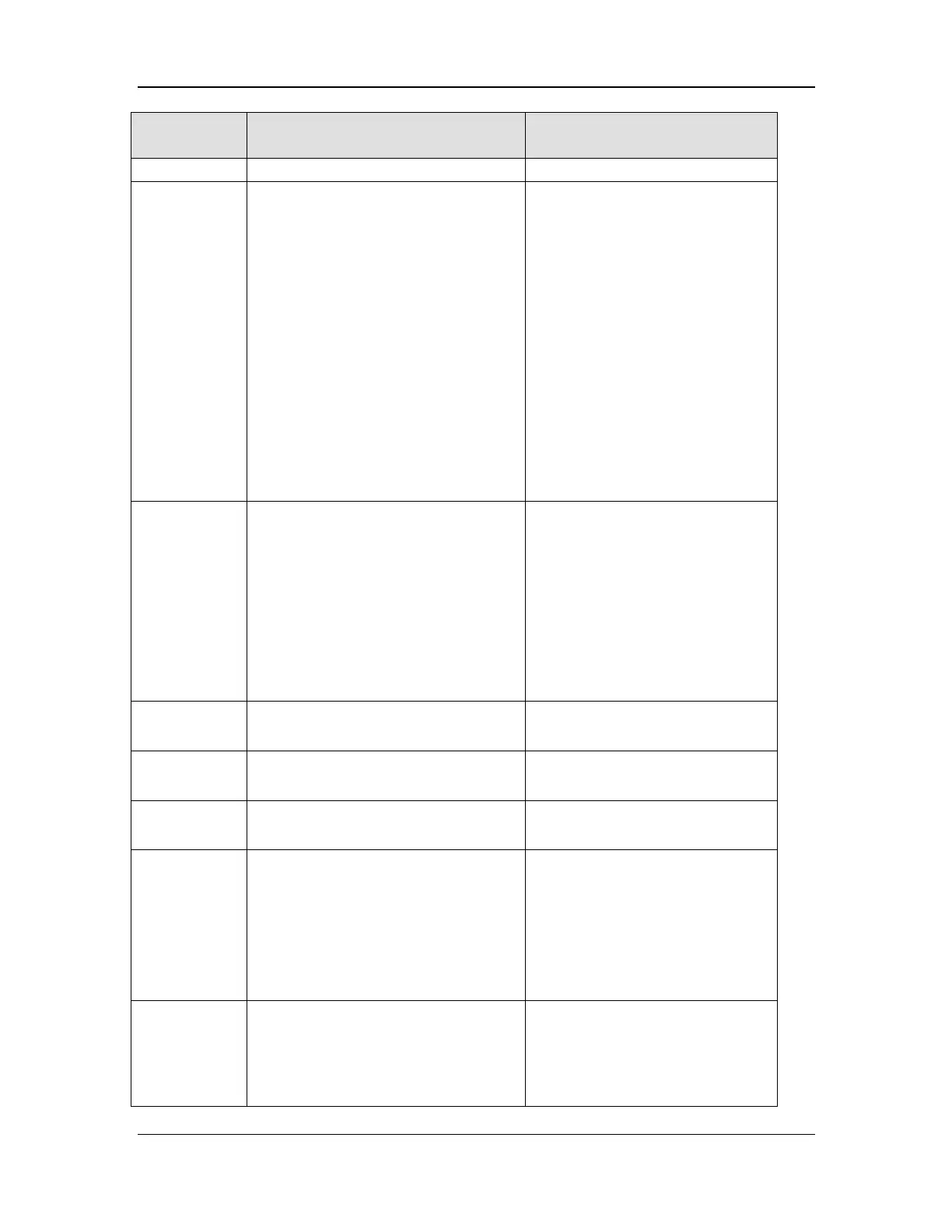

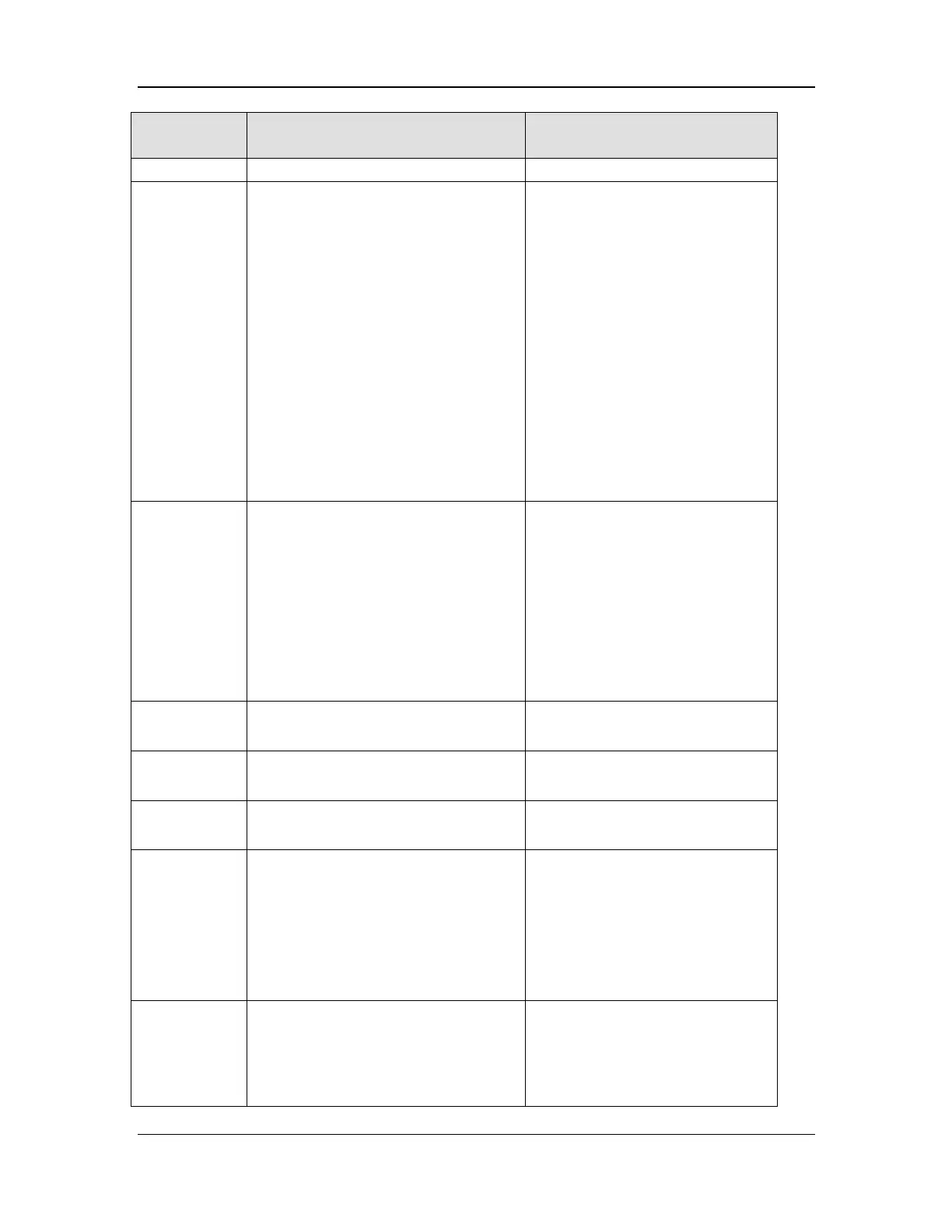

6-38

Failure

Description

Possible Cause Recommended Action

2. Replace the PEEP valve.

Display 4

The pressure cannot be controlled

within the range of [maximum pressure

– 20, maximum pressure – 5] cmH2O.

1.

Use the valve diagnosis tool

for diagnosis. (1) Open the

PEEP valve based on 500 mA.

The pressure measured by the

calibration device is greater

than or equal to 100 cmH2O.

(2) Close the PEEP valve and

increase the opening of the

PEEP valve based on a certain

current. The AD values

collected by the Paw sensor

increase gradually.

Recalibration is

recommended if the preceding

conditions are met.

2. Replace the PEEP valve.

Display 5 The maximum valve sealing pressure is

low.

1. Check whether the gas supply

is within the range of 280–600

kPa (40 psi–87 psi) for the

whole calibration process.

2. Use the valve diagnosis tool to

check whether the maximum

output pressure of the PEEP

valve is greater than or equal

to 100 cmH2O. If not, replace

the drive gas assembly.

Display 6

A zero point error occurs in the Paw

sensor.

1. Zero the sensor.

2. Replace the VCM.

Display 7 A zero point error occurs in the PEEP

sensor.

1. Zero the sensor.

2. Replace the VCM.

Display 8

A zero point error occurs in the

esophageal pressure sensor.

1. Zero the sensor.

2. Replace the VCM.

Display A The calibration data of the Paw sensor

does not conform to monotonicity (the

AD value of t

he former calibration

point is greater than that of the latter

calibration point).

1. Check the pipeline connection

and the gas tightness.

2. Check whether the gas supply

pressure ranges from 280 kPa

to 600 kPa (40 psi–87 psi).

3. Perform the calibration again.

4. Replace the VCM.

Display B The calibration data of the PEEP sensor

does not conform to monotonicity (the

AD value of the former calibration

point is greater than that of the latter

calibration point).

1. Check the pipeline connection

and the gas tightness.

2. Check whether the gas supply

pressure ranges from 280 kPa

to 600 kPa (40 psi–87 psi).

Loading...

Loading...