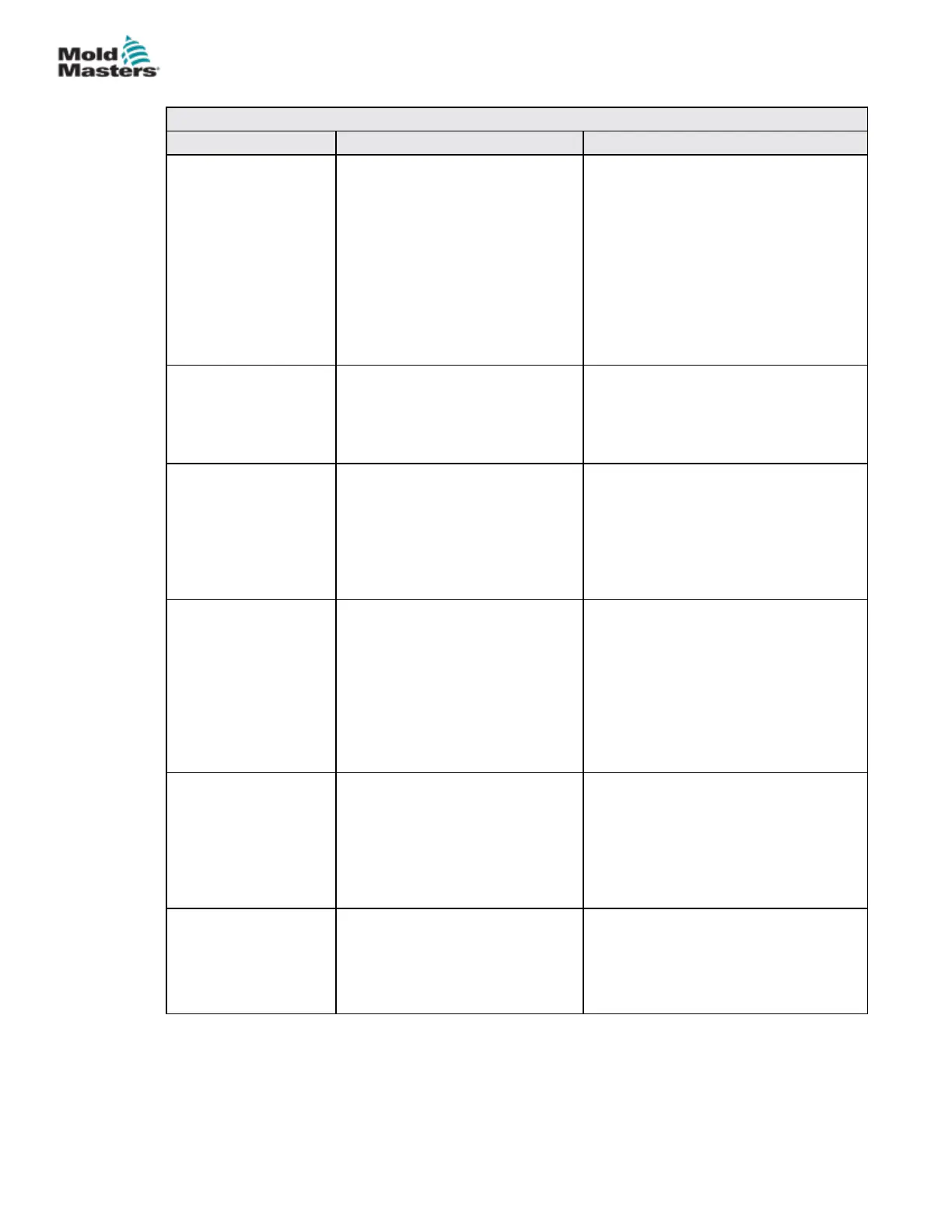

3.7.1 Energy Forms and Lockout Guidelines

Table 3-3 Energy Forms, Energy Sources and General Lockout Guidelines

Energy Form Energy Source Lockout Guidelines

Electrical Energy • Power transmission lines

• Machine power cords

• Motors

• Solenoids

• Capacitors

(stored electrical energy)

• Turn o power at machine rst (i.e.,

at point of operation switch), and

then at the main disconnect switch

for the machine.

• Lock and tag the main disconnect

switch.

• Fully discharge all capacitative

systems (e.g., cycle machine

to drain power from capacitors)

according to the manufacturer’s

instructions.

Hydraulic Energy • Hydraulic systems

(e.g., hydraulic presses,

rams, cylinders, hammers)

• Shut o, lock (with chains, built-

in lockout devices, or lockout

attachments) and tag valves.

• Bleed o and blank lines as

necessary.

Pneumatic Energy • Pneumatic systems

(e.g.,lines, pressure

reservoirs, accumulators, air

surge tanks, rams, cylinders)

• Shut o, lock (with chains, built-

in lockout devices, or lockout

attachments) and tag valves.

• Bleed o excess air.

• If pressure cannot be relieved,

block any possible movement of

machinery.

Kinetic Energy

(Energy of a moving

object or materials.

Moving object may

be powered or

coasting)

• Blades

• Flywheels

• Materials in supply lines

• Stop and block machine parts (e.g.

stop ywheels and ensure that they

do not recycle).

• Review entire cycle of mechanical

motion, ensure that all motions are

stopped.

• Block material from moving into

area of work.

• Blank as necessary.

Potential Energy

(Stored energy that

an object has the

potential to release

due to its position)

• Springs

(e.g., in air brake cylinders)

Actuators

• Counterweights

• Raised loads

• Top or movable part of a

press or lifting device

• If possible, lower all suspended

parts and loads to the lowest (rest)

position.

• Block parts that might be moved by

gravity.

• Release or block spring energy.

Thermal Energy • Supply lines

• Storage tanks and vessels

• Shut o, lock (with chains, built-

in lockout devices, or lockout

attachments) and tag valves.

• Bleed o excess liquids or gases.

• Blank lines as necessary.

3-11

© 2020 Mold-Masters (2007) Limited. All Rights Reserved.

SAFETY

MT Controller User Manual

Loading...

Loading...