5.4 Change Zone PID Characteristics

On initial startup, each module CPU reads the zone heater characteristic and

determines an appropriate PID curve for that zone. It is possible for the user

to override this setting and change the zone response time for any zone.

In general, a small nozzle works best on a “Fast” setting, a larger manifold

uses a “Med(ium)” setting and a really large heating platen may require a

“Slow” setting. If you are having problems matching a zone then consult your

local dealer for service advice.

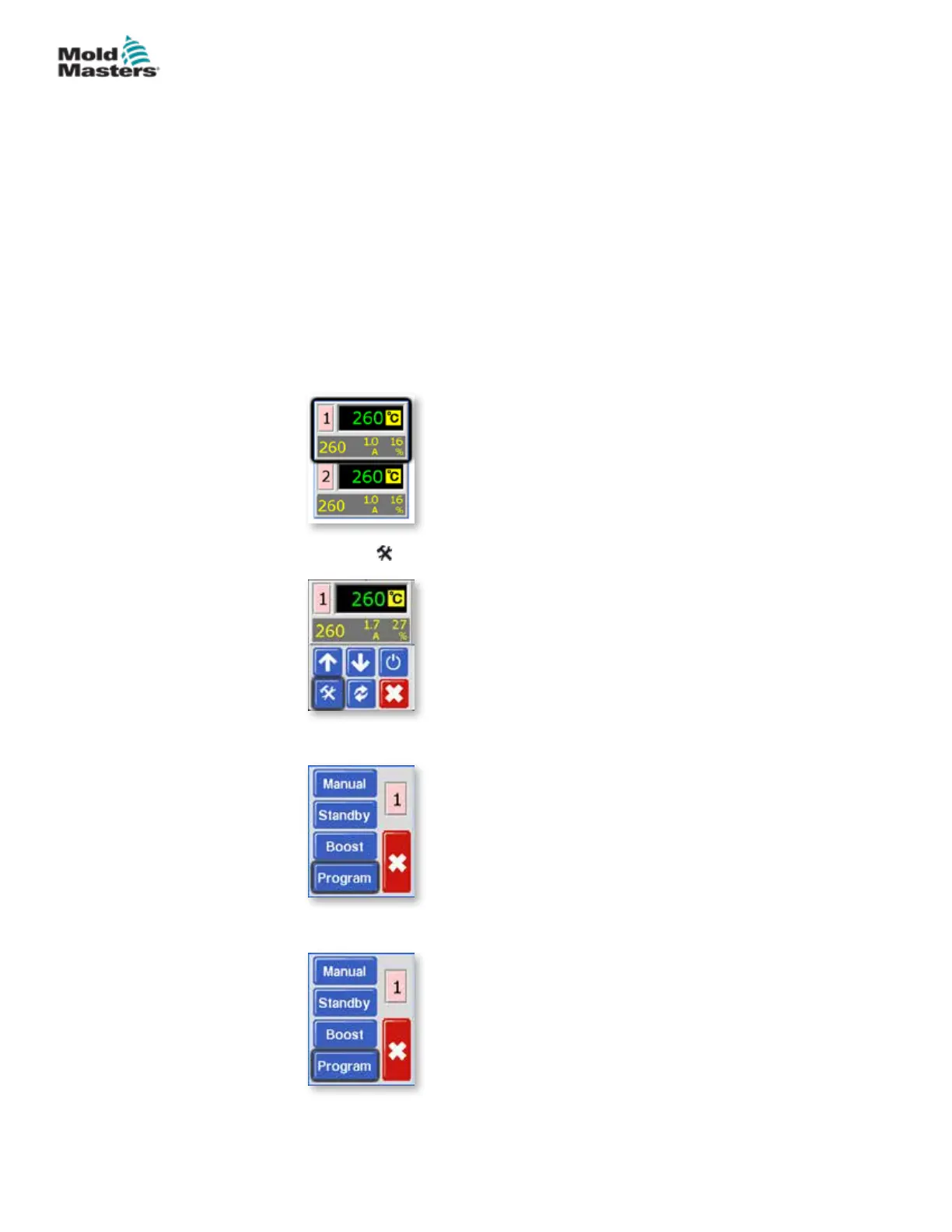

Once the controller has run and the PID curve has been selected, the screen

will display the selected speed with a blue ring. See step ve in the following

procedure to see an example of this blue ring.

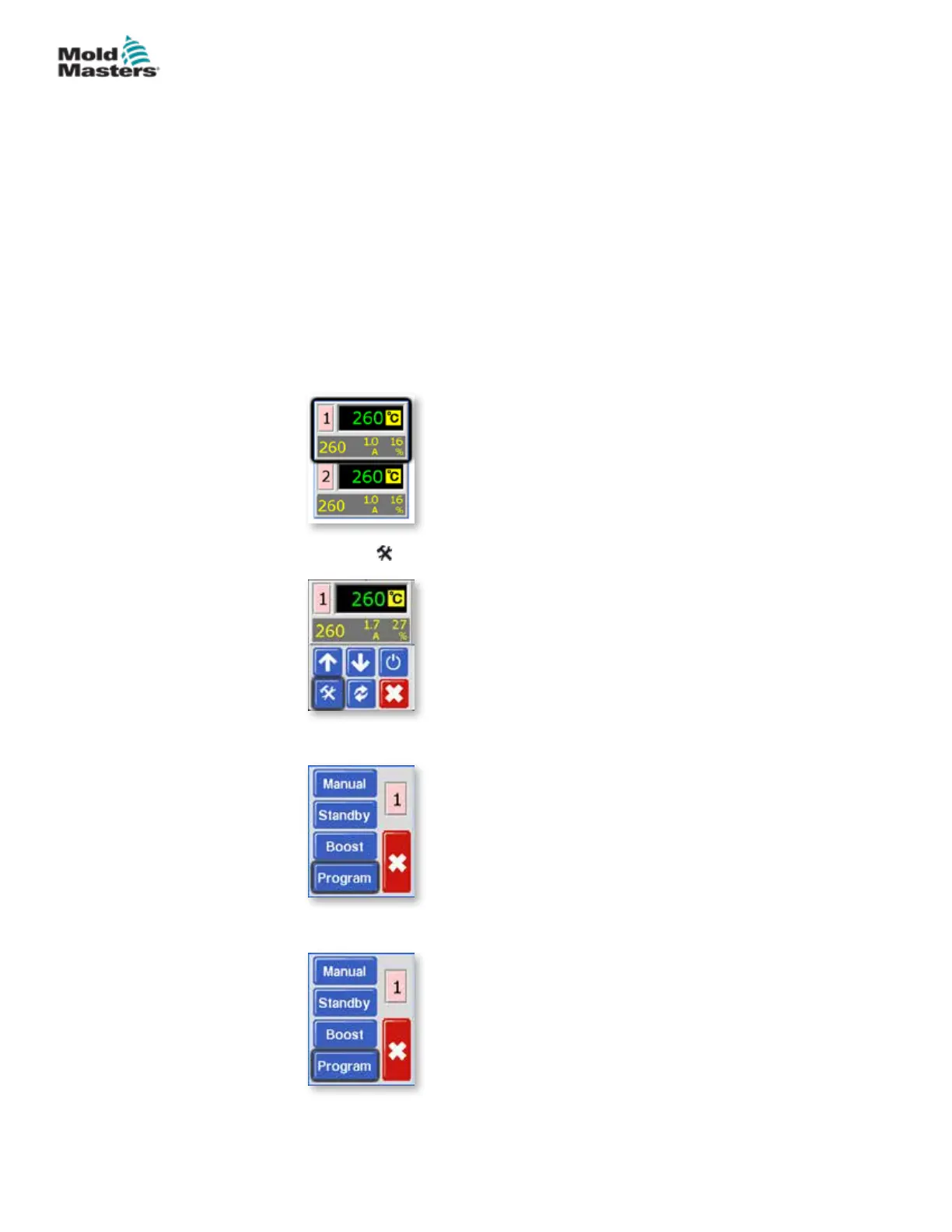

1. From the Temperature Display screen, choose either zone to obtain the

initial menu.

2. Choose [ ] to obtain the Function menu.

3. Choose [Program] to obtain the Program menu.

4. Choose [] or [] to nd the page containing the PID option.

5-7

© 2020 Mold-Masters (2007) Limited. All Rights Reserved.

SETUP

MT Controller User Manual

Loading...

Loading...