Y100250-48-8

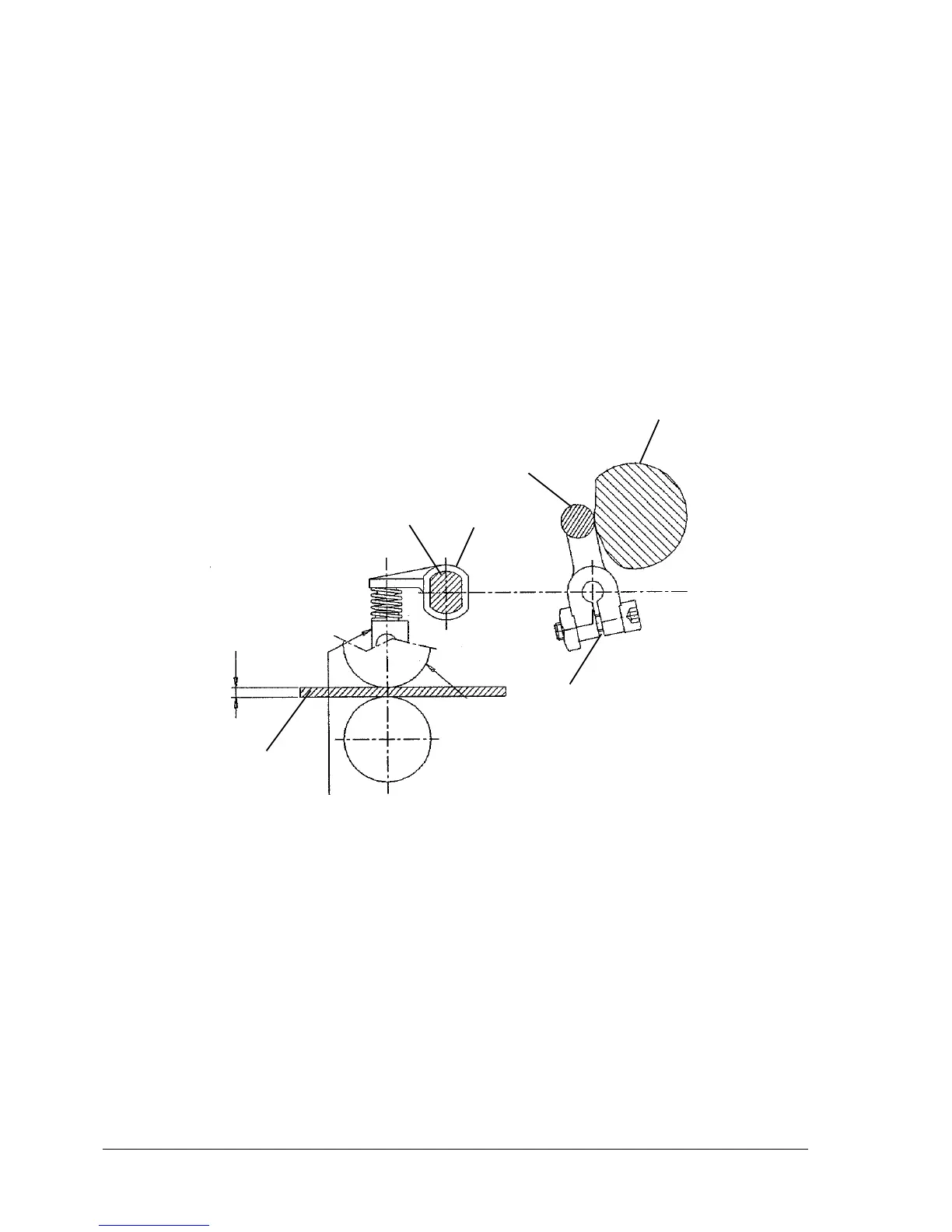

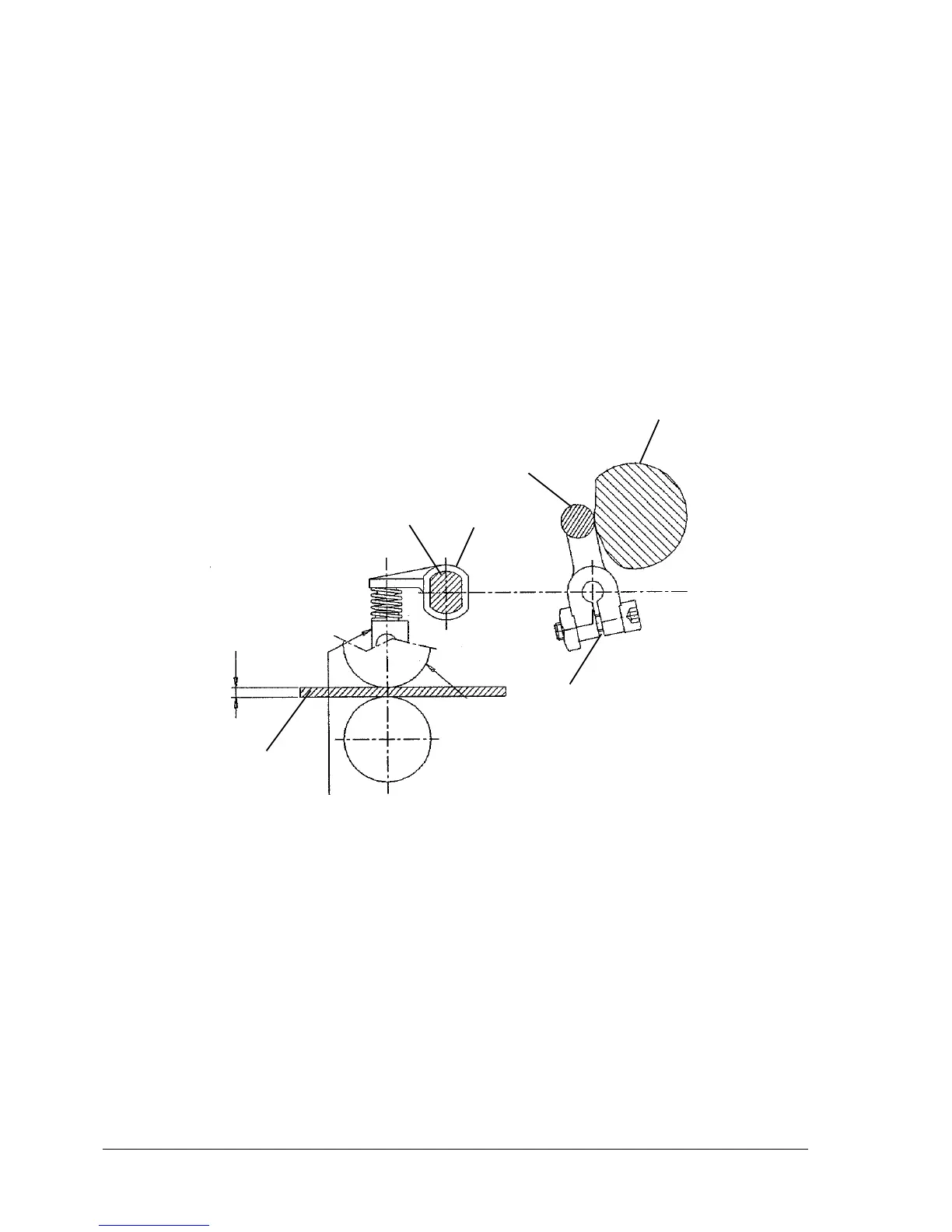

8.7 FRONT PRESSURE ROLLER ADJUSTMENT

MACHINE CONDITION:

Service cam with its minimum throw area facing the probe roller.

OBJECTIVE ADJUSTMENT:

Make sure that there is a small clearance between the probe roller (7) and the service cam (6).

(To check the correctness of the adjustment remove the probe and, without changing the fase, check

for a slight clearance between the roller and cam without loading the springs. There must be no

clearance when the probe is inserted again).

PROCEDURE:

Insert an 0.5 mm thick probe (1) between the pressure rollers (5) and the feed rollers (8); by acting on

shaft (2), position the three levers (3) so that they come into contact with the springs and then tighten

screws (4) with a torque of 20 Kgcm while holding the roller against the cam's smallest radius.

Fig. 8-7

Note: The adjustment value can vary for certain non-standard products.

6

7

3

2

4

5

1

0,5

Loading...

Loading...