Examples and tips

PROGRAMMING MANUAL 247

Revision 3.0

The smallest integer m for which this equation is valid is 8203. This

results in Pn205 = 8202.

In addition, to limit the motion units range to the moving range of

the motion part, the following axis parameters must be set:

REP_DIST = 4260, and REP_OPTION = 1. With these settings,

executing MOVE(38) moves the moving part 38 mm in forward

direction. The range of possible MPOS and DPOS values is 0 mm

to 4160 mm.

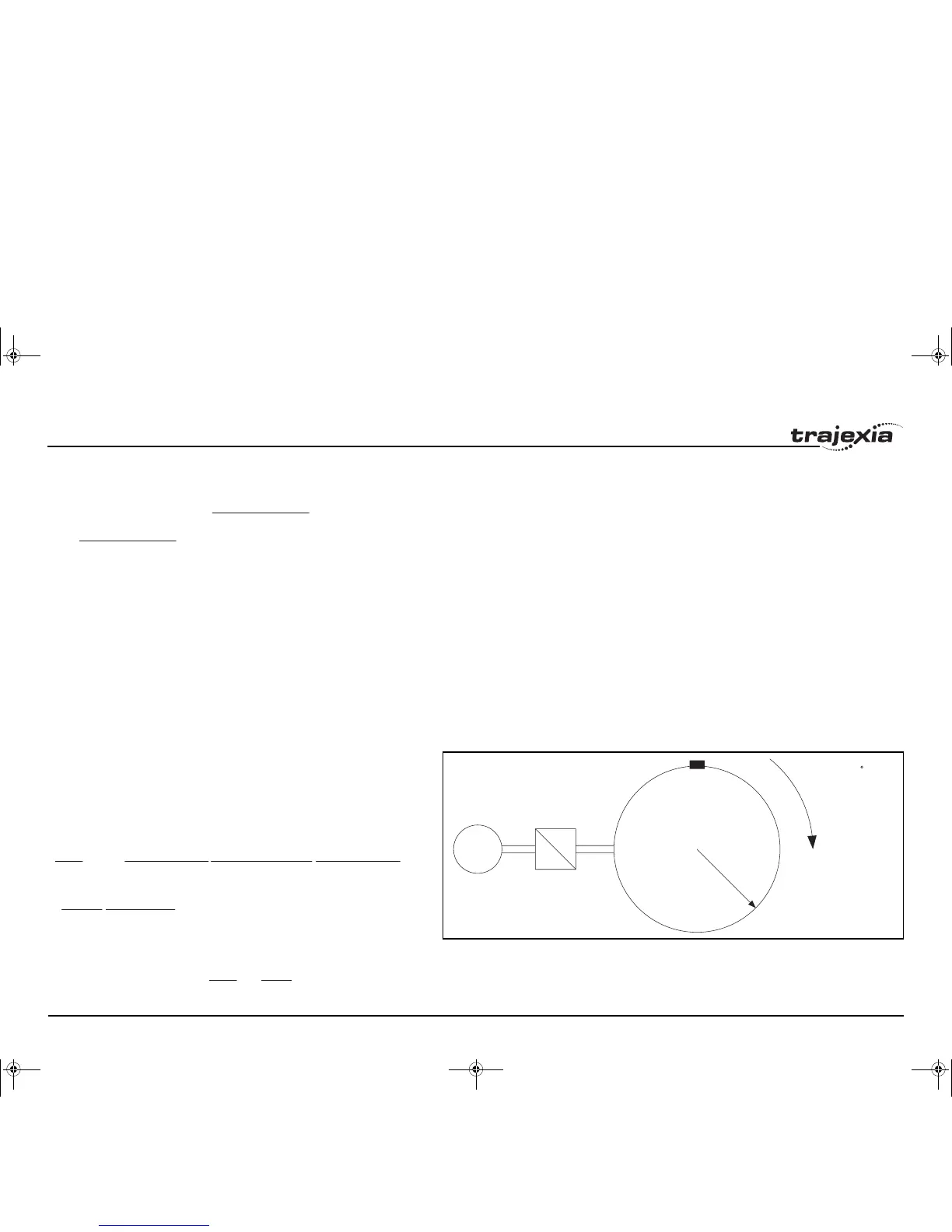

Example 4

fig. 22

The mechanical system uses a servo motor with a 17-bit absolute

encoder. The mechanical gear ratio of the gearbox is 1:12.24. The

mechanical measurement units must be tenths of an angle degree.

Therefore the total repeat distance for the full turn of the moving

part is 3600 tenths of an angle degree.

With the same procedure as in example 1, we have:

Therefore:

m motor_revolution = n machine_cycle

m motor_revolution = n machine_cycle

4160 pulley_revolution

320 machine_cycle

= n 13 pulley_revolution

= n 13

6 31 motor_revolution

1 pulley_revolution

= n 82.03 pulley_revolution

m = n 82.03

..

....

.

.

...

.

.

1:12.24 Gear

17-bit absolute

encoder

M

r

Full turn = 360 =

3600 x tenth of degree

Pn202

Pn203

UNITS =

2

17

encoder_counts

1 motor_revolution

1 machine_revolution

12.24 motor_revolution

3600 tenth of degree

1 pulley_revolution

3600

2 12.24

encoder_counts

=

tenth of degree

=

.

.

.

..

.

17

Pn202

Pn203

UNITS =

= 2

1224

360000

17

I52E-EN-03.book Seite 247 Freitag, 29. Juni 2007 11:55 11

Loading...

Loading...