BASIC commands

PROGRAMMING MANUAL 33

Revision 3.0

3 BASIC commands

3.1 Categories

This section lists all BASIC commands divided by categories. The categories

are:

• Axis commands.

• Axis parameters.

• Communication commands and parameters.

• Constants.

• I/O commands, functions and parameters.

• Mathematical functions and operations.

• Program commands.

• Program control commands.

• Slot parameters and modifiers.

• System commands and functions.

• System parameters.

• Task commands and parameters.

The lists are quick reference guides only. A complete description of the

commands is given in alphabetical order in the next section.

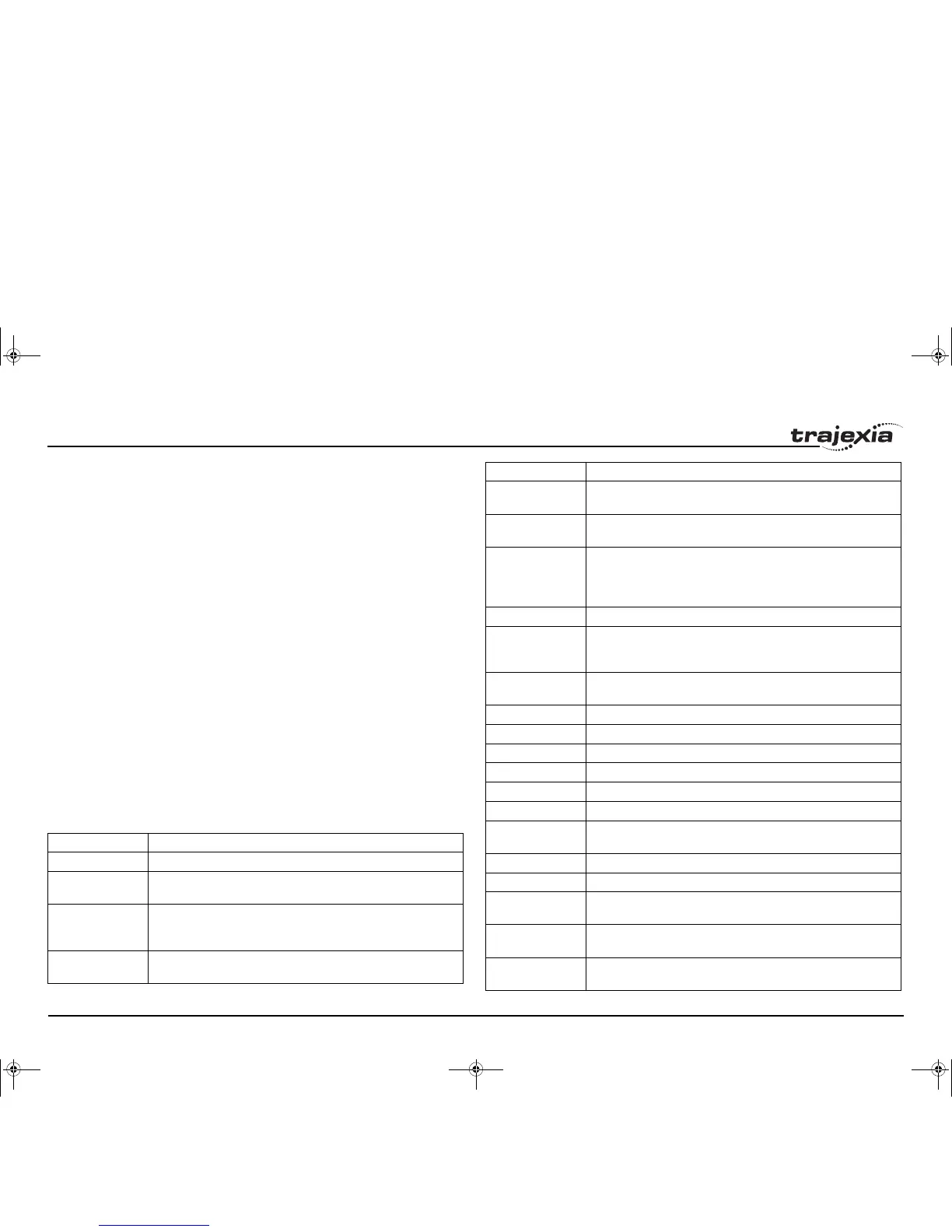

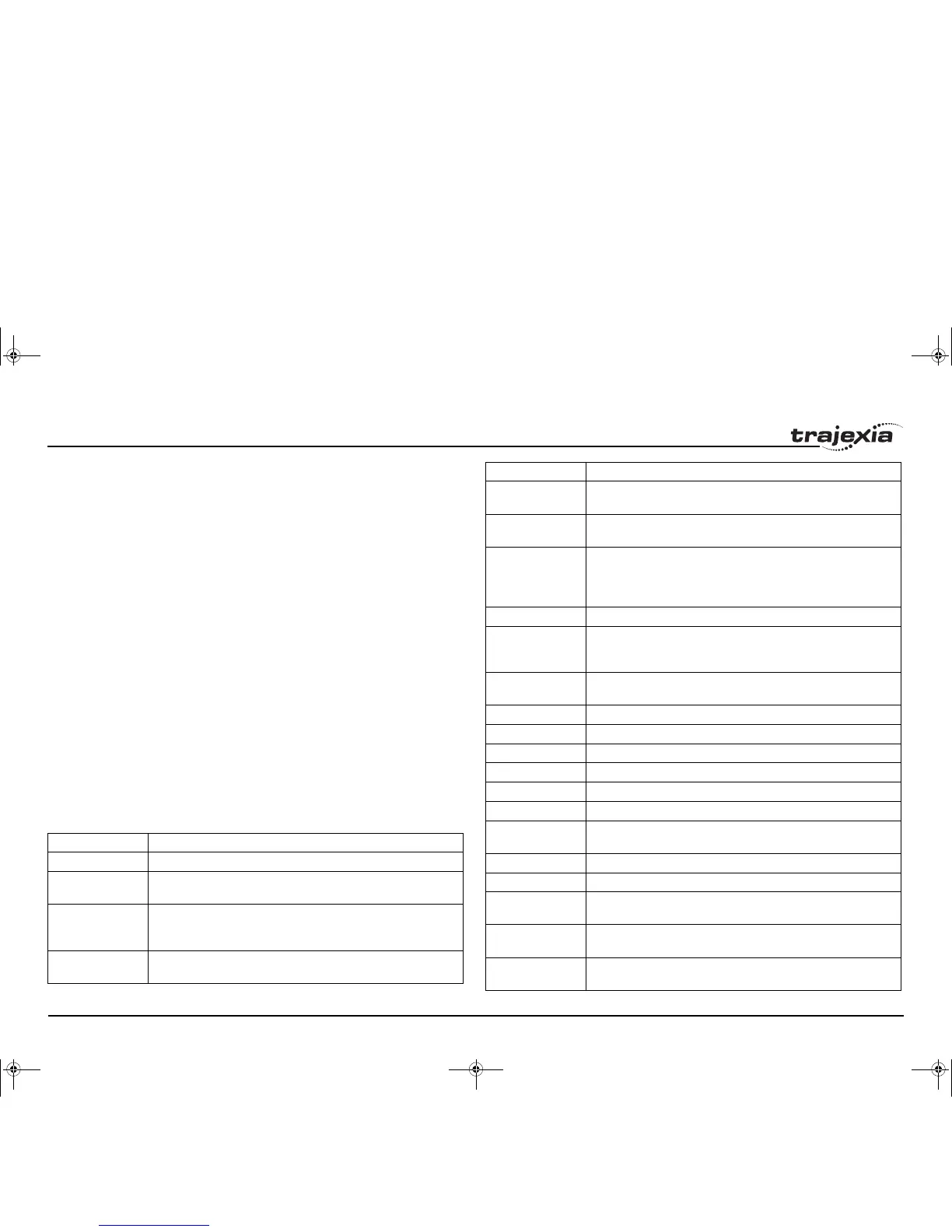

3.1.1 Axis commands

/i

Name Description

ACC Changes the ACCEL and DECEL at the same time.

ADD_DAC Sum to the DAC value of one axis to the analogue output of the

base axis.

ADDAX Sets a link to a superimposed axis. All demand position movements

for the superimposed axis will be added to any moves that are cur-

rently being executed.

B_SPLINE Expands the profile stored in TABLE memory using the B-Spline

mathematical function.

BASE Used to set the base axis to which the commands and parameters

are applied.

CAM Moves an axis according to values of a movement profile stored in

the TABLE variable array.

CAMBOX Moves an axis according to values of a movement profile stored in

the TABLE variable array. The motion is linked to the measured

motion of another axis to form a continuously variable software gear-

box.

CANCEL Cancels the move on an axis.

CONNECT Connects the demand position of an axis to the measured move-

ments of the axis specified for driving_axis to produce an electronic

gearbox.

DATUM Performs one of 7 origin search sequences to position an axis to an

absolute position or reset a motion error.

DEFPOS Defines the current position as a new absolute position.

DISABLE_GROUP Groups axes together for error disabling.

DRIVE_ALARM Monitors the current alarm.

DRIVE_CLEAR Clears the alarm status of the Servo Driver.

DRIVE_READ Reads the specified parameter of the Servo Driver.

DRIVE_RESET Resets the Servo Driver.

DRIVE_WRITE Writes a specific value to the specified parameter of the Servo

Driver.

ENCODER_READ Reads a parameter of the EnDat absolute encoder.

ENCODER_WRITE Writes to a parameter of the EnDat absolute encoder.

FORWARD Moves an axis continuously forward at the speed set in the SPEED

parameter.

HW_PSWITCH Sets on and off the hardware switch on output 0 of the TJ1-FL02

when predefined positions are reached.

MECHATROLINK Initializes MECHATROLINK-II bus and performs various operations

on MECHATROLINK-II stations connected to the bus.

Name Description

I52E-EN-03.book Seite 33 Freitag, 29. Juni 2007 11:55 11

Loading...

Loading...