Page 1-7

GENERAL DESCRIPTION

1

1E4C-E-OMA01-A02-00

1-2 Production Process

This section describes the production mechanism in due order.

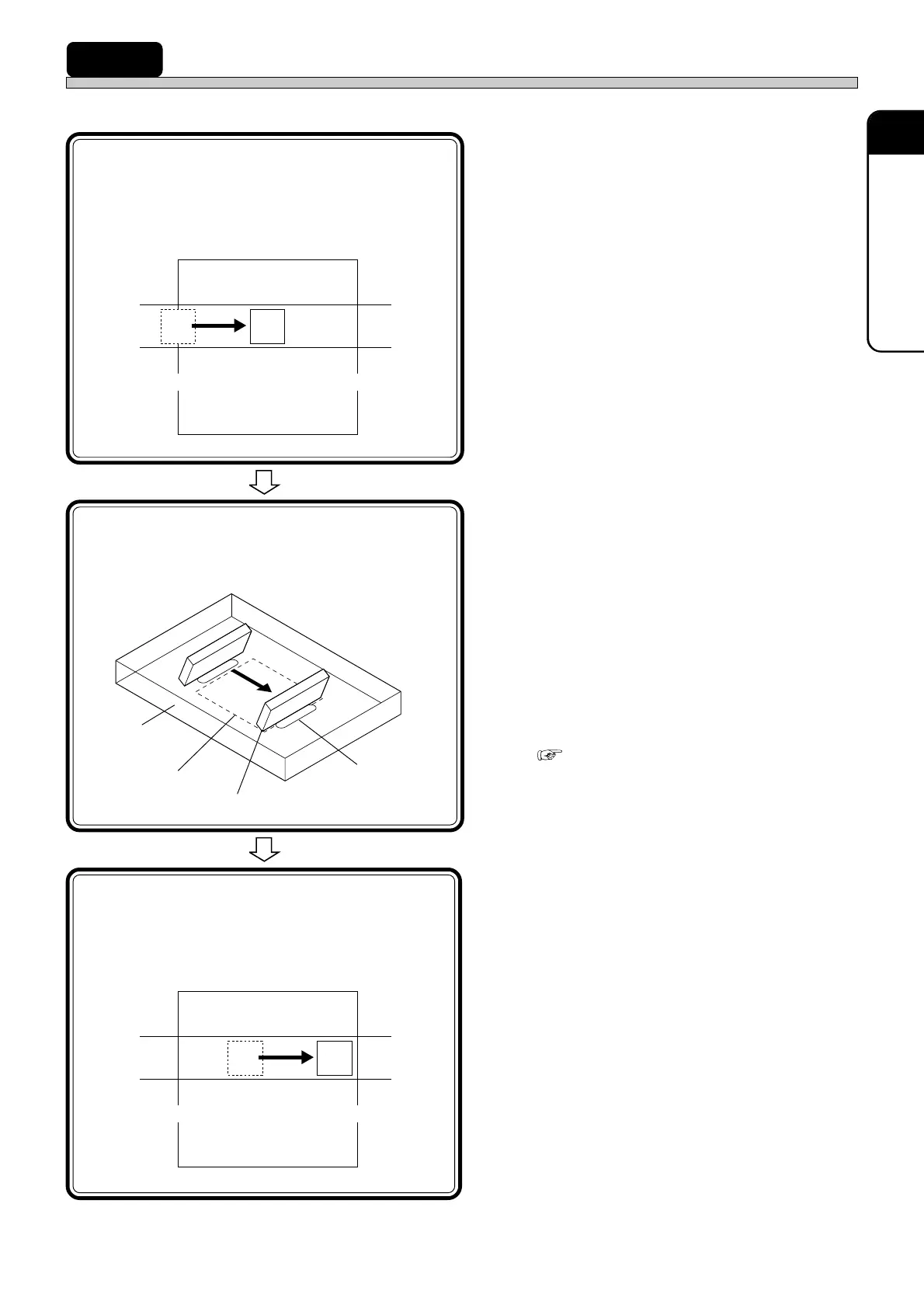

1. Board is transported from the previ-

ous process to the conveyor (left).

2. It is transported from the conveyor

(left) to the board holder.

3. It is clamped in the Y-axis, and the

support rises up.

∗ That the support rises up and then the board is

clamped is also available.

4. The board holder moves to the posi-

tion of recognition camera.

5. The board is recognized.

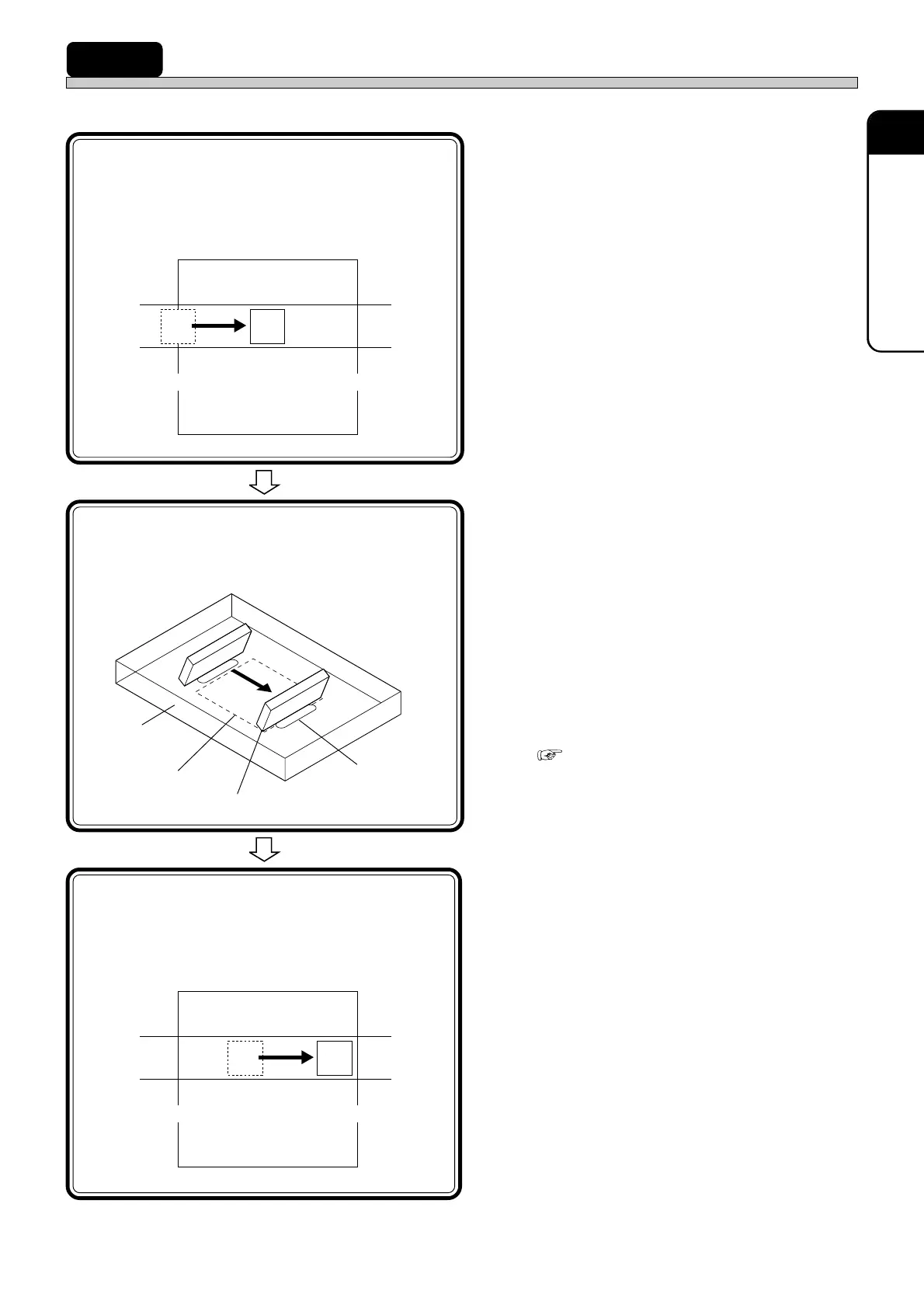

1. The board holder moves to the print-

ing position.

2. The lifter rises up to the surface of

mask, then solder is printed by

squeegee.

3. The lifter lowers from the surface of

mask to the transport height.

∗ When the specified printing count has been

performed, mask is cleaned.

( To the next page)

1. Board is unclamped and the support

lowers.

2. It is transported from the board

holder to the conveyor (right).

3. When the signal comes from the next

process, it is carried out.

1 Transporting board in

• The board transported in from the previous process

is set in the board holder and the machine is ready

for printing.

2 Printing solder

• Solder is printed on board.

3 Transporting board out

• Board is transported out of the board holder to the

next process.

1B4C-039E

1B4C-041E

Previous

process

Next

process

Conveyor (Left) Conveyor (Right)

1B4C-040E

Previous

process

Next

process

Conveyor (Left)

Conveyor (Right)

Mask

Board

Squeegee

Solder

Loading...

Loading...