114 Rockwell Automation Publication 2071-UM001E-EN-P - November 2013

Chapter 9 Maintain and Troubleshoot Your Kinetix 3 Servo Drive

Maintaining Your Kinetix 3

Drive

The Kinetix 3 is designed to function with a minimum of maintenance.

Consider these guidelines to maintain your Kinetix 3 drive:

• Clean the drive periodically, by using an OSHA approved nozzle that

provides compressed air under low pressure, less than 20 kPa (30 psi), to

blow the exterior surface and the vents clean.

• Visually inspect all cables for abrasion.

• Inspect cable connectors for proper seating and signal continuity end-to-

end.

General Troubleshooting

Refer to the Fault Codes section below to identify anomalies, potential causes,

and appropriate actions to resolve the anomalies. If anomalies persist after

attempting to troubleshoot the system, please contact your Allen-Bradley

representative for further assistance. To determine if your Kinetix 3 drive has an

error, refer to the table immediately below.

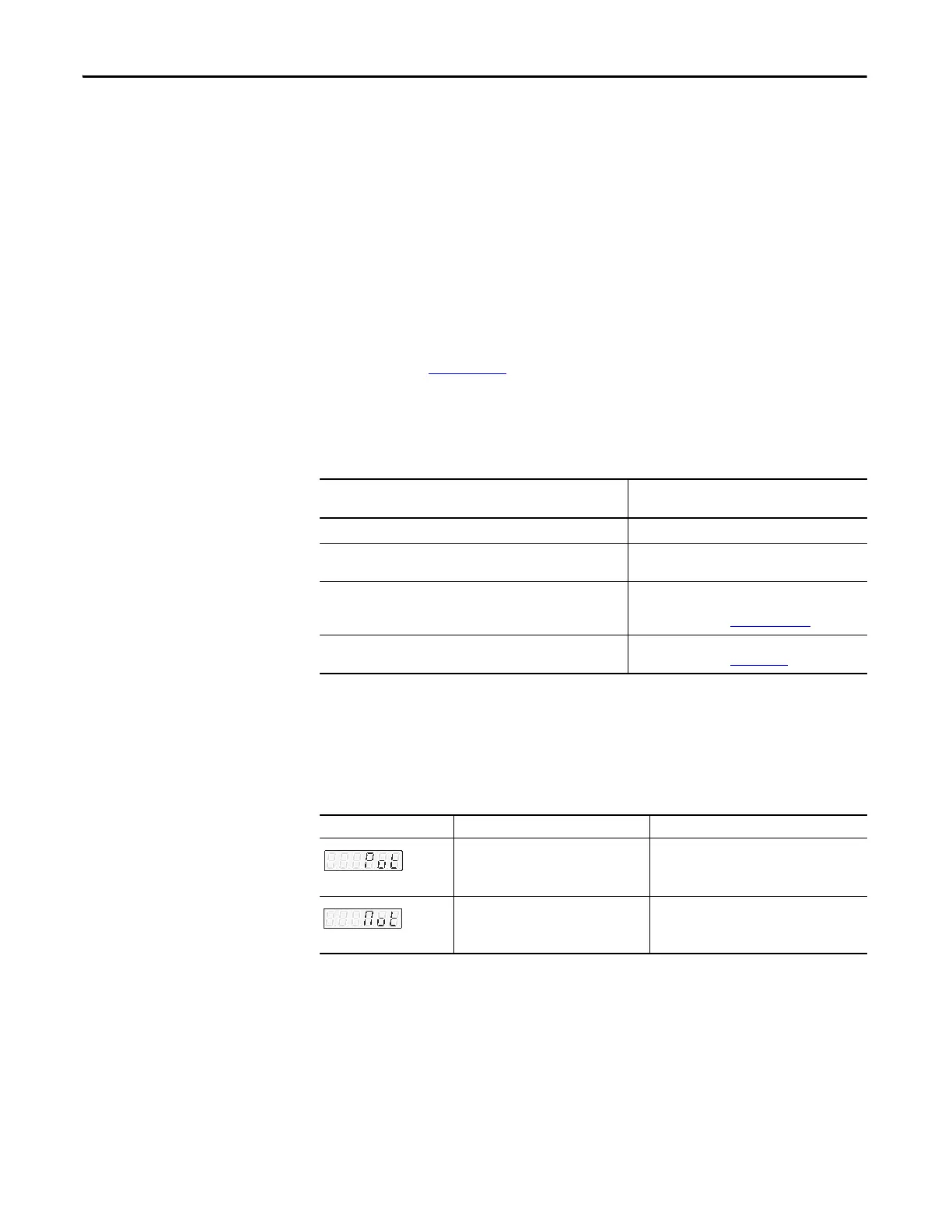

Overtravel Condition

Overtravel displays (see the following table) occur if the drive detects an

overtravel condition.

If the Main Power and Control Power Status Indicators are ON

and the Status Display on the Drive is

Then

Displays ‘rdy’ in the three right-most characters. The Kinetix 3 drive is ready.

Displays ‘Pot’ or ‘not’. The Kinetix 3 drive encountered an Overtravel

Condition and motion restrictions are in effect.

Displays a three-digit warning message. The Kinetix 3 drive is functional, but a drive warning

appears.

Proceed to the section Warning Messages

.

Alternates between a three-digit error code and

a six-digit text message.

An Kinetix 3 drive error has occurred.

Proceed to the section Error Displays.

Overtravel Display Possible Cause Action/Solution

Positive Overtravel

A Positive Overtravel condition is detected. Apply motion in a negative direction to move

off of overtravel limit switch.

Negative Overtravel

A Negative Overtravel condition is

detected.

Apply motion in a positive direction to move off

of overtravel limit switch.

Loading...

Loading...