154 Rockwell Automation Publication 2198-UM001M-EN-P - November 2022

Chapter 8 Remove and Replace Servo Drives

Remove and Replace

Kinetix 5500 Servo Drives

Follow these steps to remove and replace servo drives from the panel.

Remove Power and All Connections

1. Verify that all control and input power has been removed from the

system.

2. Wait five minutes for the DC bus to discharge completely before

proceeding.

3. Label and remove all wiring connectors from the drive that you are

removing.

To identify each connector, refer to Kinetix 5500 Connector Data on

page 58.

4. Remove the shared-bus input wiring connectors, T-connectors, and

busbars from the drive you are removing.

See Shared-bus Connection System on page 47

.

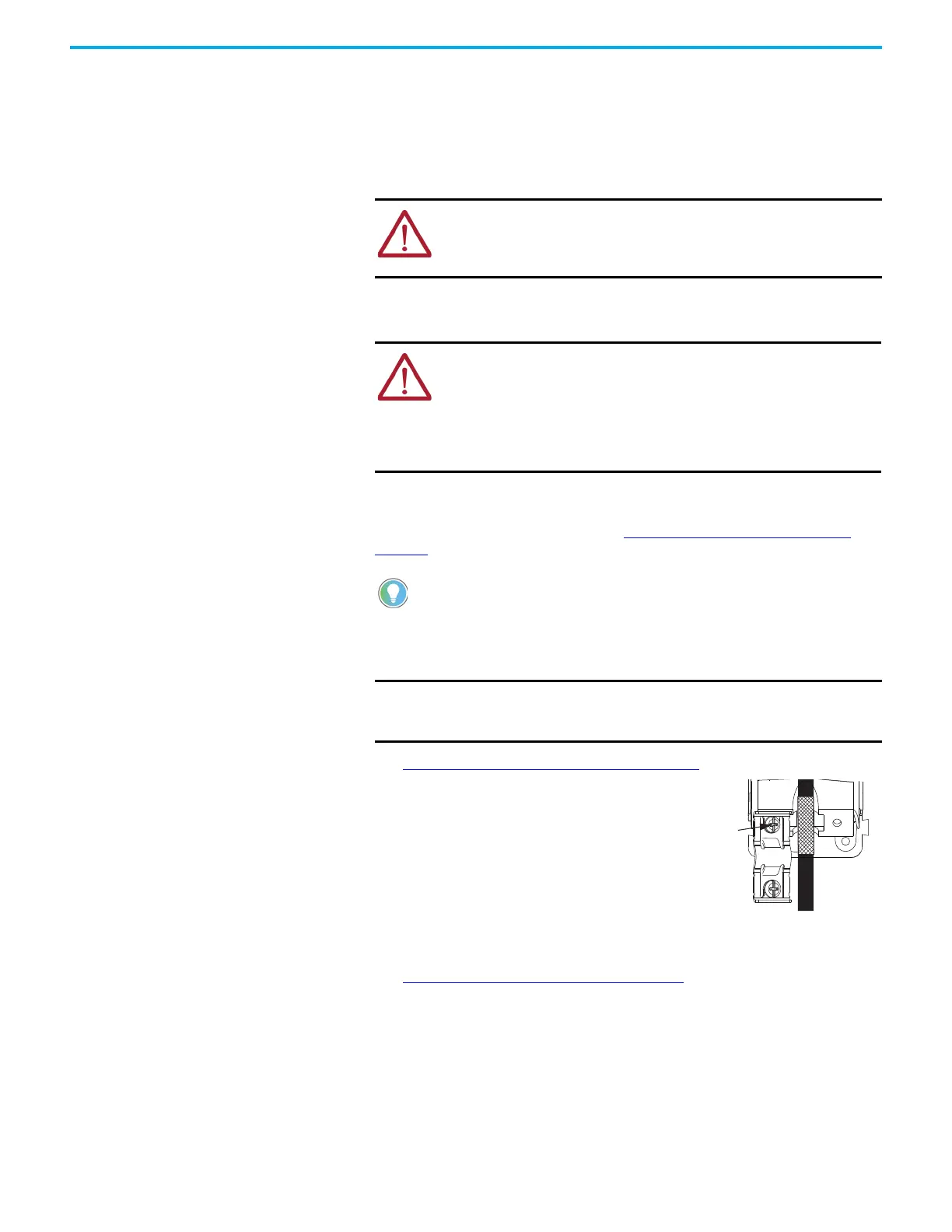

5. Use a screwdriver to loosen the

two cable clamp screws, removing

the screw on the right.

6. Remove the single motor cable from the cable shield clamp.

7. Remove the ground screw and braided ground strap.

See Ground the System Subpanel on page 74

.

ATTENTION: To avoid shock hazard or personal injury, make sure

that all power has been removed before proceeding. This system can

have multiple sources of power. Multiple disconnect switches can be

required to de-energize the system.

SHOCK HAZARD: This product contains stored energy devices. To

avoid the hazard of electrical shock, verify that the voltage on the

capacitors has been discharged before attempting to service, repair,

or remove this unit. Do not attempt the procedures in this document

unless you are qualified to do so and are familiar with solid-state

control equipment and the safety procedures in publication NFPA

70E.

You do not need to remove the shunt (RC) connector, unless there

is an external shunt that is wired to it.

IMPORTANT DC bus T-connectors latch on both sides when inserted into the

drive. To remove the DC bus T-connector, at least one latch must

be pried away with a non-conductive probe.

Retention Screw

(loosen, do not remove)

Motor Cable

Loading...

Loading...