Rockwell Automation Publication 2198-UM001M-EN-P - November 2022 161

Chapter 9 Kinetix 5500 Safe Torque Off - Hardwired Safety

Probability of Dangerous

Failure Per Hour

Safety-related systems are classified as operating in a High-demand/

continuous mode. The SIL value for a High-demand/continuous mode safety-

related system is directly related to the probability of a dangerous failure

occurring per hour (PFH).

PFH calculation is based on the equations from IEC 61508 and shows worst-

case values. Table 72

provides data for a 20-year proof test interval and

demonstrates the worst-case effect of various configuration changes on the

data.

l

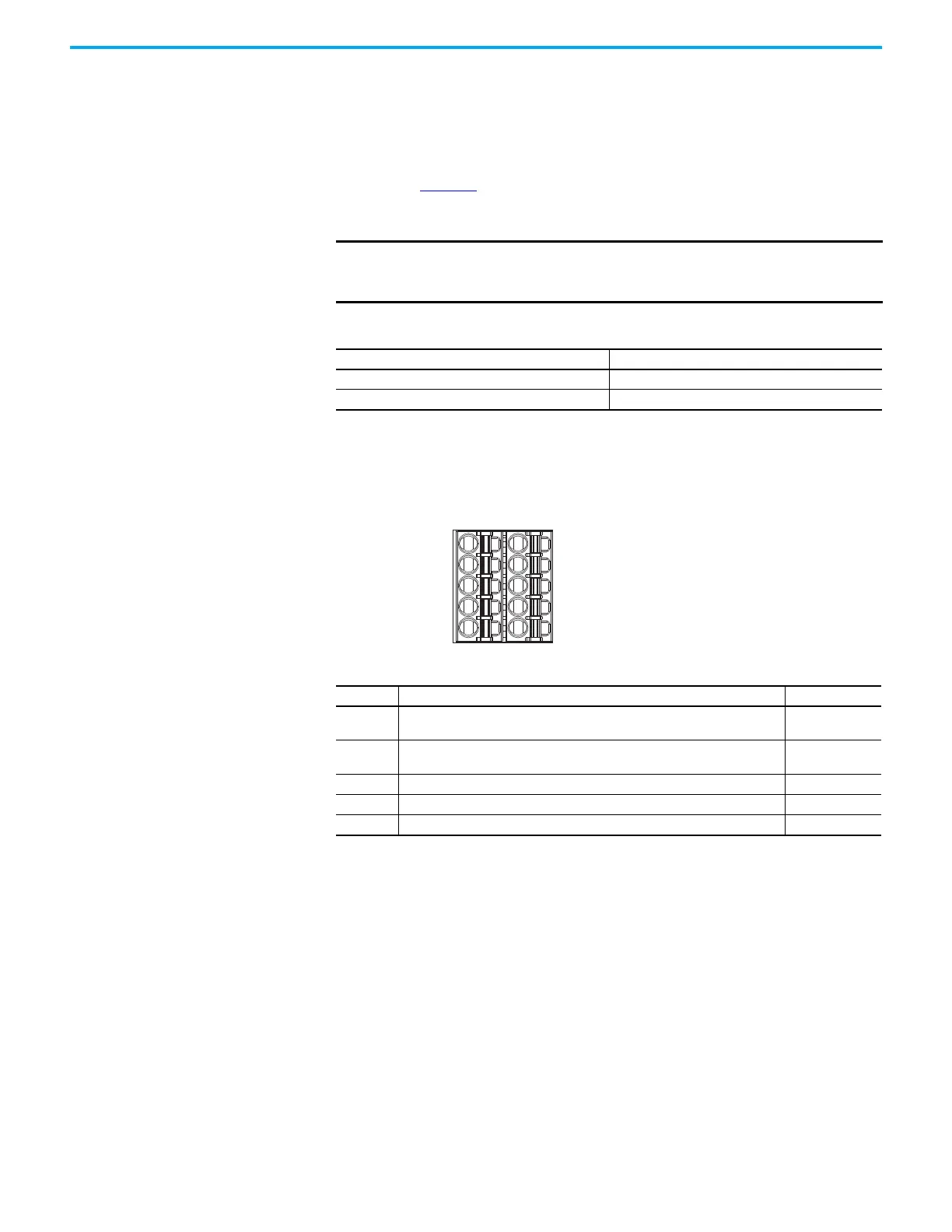

Safe Torque Off Connector

Data

The 10-pin connector consists of two parallel 5-pin rows for cascading safety

connections from drive-to-drive in multi-axis configurations.

Figure 75 - Pin Orientation for 10-pin Safe Torque Off (STO) Connector

IMPORTANT Determination of safety parameters is based on the assumptions that

the system operates in High-demand mode and that the safety

function is requested at least once every three months.

Table 72 - PFH for 20-year Proof Test Interval

Attribute Value

PFH (1e-9) 0.35

Proof test (years) 20

Table 73 - Safe Torque Off (STO) Connector Pinouts

STO Pin Description Signal

1

Safety bypass plus signal. Connect to both safety inputs to disable the STO

function.

SB+

2

Safety bypass minus signal. Connect to safety common to disable the STO

function.

SB-

3 STO input 1 (SS_IN_CH0). S1

4 STO input common (SCOM). SC

5 STO input 2 (SS_IN_CH1). S2

Loading...

Loading...