DK00027.fm

REPAIR MANUAL

BRP-Powertrain

Effectivity: 125 MAX/125 Junior MAX/125 Mini

MAX/125 Micro MAX

Edition 2 / Rev. 0

Chapter 5

Page 29

December 01/2010

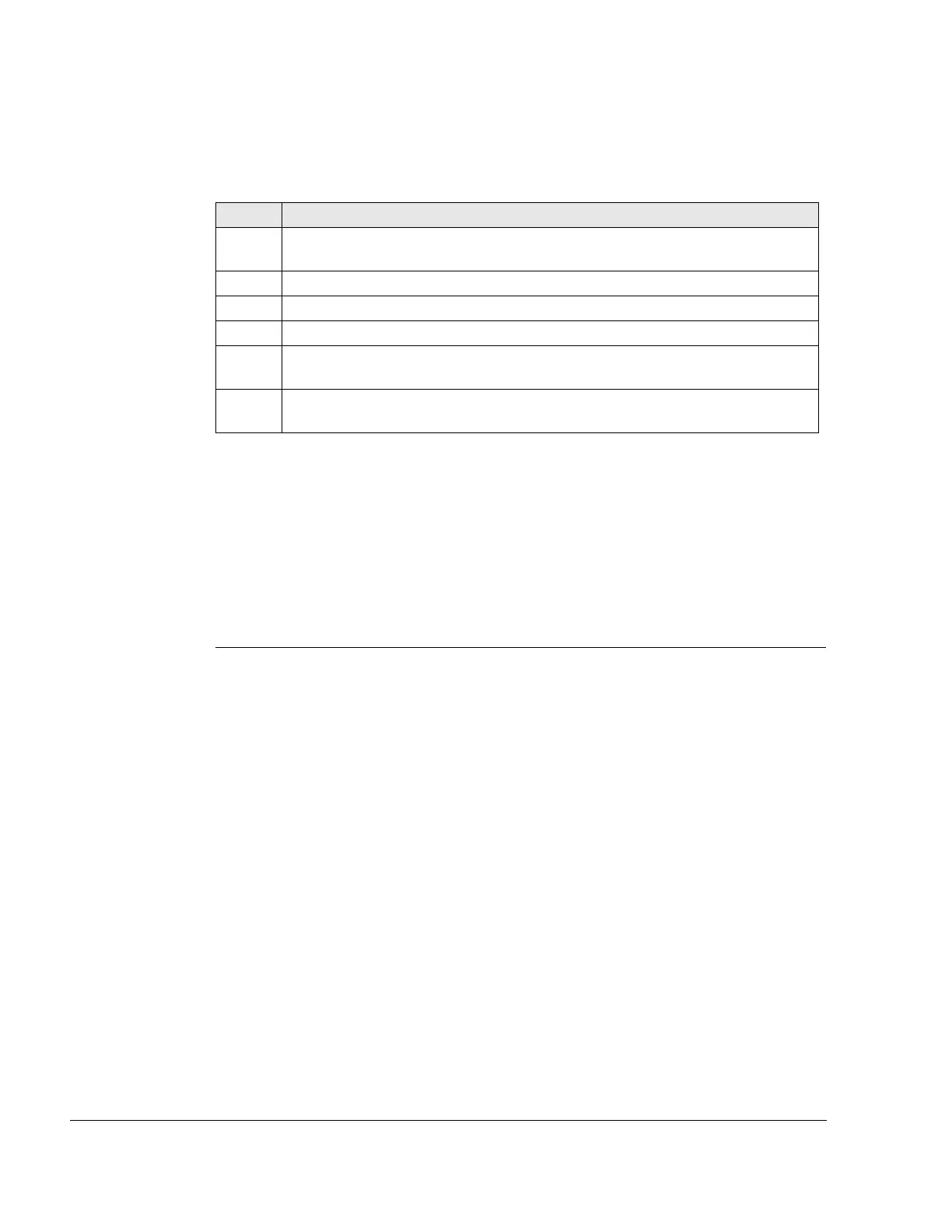

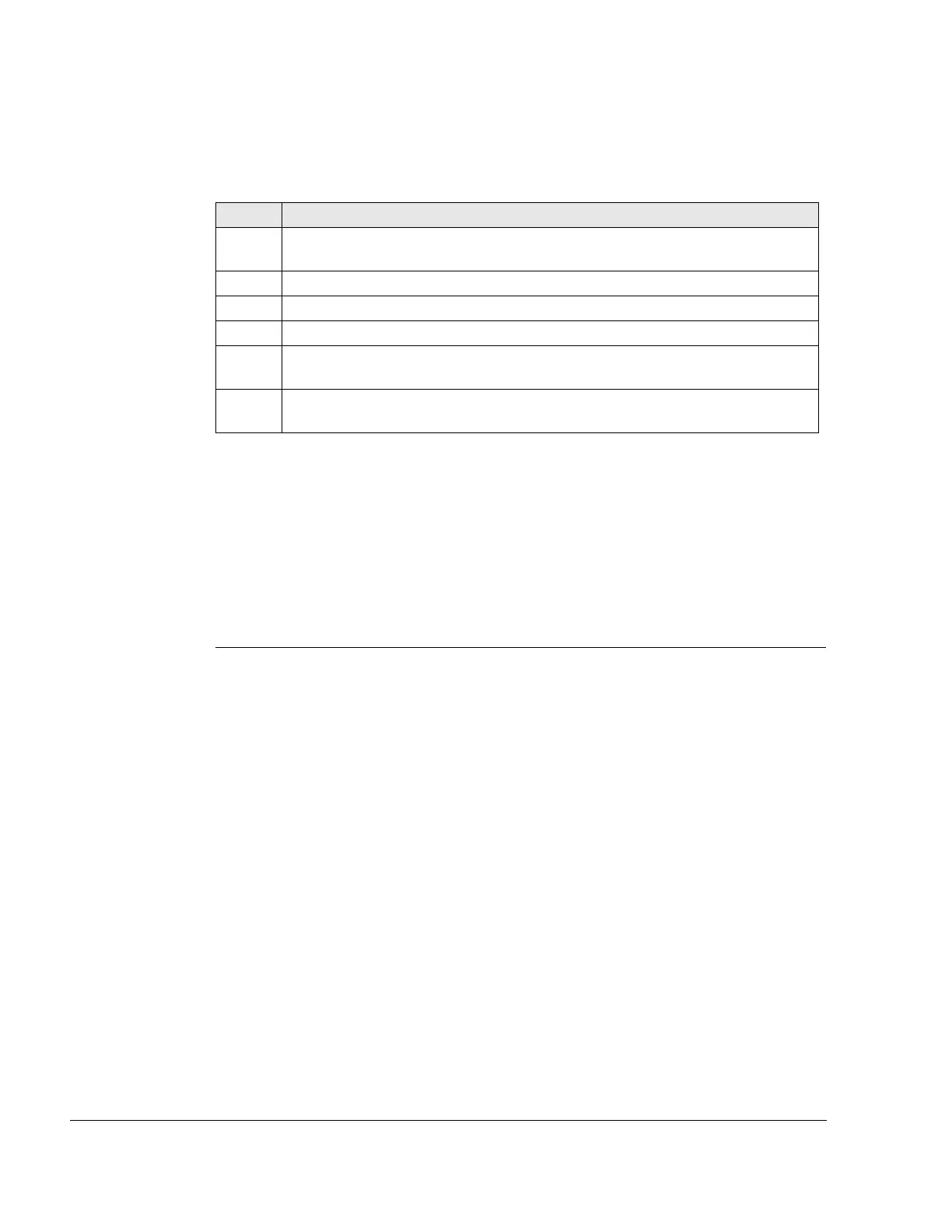

4.3) Inspection of crankcase

Instructions See Figure 18.

NOTES: Oil all grooved ball bearings and the needle bearings with

engine oil before inspection. The inside ring of the bearing

must rotate freely and easily without pressure and there

must not be any noise. Replace the bearing in case of

doubt.

If one of the two roller bearings of the crankshaft or balance

shaft is defective, both roller bearings must be replaced.

NOTES: If the roller bearings of the crankshaft or balance shaft are

replaced, all oil seals for shaft must be replaced.

Step Procedure

1 Clean both case halves, grooved ball bearings and all bearing seats thorough-

ly with a standard cleaning agent.

2 Check both halves (1) for cracks and damage (visual inspection).

3 Check sealing surfaces (2) for damage (visual inspection).

4 Check threads (3) for cleanliness and smoothness.

5 Check that main bearing oil holes (4) are open and clean with compressed air

as required.

6 Inspect the ball and needle bearings for ease of running and erosion of mate-

rial (pitting).

Loading...

Loading...